Double-position adjustable robot palletizer clamp

A robot fixture and code adjustment technology, which is applied in the field of box and bag palletizing devices and double-position adjustable palletizing robot fixtures, can solve problems such as single function, slow speed, and affecting the speed of palletizing robots, so as to improve the utilization rate , reduced investment, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

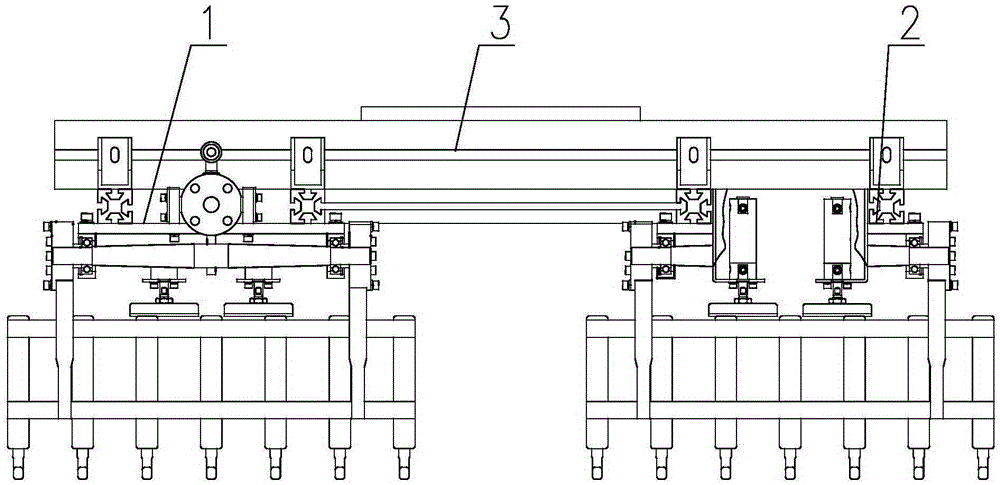

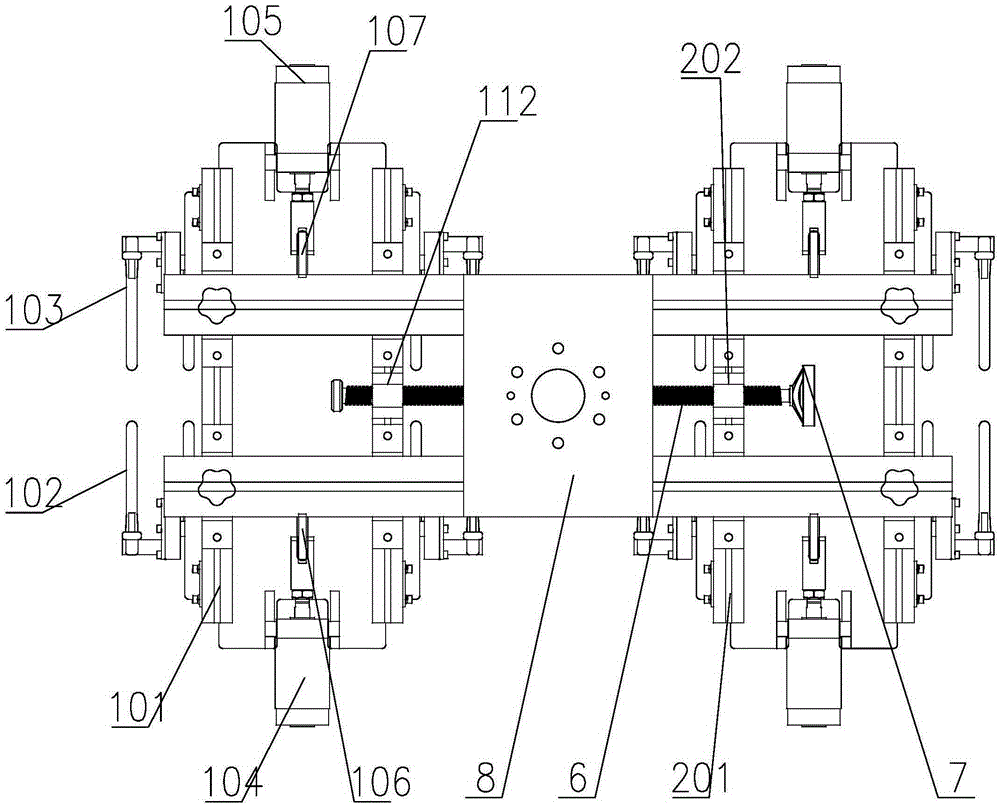

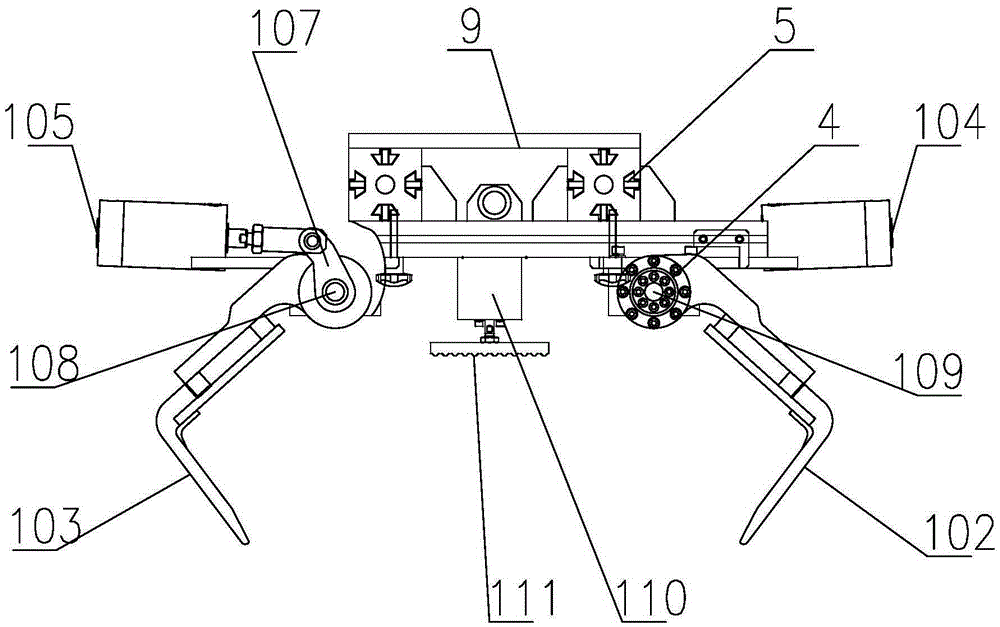

[0015] Figure 1~5 , including the first gripper 1, the first grabbing tooth cross frame 101, the first grabbing tooth assembly 102, the second grabbing tooth assembly 103, the first grabbing cylinder 104, the second grabbing cylinder 105, and the first rocker lever 106 , the second rocker lever 107, the second rocker shaft 108, the first rocker shaft 109, the pressure bag cylinder 110, the anti-slip pressure plate 111, the left-handed screw nut 112, the second clamp 2, the second gripping tooth horizontal frame 201, Right-hand screw nut 202, slider guide groove parallel frame 3, expansion sleeve 4, adjustment slider 5, screw rod 6, adjustment handwheel 7, locking handle 8, palletizing connecting plate 9, palletizing robot 10, materials 11 etc.

[0016] like Figure 1~5 As shown, the present invention is a double-position adjustable palle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com