Temperature-regulating ink box

A technology of temperature adjustment and ink cartridges, which is applied in printing and other directions, and can solve problems such as lack of temperature adjustment capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

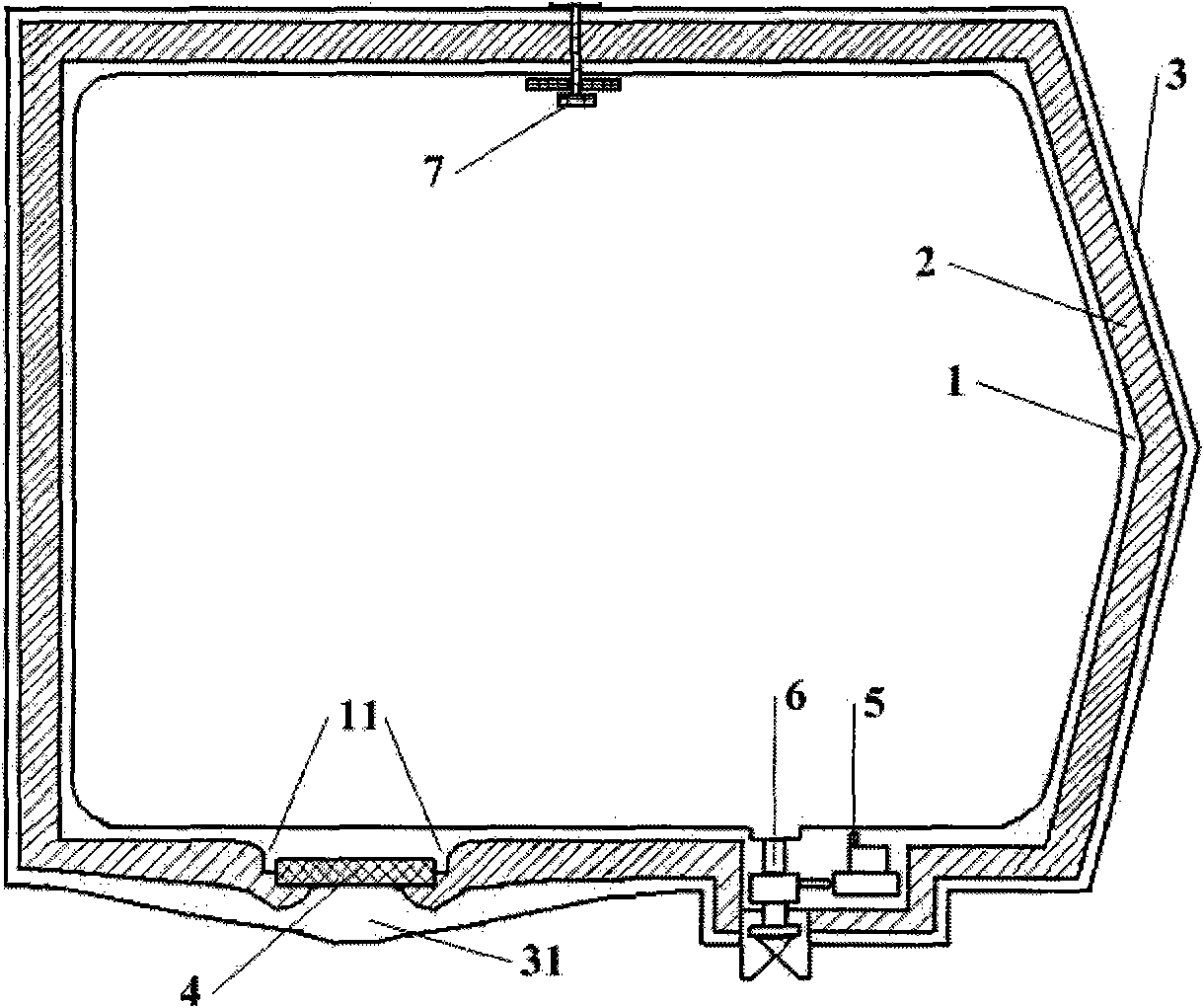

[0011] Such as figure 1 As shown, similar to the traditional ink cartridge, the temperature-regulating ink cartridge also includes three parts: the shell, the ink outlet control port (6) and the air guide hole (7). There are three layers (2) and an outer layer (3), and a temperature regulation chip (4) and a temperature sensor (5) are embedded in the shell. Among them, the inner tank (1) is made of a metal material with excellent thermal conductivity, and the entire inner tank is designed with a concave card slot (11) that can be in close contact with the temperature regulation chip; the heat insulation layer (2) is made of It is made of a material with excellent thermal insulation; the outer layer (3) is also made of a metal material with excellent thermal conductivity, and the entire outer layer (3) is designed with a protrusion (31) that can be in close contact with the temperature regulation chip ); the temperature-regulating chip (4) is composed of semiconductor refriger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com