Integrated biological 3D printer printing cavity body environment control system and control method

A 3D printer and control system technology, applied in the field of 3D printing, can solve the problems of poor stability of the controlled environment, affecting the printing process, temperature and humidity, air volume, and wind speed of the printing environment cannot be adjusted independently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

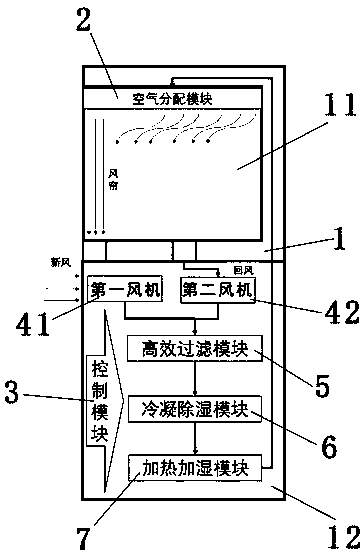

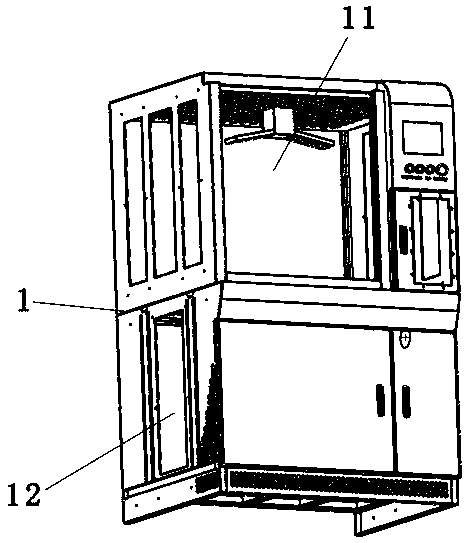

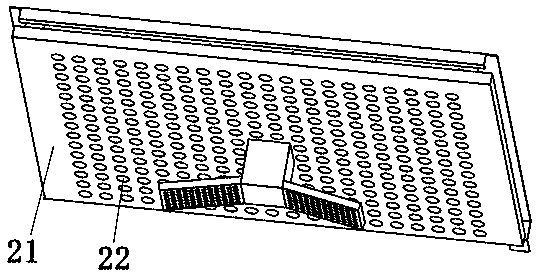

[0037] Such as Figure 1 to Figure 3 As shown, an integrated biological 3D printer printing chamber environment control system, which includes a main housing 1, and the interior of the main housing 1 is divided into a printing chamber 11 and an environmental control chamber 12 spaced from each other up and down. The environment control cavity 12 is provided with a control module 3, and a ventilation module 4, a high-efficiency filter module 5, a condensation dehumidification module 6 and a heating and humidifying module 7 connected in sequence, and the heating and humidifying module 7 is connected to the air distribution module 2 , the air distribution module 2 is arranged on the top of the printing cavity 11, the ventilation module 4 communicates with the inside of the printing cavity 11 and the outside of the main casing 1, the ventilation module 4, the high-efficiency filtration module 5, the condensation dehumidification The module 6 , the heating and humidifying module 7 ...

Embodiment 2

[0046] Such as Figure 4 As shown, an integrated biological 3D printer printing cavity environment control method, which includes the following steps:

[0047] S1. Receive the preset data about the printing chamber 11, the preset data are respectively the preset pressure of 1.2atm, the preset temperature of 37°C and the preset humidity of 25%, and control the condenser of the condensation dehumidification module 6 according to the preset data Pre-cool to 4°C, control the heater in the heating and humidifying module 7 to preheat to 100°C, and the humidifier to preheat to 45°C;

[0048] S2. Control the ventilation module 4 to send a sufficient amount of air into the environment control cavity 12, and determine the control parameters of the high-efficiency filtration module 5, the condensation dehumidification module 6, the heating and humidification module 7 and the air distribution module 2 according to the preset data , according to the control parameters to control each modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com