Tension adjusting device of automatic paper splicing machine

A tension adjustment device and paper splicing machine technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., can solve the problems of complex structure, high accuracy and high cost of tension adjustment devices, and achieve short response time, Low production cost and constant tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

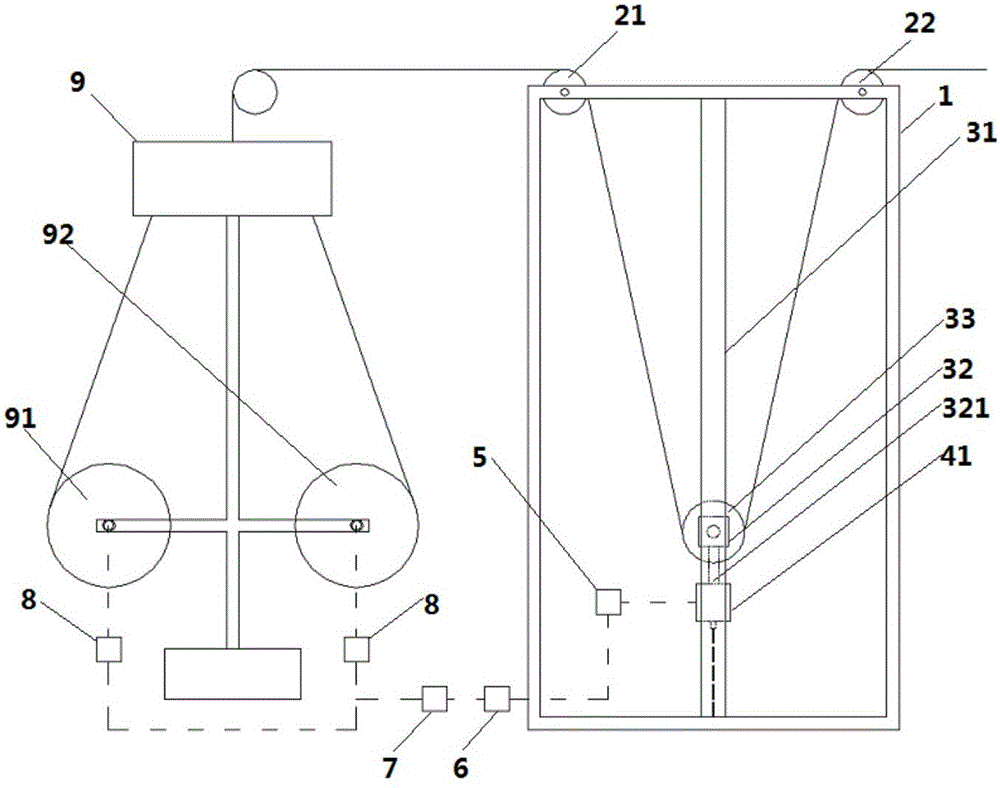

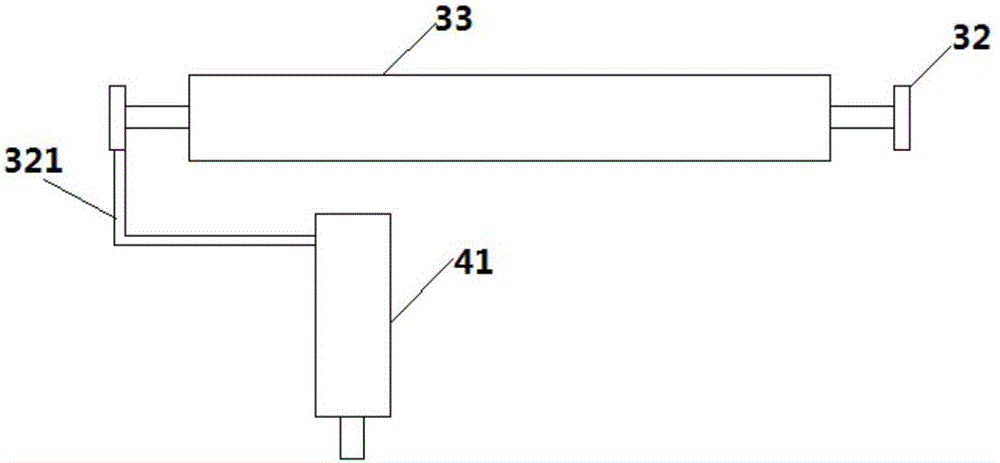

[0015] A tension adjustment device for an automatic paper splicer, such as figure 1 , 2 As shown, it includes frame 1, guide roller 2, floating roller 3, position detector 4, terminal controller 5, proportional flow valve 6, electromagnetic reversing valve 7, brake control air valve 8, and the frame 1 is located at On the paper output side of the automatic paper splicer 9, the first guide roller 21 and the second guide roller 22 parallel to the unwinding roller 91 on the automatic paper splicer 9 are arranged on the frame 1, and the floating roller 3 is arranged on the first guide roller 21 and the middle of the second guide roller 22, the position detector 4 is arranged on the floating roller 3, and the position detector 4 is a laser distance measuring sensor 41, and the laser distance measuring sensor 41 senses the height change feedback of the floating roller 3 Analyze and calculate the terminal controller 5, and the terminal controller 5 sends an electric signal to contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com