Hydraulic system of blast furnace gun

A technology of hydraulic system and mud gun, applied in the field of blast furnace mud gun hydraulic system, can solve the problems of personnel and property safety threats, the blast furnace tap hole cannot be safely blocked, and the normal operation of the mud gun is affected, and the service life is improved. , the effect of reducing replacement frequency and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

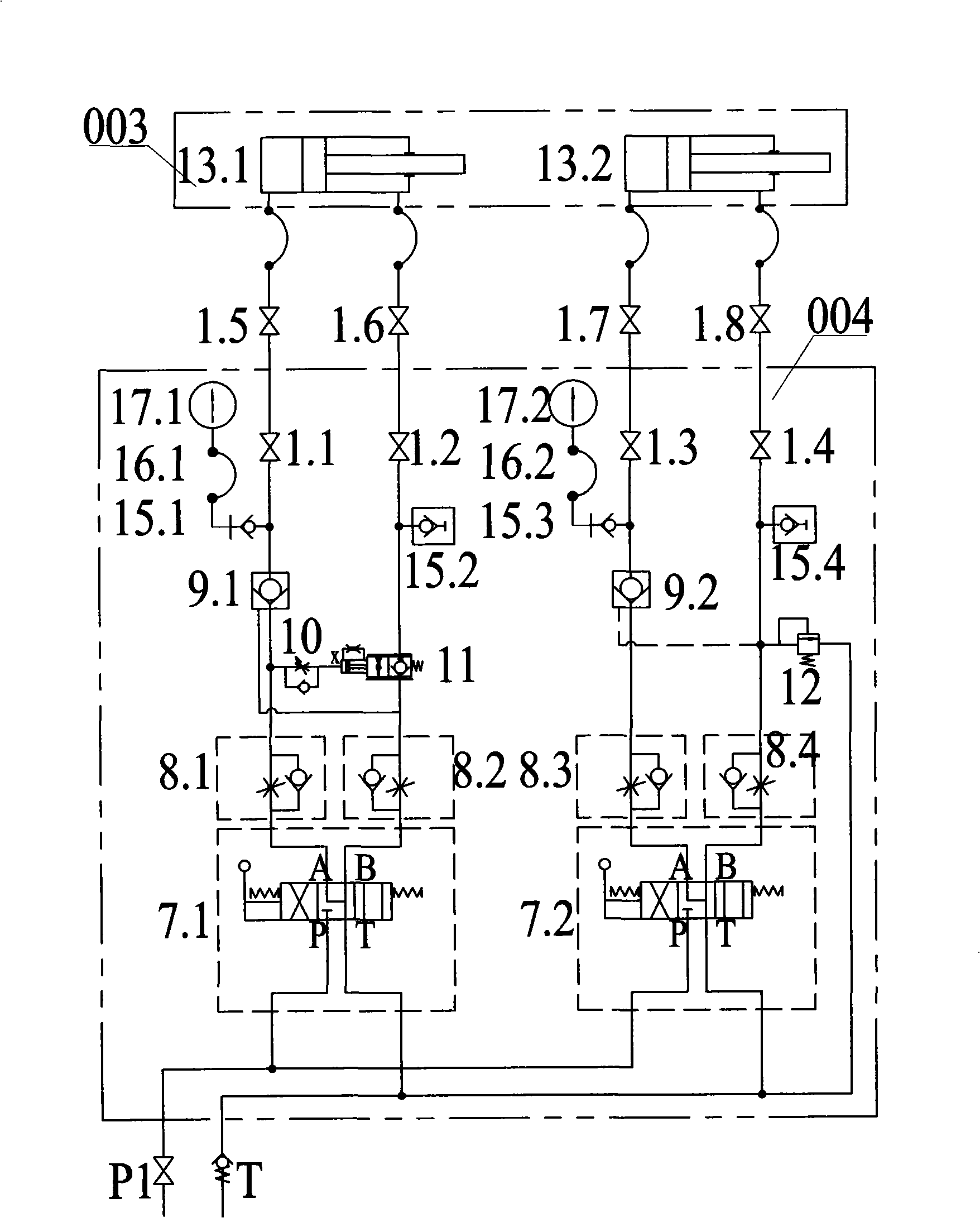

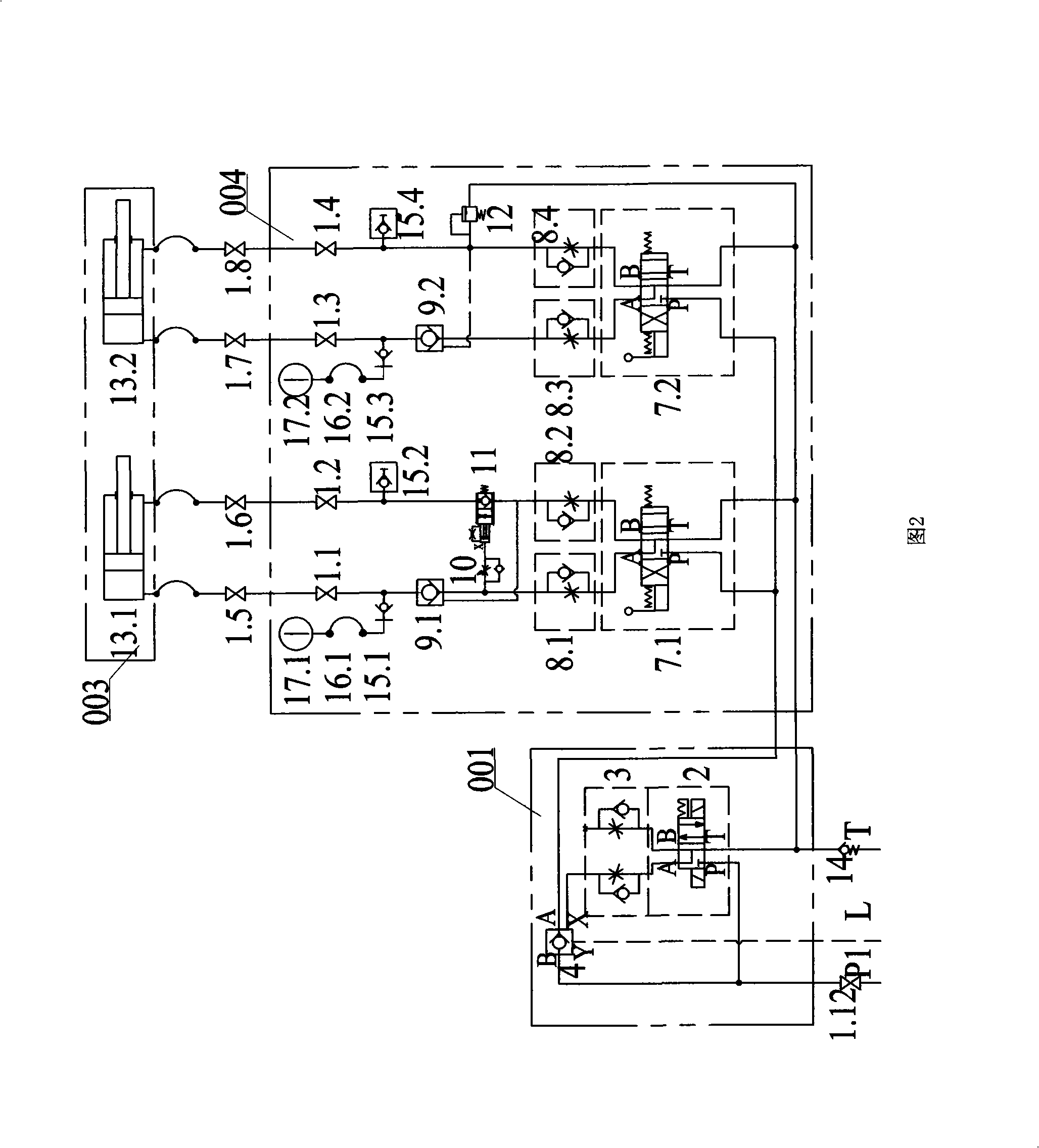

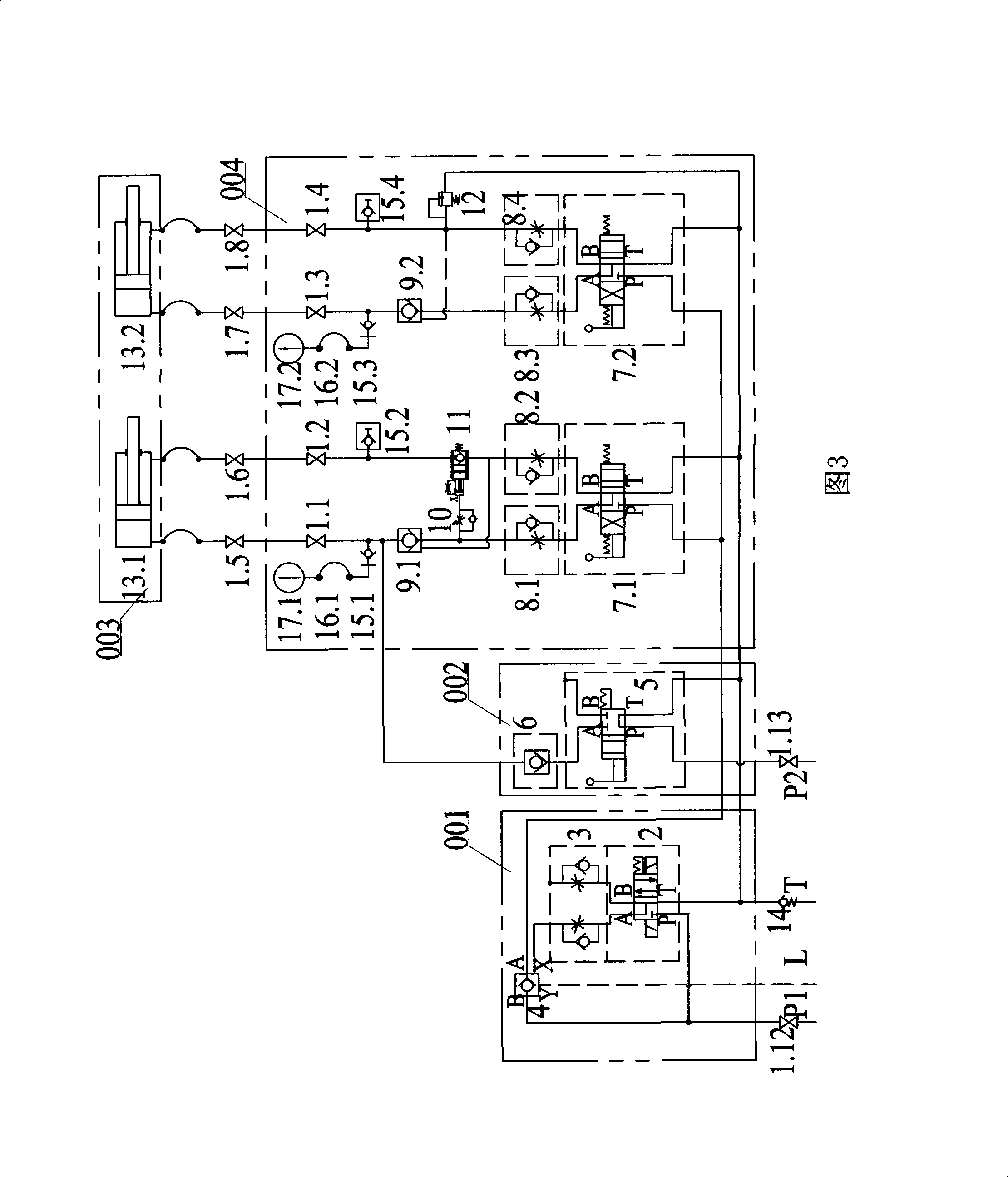

[0022] Referring to Fig. 3, a blast furnace mud cannon hydraulic system includes a safety control circuit 001, a hydraulic cylinder assembly 003 and a hydraulic cylinder control circuit 004, the safety control circuit 001 is connected to the hydraulic cylinder control circuit 004 through a hydraulic pipeline, and the hydraulic cylinder control circuit 004 It is connected with the hydraulic cylinder assembly 003 through the hydraulic pipeline, and the hydraulic system of the blast furnace mud gun also includes a pressure maintaining circuit 002. The oil supply pipe of the circuit 002 communicates with the oil source of the quantitative pump, and the oil return pipe of the pressure maintaining circuit 002 communicates with the oil return pipe of the system; the pressure maintaining circuit 002 includes an unloading reversing valve 5 and a first check valve 6. The first oil outlet A of the reversing valve 5 is connected with the oil inlet of the first one-way valve 6, and the seco...

Embodiment 2

[0028] Referring to Figure 3 and Figure 4, a blast furnace mud cannon hydraulic system includes a safety control circuit 001, a hydraulic cylinder assembly 003 and a hydraulic cylinder control circuit 004, the safety control circuit 001 is connected to the hydraulic cylinder control circuit 004 through a hydraulic pipeline, and the hydraulic cylinder The control circuit 004 is connected with the hydraulic cylinder assembly 003 through the hydraulic pipeline. The hydraulic system of the blast furnace mud gun also includes the pressure maintaining circuit 002. The pressure maintaining circuit 002 communicates with the rotary cylinder 13.1 through the hydraulic pipeline, the first ball valve 1.1 and the fifth ball valve 1.5 , the oil supply pipe of the pressure maintaining circuit 002 communicates with the quantitative pump oil source, and the oil return pipe of the pressure maintaining circuit 002 communicates with the system oil return pipe; the pressure maintaining circuit 002 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com