Downward-flow type continuous sand filter and operating method thereof

A sand filter and flow-type technology, applied in the field of sand filters, can solve the problems of reduced sewage treatment efficiency, inability to synchronize, and reduced continuity of filtered sewage, etc., to achieve the effect of ensuring continuous operation, simple structure, and improved sewage filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

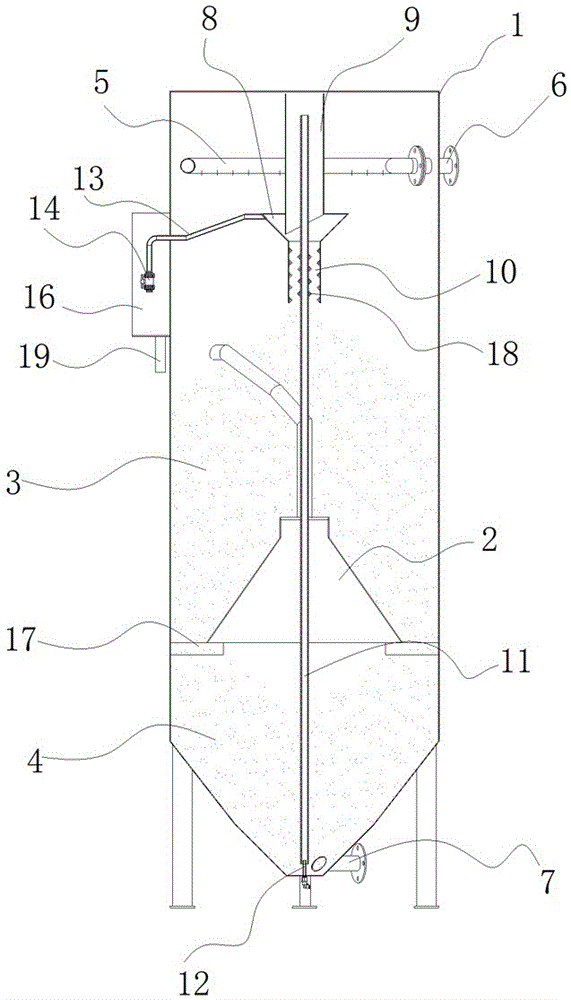

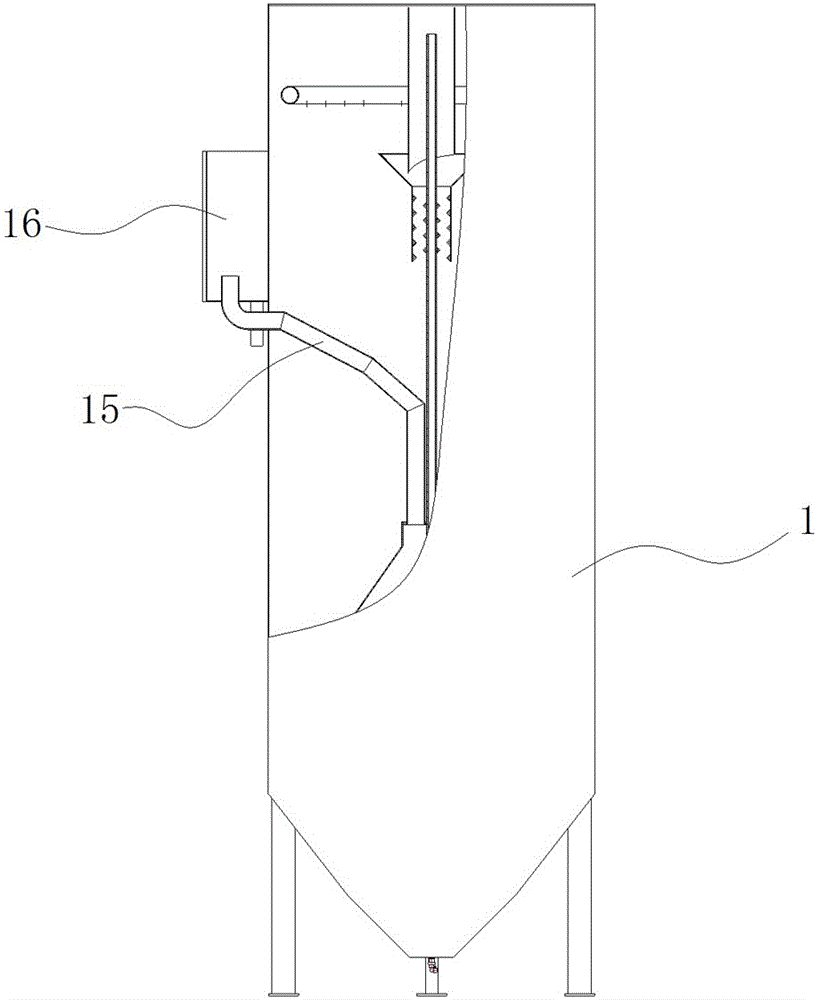

[0051] Embodiment 1: as figure 1 and figure 2 As shown, a downward flow continuous sand filter includes a filter bucket 1, a sand distribution device 2 is provided in the filter bucket 1, and a sand filter chamber 3 is provided at the upper end of the sand distribution device 2. The lower end of the sand distribution device 2 is provided with a sand chamber 4 to be cleaned, and the sand filter chamber 3 is provided with a sand filter backwash assembly and a clean water output assembly;

[0052] The upper end of the filter bucket 1 is provided with a water distribution pipe 5, and the water distribution pipe 5 communicates with the water inlet pipe 6;

[0053] The bottom end of the filter barrel 1 is provided with a sand discharge pipe 7;

[0054] The sand filter backwash assembly includes a sand washer 8, the upper end of the sand washer 8 is provided with an upper circular pipe 9, and the bottom end of the sand washer 8 is provided with a lower circular pipe 10, the The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com