Internal-combustion engine

A technology for internal combustion engines and combustion chambers, applied in the field of piston reciprocating internal combustion engines, can solve the problems of low combustion efficiency, slow piston down speed, low fuel economy, etc., and achieve the goals of reducing costs, improving adaptability, and improving the power-to-mass ratio of the whole machine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

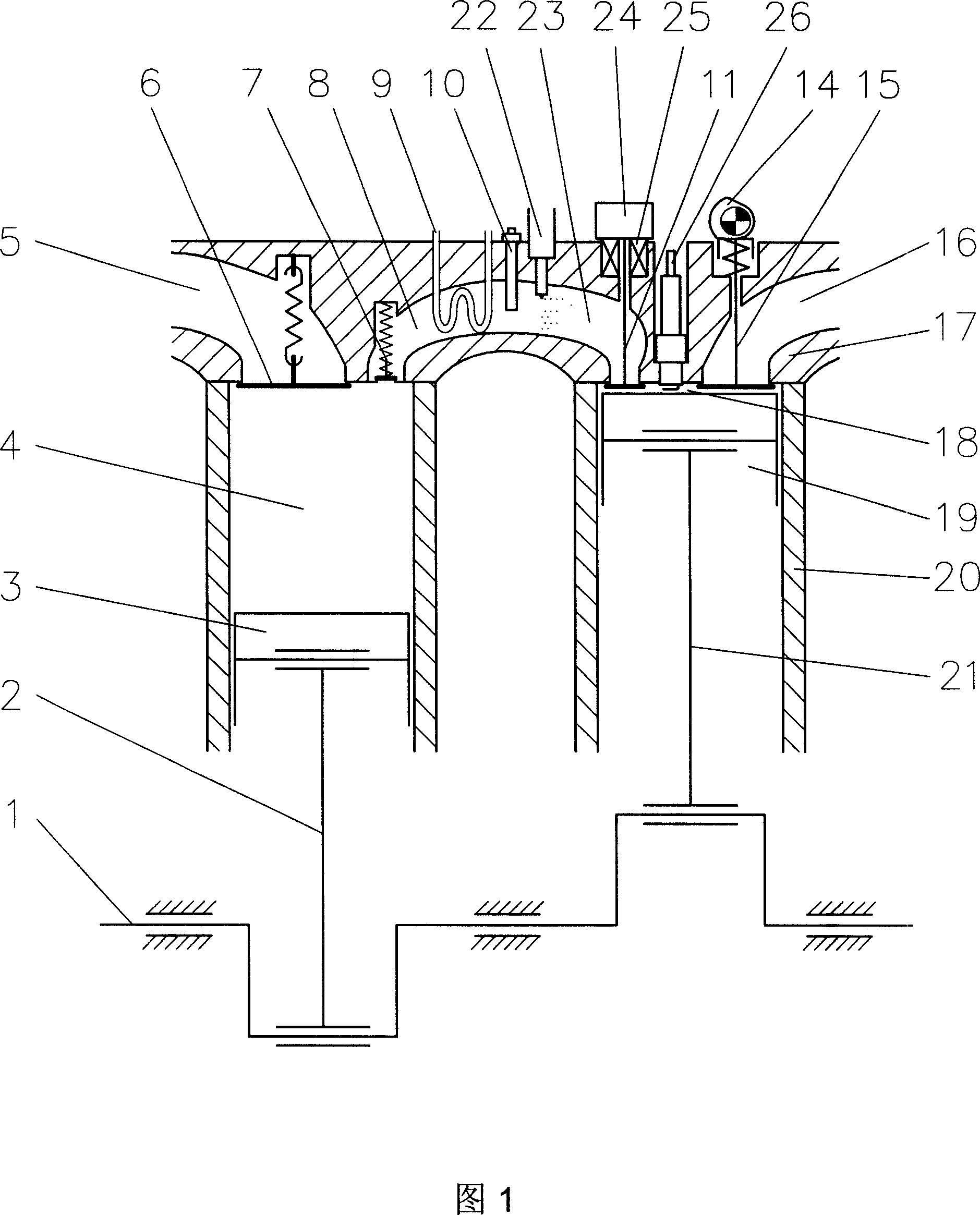

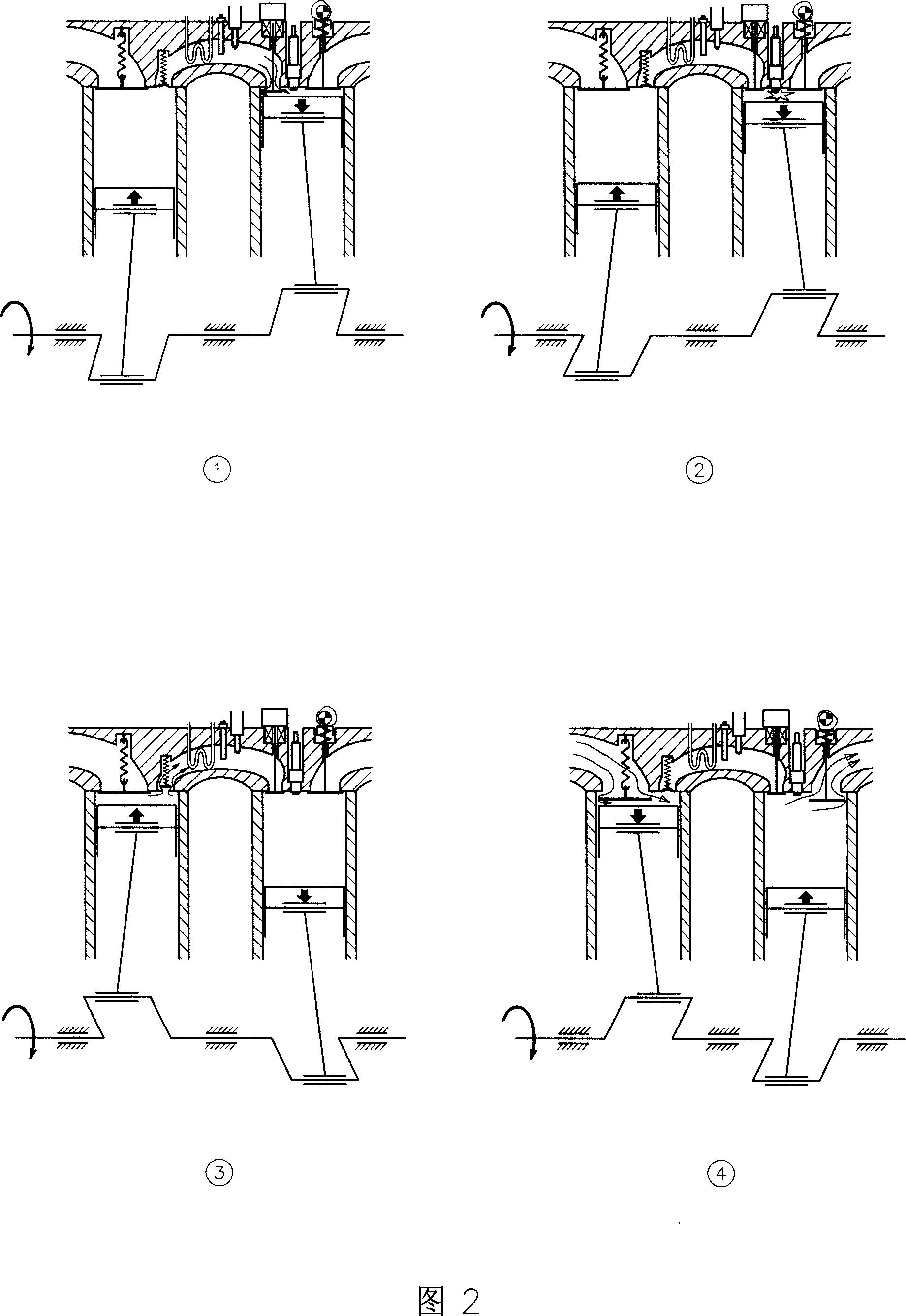

[0035] Embodiment 1, in conjunction with Fig. 1 and Fig. 2, in the first embodiment shown, the internal combustion engine works in the ignition mode and uses gasoline as fuel. The combustion chamber 18 unit includes a cylinder block 20, a cylinder head 17, a piston 19, a crankshaft 1 and a connecting rod 21. The piston 19 reciprocates in the cylinder block 20 and is connected to the crankshaft 1 through the connecting rod 21. The top space of the piston 19 is formed by the cylinder head 17. The combustion chamber 18 is sealed and formed. In the cylinder head 17, an intake valve 11, an exhaust valve 15 and a spark plug 26 are arranged on the top of the combustion chamber 18. The intake valve 11 is driven by the intake valve driving device 24, and the exhaust valve 15 is driven by The exhaust valve cam 14 is driven, the intake valve driving device 24 is provided with an intake valve position sensor 25, and an air compression unit 4 is also provided in the cylinder block 20 outsi...

Embodiment 2

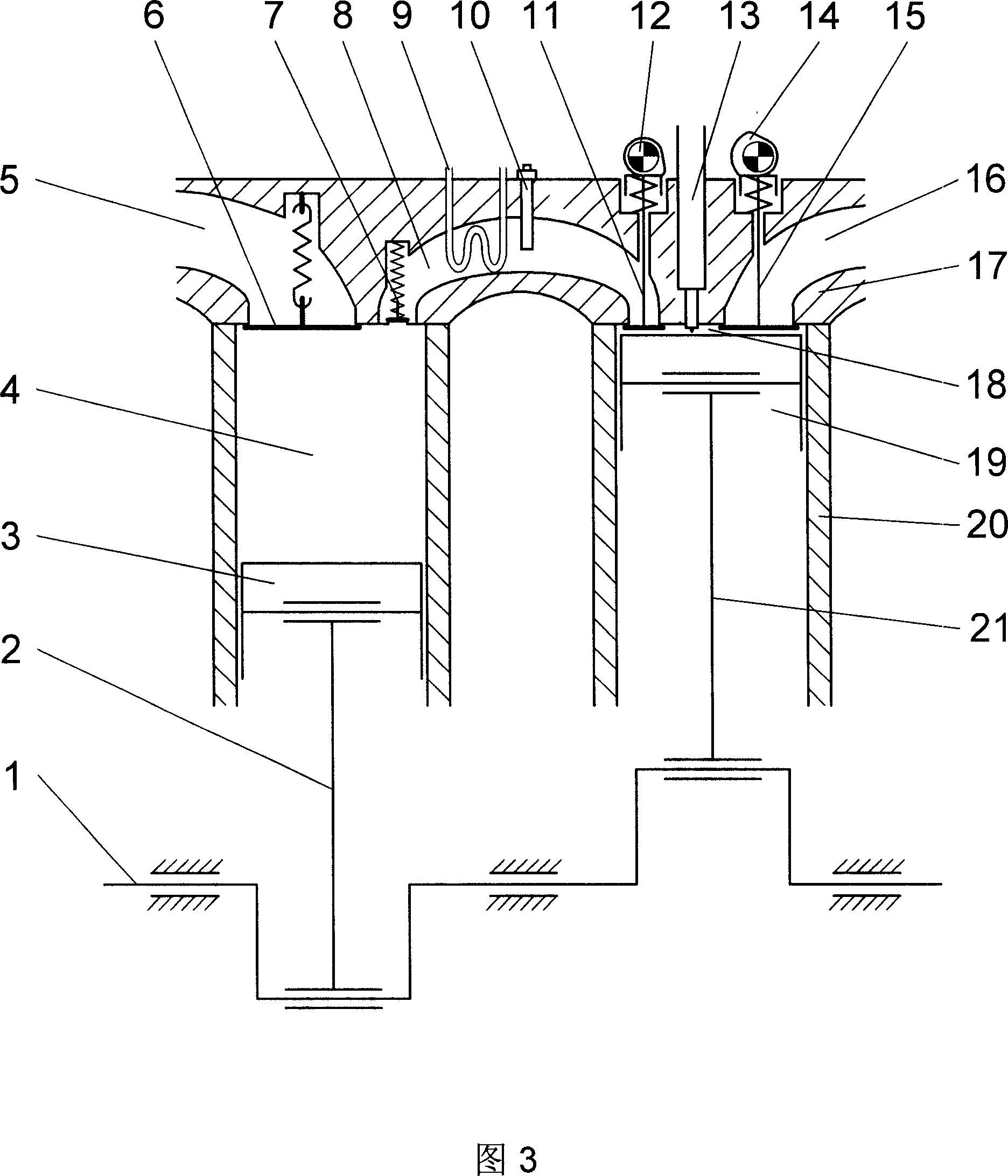

[0037] Embodiment 2, referring to Fig. 3 and Fig. 4, in the second embodiment shown, the internal combustion engine works in compression ignition mode and uses diesel as fuel. The combustion chamber 18 unit includes a cylinder block 20, a cylinder head 17, a piston 19, a crankshaft 1 and a connecting rod 21. The piston 19 reciprocates in the cylinder block 20 and is connected to the crankshaft 1 through the connecting rod 21. The top space of the piston 19 is formed by the cylinder head 17. The combustion chamber 18 is sealed and formed. In the cylinder head 17, the upper part of the combustion chamber 18 is provided with an intake valve 11, an exhaust valve 15 and a fuel injector 13. The intake valve 11 is driven by the intake valve cam 12, and the exhaust valve 15 is driven by the intake valve cam 12. The exhaust valve cam 14 is driven, and an air compression unit 4 is also provided in the cylinder block 20 outside the combustion chamber 18. The air compression unit 4 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com