Automatic cutting mechanism for flat iron angle steel for manufacturing fan

A technology of automatic cutting and flat iron, applied in the direction of manufacturing tools, metal sawing equipment, sawing machine, etc., can solve the problems affecting production efficiency, difficult to meet the processing needs of continuous cutting and mass production, and manual retrieving, to achieve Guarantee cutting accuracy and cutting quality, improve cutting processing efficiency, and stabilize the cutting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

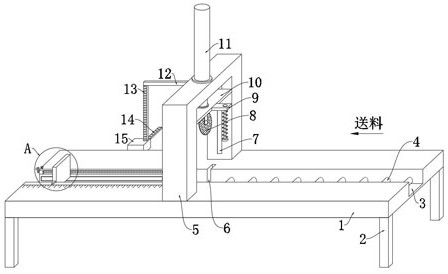

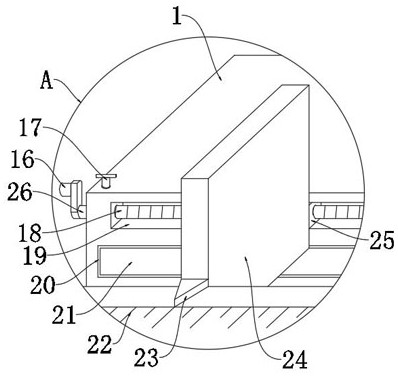

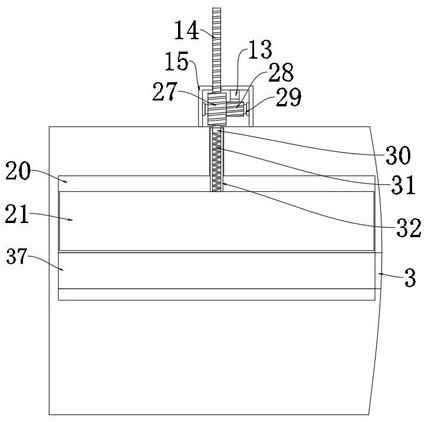

[0027] refer to Figure 1-6 , a flat iron angle steel automatic cutting mechanism for manufacturing fans, comprising a cutting table 1, and the bottom of the cutting table 1 is provided with a leg 2, the upper end of the cutting table 1 is provided with a feeding groove 3 along the feeding direction, and the upper end of the cutting table 1 is provided with There is a mounting frame 5 positioned above the feeding trough 3, the top of the mounting frame 5 is provided with a lifting cylinder 11, and the telescoping end of the lifting cylinder 11 penetrates the mounting frame 5 downwards and is fixed with a mobile seat 10. The inner wall of the mounting frame 5 is provided with a The guide groove 7 that the moving seat 10 is adapted to, the two ends of the moving seat 10 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com