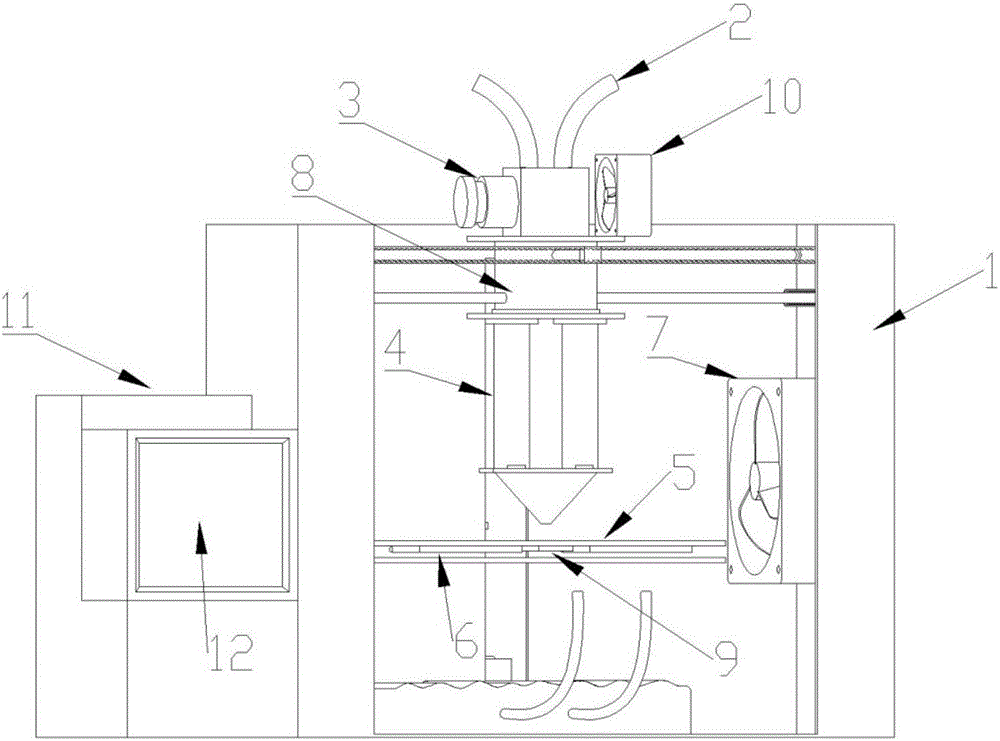

Reaction type 3D printer

A 3D printer and high-temperature reaction technology, applied in 3D object support structures, additive manufacturing, coating devices, etc., can solve problems such as poor hardness, toughness and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

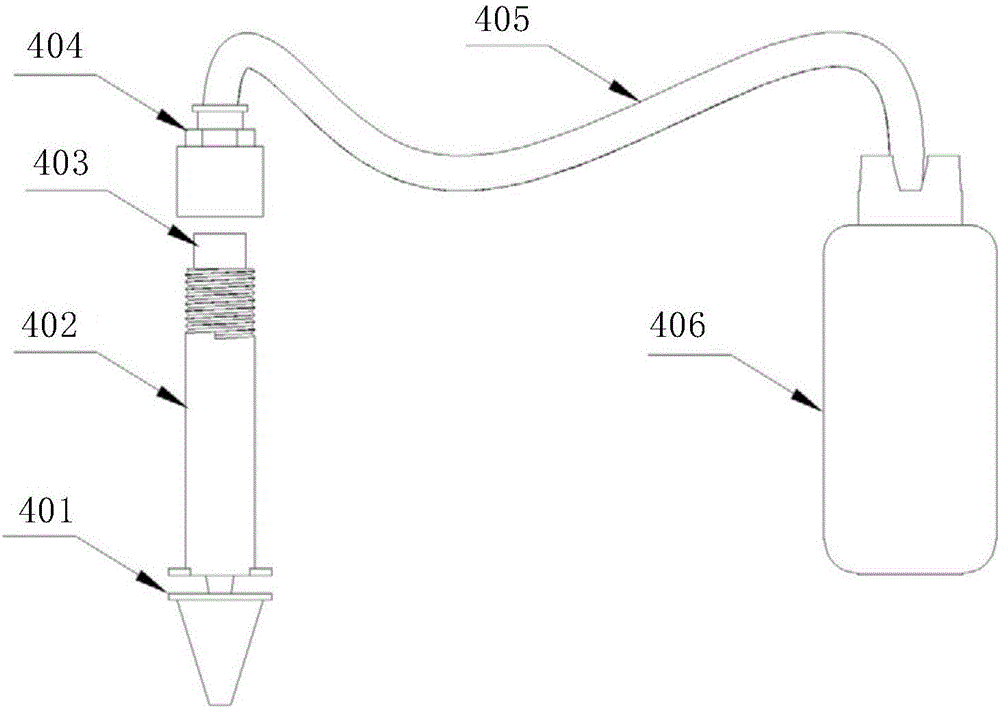

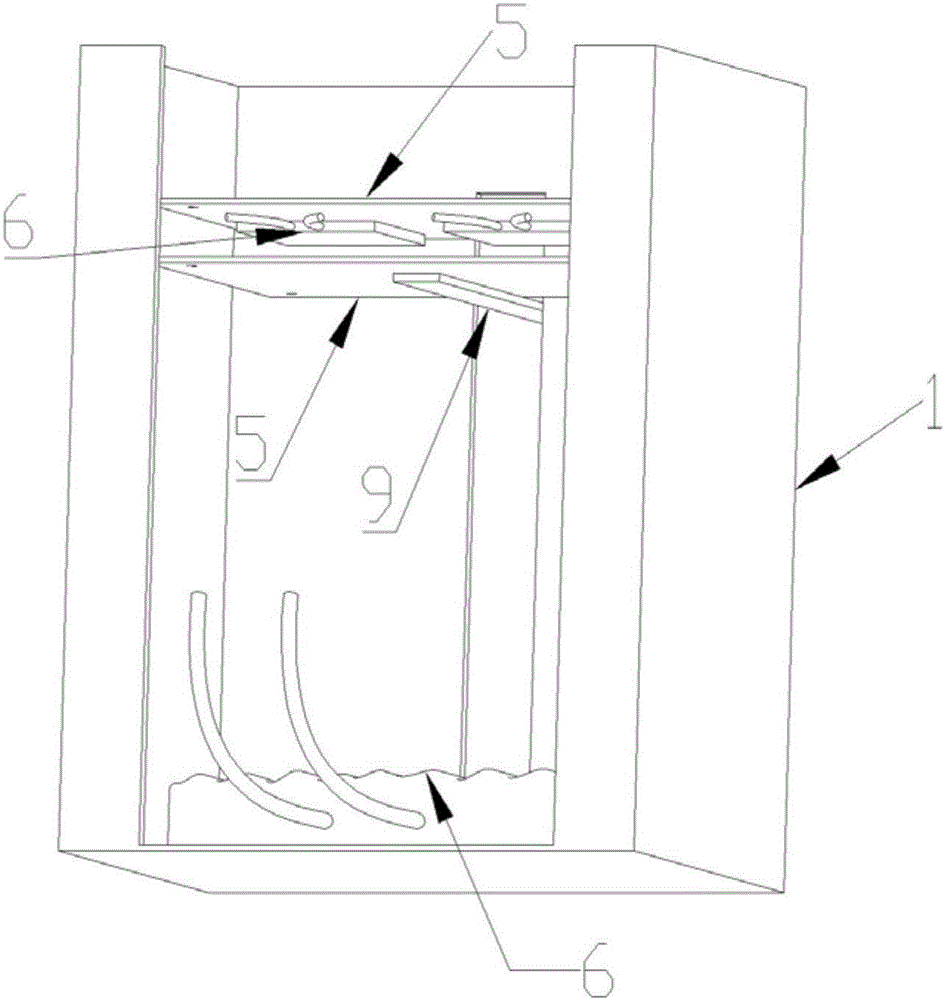

[0043] In this embodiment, there are two storage syringes, namely ① and ②. Fill the molded silicone glue into the syringe ①, and fill the silicone curing agent into the syringe ②. The mass ratio of silica gel and curing agent is 100:2.5. On the 3D printing slicing software, set the wire diameters of ① and ② print heads to 1 and 40 respectively, and set the temperature of the hot bed to 50 degrees for offline printing.

Embodiment 2

[0045] In this embodiment, there are two storage syringes, namely ① and ②. Fill the syringe ① with glue A of epoxy resin AB glue, and the syringe ② with glue B of epoxy resin AB glue. The mass ratio of glue A and glue B is 1:1, and then on the 3D printing slicing software, set the wire diameters of the print heads of ① and ② to 1.75 and 1.75 respectively, and set the temperature of the hot bed to 60 degrees for offline printing .

Embodiment 3

[0047] In this embodiment, there are two storage syringes, namely ① and ②. Fill the syringe ① with 4.5 grams of corn starch, 22 grams of acrylic acid, 9 grams of acrylamide, 4.5 grams of calcium carbonate, 9.5 grams of sodium hydroxide, and 30.5 grams of water; 3.5 grams, 6.5 grams of N,N-methylenebisacrylamide, 10 grams of water. Then, on the 3D printing slicing software, set the wire diameters of ① and ② print heads to 1.75, and set the temperature of the hot bed to 70 degrees for offline printing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com