3D printing device

A 3D printing and equipment technology, applied in the direction of additive processing, etc., can solve the problems of low efficiency, large space occupied by printing equipment, and high cost of printing equipment, so as to improve work efficiency, save printing time, and meet printing needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

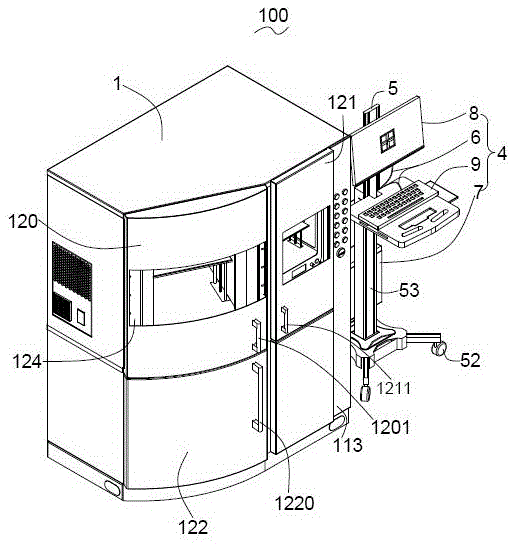

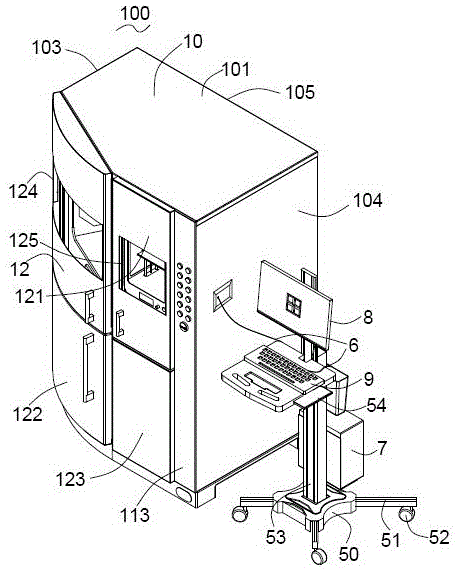

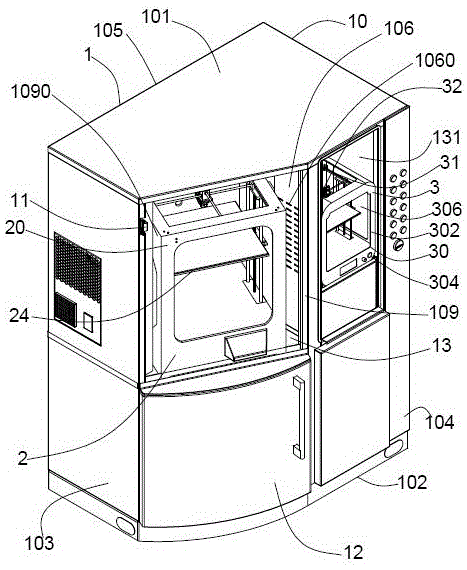

[0052] Figure 1 to Figure 15 Shown is a 3D printing device 100 according to a first embodiment of the present invention, which is used for printing three-dimensional models for medical use or surgical implants. Please refer to Figure 1 to Figure 6 As shown, the 3D printing device 100 includes a housing 1, a first printer 2 and a second printer 3 assembled in the housing 1, a computer system 4 connected to the first printer 2 and the second printer 3 at the same time, and a host computer system 4 of the support frame 5. The first printer 2 may be a Fused Deposition (FDM) printer, or a Stereo Laser Solidification (SLA) printer, or a Selective Laser Sintering (SLS) printer. The second printer 3 may be a Fused Deposition (FDM) printer, or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com