Intelligent ink supply control system for metal sheet printing and method thereof

A metal sheet and control system technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of changes in ink supply, complex operation process, low efficiency, etc., to meet printing needs, reduce resource waste, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

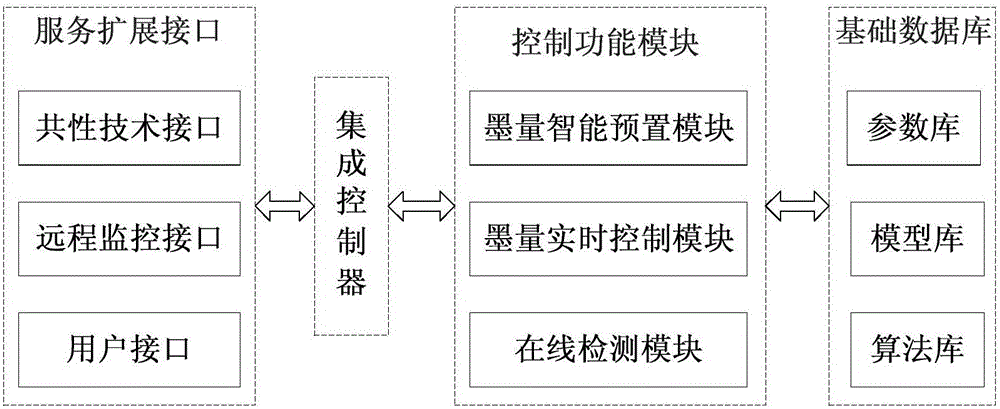

[0054] figure 1 It is a specific implementation case of an intelligent ink supply control system for metal sheet printing and coating in the present invention, which includes: service expansion interface, controller, control function, basic database, etc. The common technology interface is used for production information management and other services; the remote monitoring interface is used for equipment status monitoring, fault diagnosis and remote service, etc.; the user interface is used to meet user-specific service requirements. The basic database provides the required basic data, process parameters, algorithms / processes, etc. for the decision-making of the control process. Online detection is used to detect the quality of printed products, specifically the measurement and identification of parameters related to ink volume, providing support for real-time adjustment of ink volume. The intelligent preset of ink volume is based on the ink supply needs of different areas of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com