Ultraviolet light-cured offset printing ink with LED as light source

A technology of offset printing ink and ultraviolet light, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of high heat generation, short service life, and difficult drying, and achieve the effects of reduced emissions, clear lines, and excellent curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

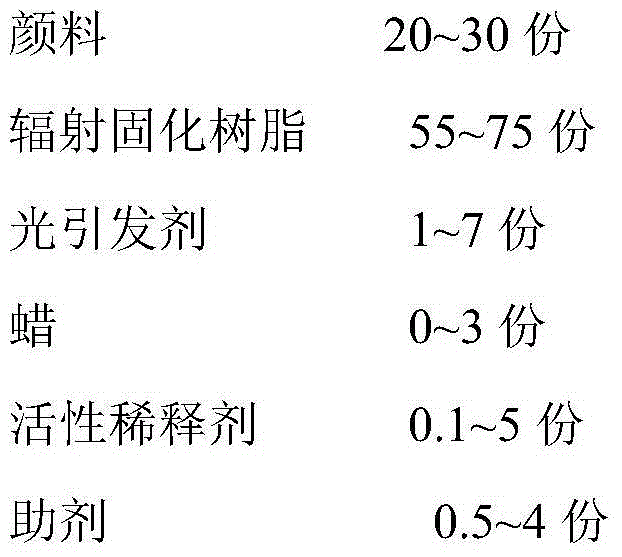

[0030] The formula is shown in the table below, and the amounts of components are all parts by weight.

[0031]

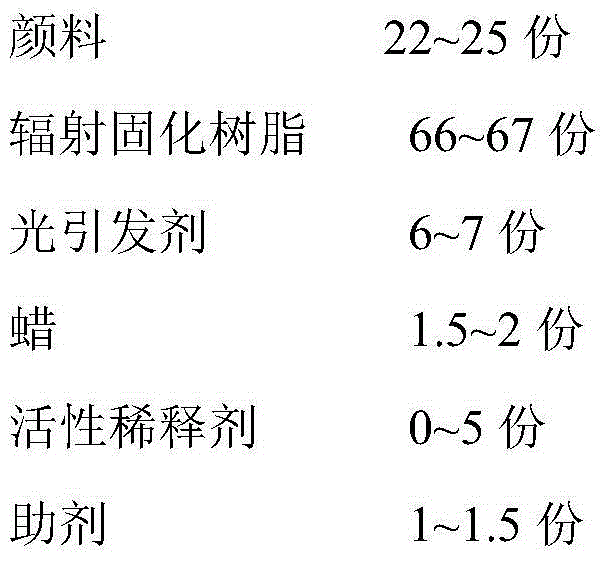

[0032]

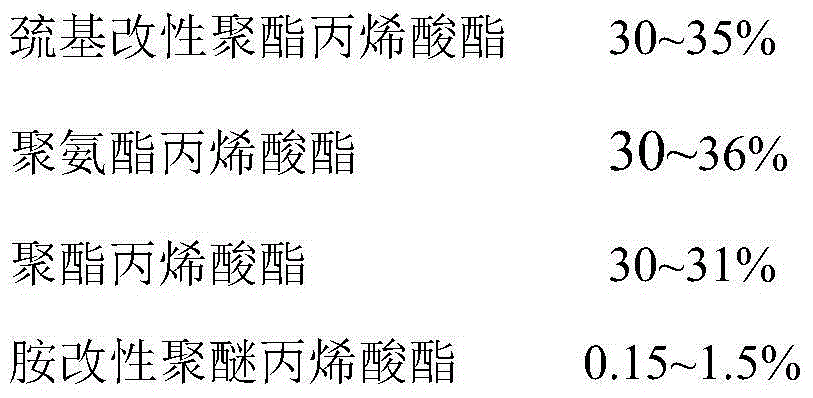

[0033] The mercapto-modified polyester acrylate is LED01.

[0034] Urethane acrylate is EB8602.

[0035] The polyester acrylate is EB830.

[0036] The amine-modified polyether acrylate is PO94F.

[0037] Acid-modified methacrylate is EB168.

[0038] The alpha-aminoketone is Irgacure 379.

[0039] The monoacylphosphine is Darocur TPO.

[0040] Polyethylene wax is PEW1555.

[0041] p-Benzoquinone is UV22.

[0042] Preparation method: Mix the above formula in a batching kettle, stir at 1000rpm / min for 30 minutes, and then fully grind it with a Buhler three-roller until the ink fineness is less than 5um, and then the UV-LED ink for offset printing can be obtained.

[0043] The prepared UV-LED photocurable offset printing ink has a viscosity of 23.5Pa s, a thixotropic ring area of 4.5E+05, (30°C, HAAKE RV1 rheometer, 1 degree cone and plate, and ...

Embodiment 2

[0047]

[0048] The mercapto-modified polyester acrylate is LED01.

[0049] Urethane acrylate is EB284.

[0050] The polyester acrylate is EB546.

[0051] Trimethylolpropane triacrylate is TMPTA.

[0052] The amine-modified polyether acrylate is PO94F.

[0053] Acid-modified methacrylate is EB168.

[0054] The alpha-hydroxy ketone is Darocur 1173.

[0055] The diacylphosphine is Irgacure 819.

[0056] The polypropylene wax is LANCO 1588.

[0057] p-Benzoquinone is UV22.

[0058] Preparation method: Mix the above formula in a batching kettle, stir at 1000rpm / min for 30 minutes, and then fully grind it with a Buhler three-roller until the ink fineness is less than 5um, and then the UV-LED ink for offset printing can be obtained.

[0059] The prepared UV-LED photocurable offset printing ink has a viscosity of 24.2Pa s, a thixotropic ring area of 6.2E+05, (30°C, HAAKE RV1 rheometer, 1 degree cone and plate, and a shear rate of 300s-1 ), at a printing speed of 200m / min, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com