Bagged cement or fly ash unpacking and conveying system and operation method thereof

A conveying system and fly ash technology, used in conveyors, conveying bulk materials, packaging, etc., can solve the problems of unpacking and continuous operation of conveying systems, endangering human health, polluting the surrounding environment, etc., to ensure reliable Operation, avoid pollution, improve the effect of working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

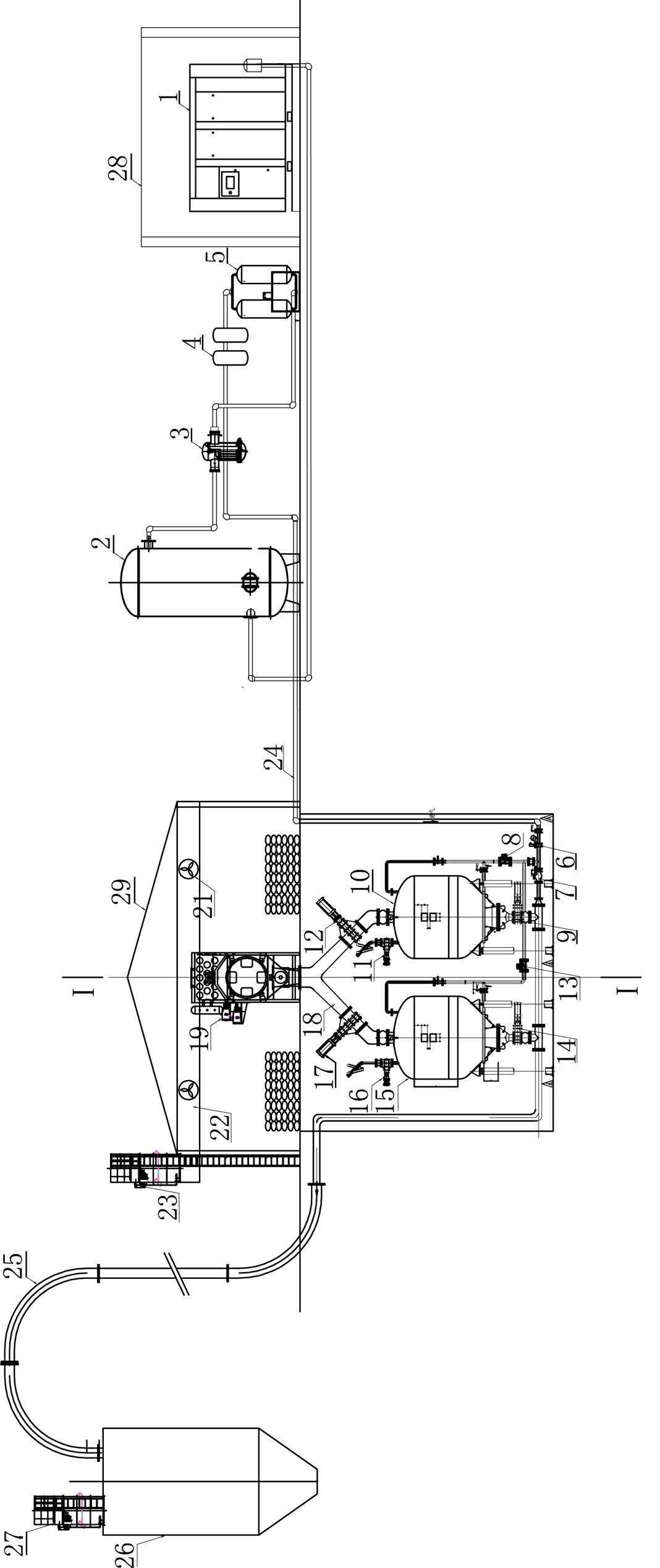

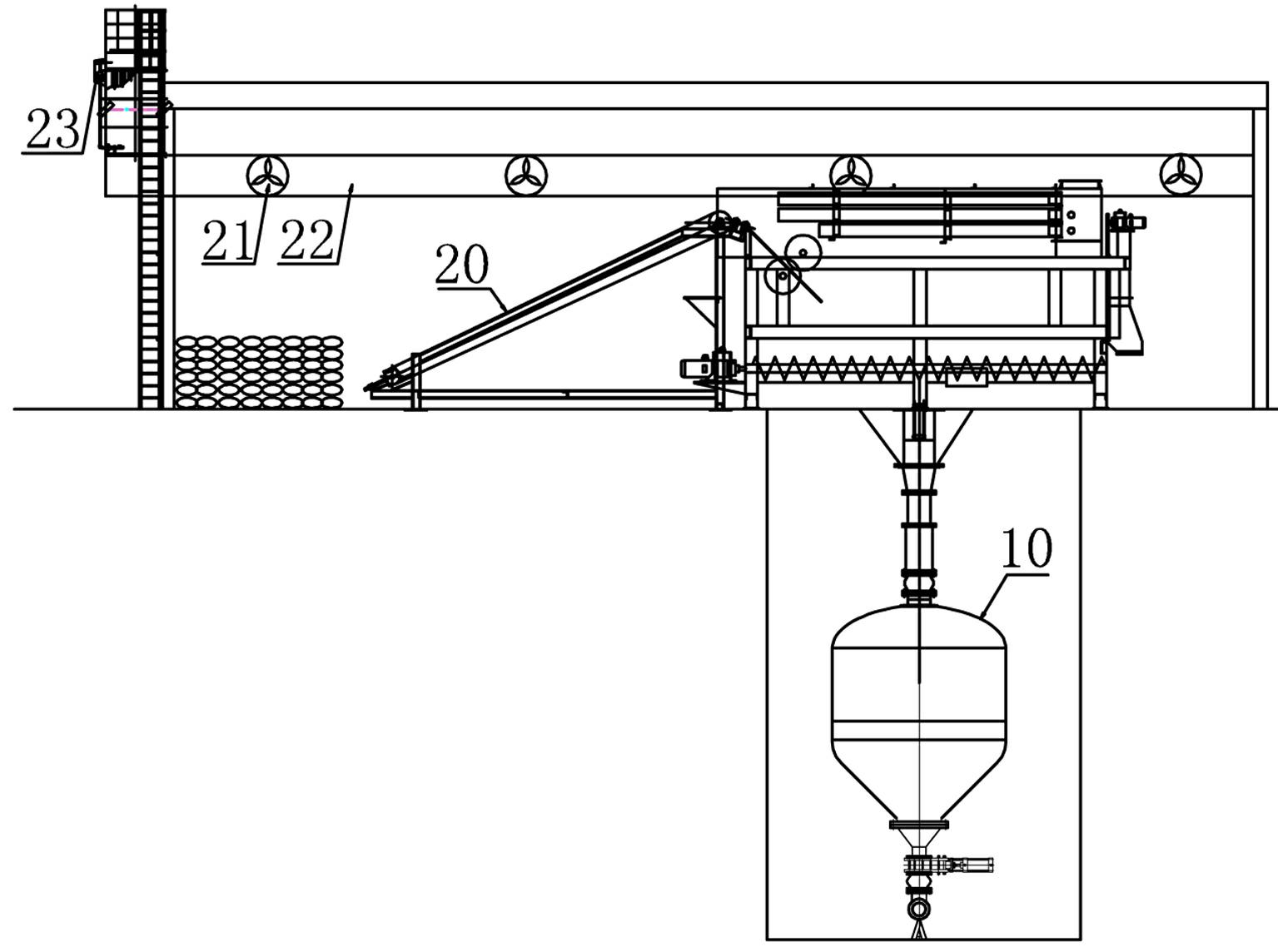

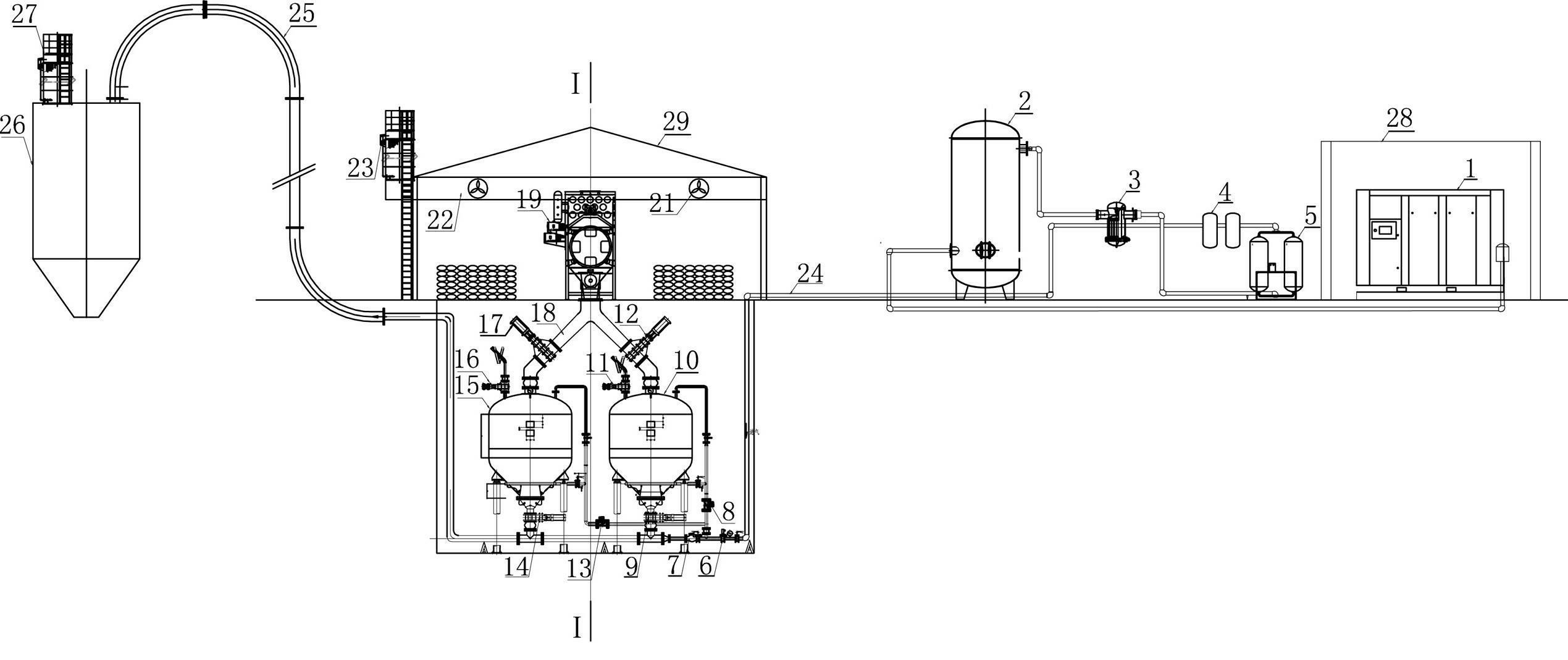

[0028] see Figure 1-2 , a bagged cement or fly ash unpacking conveying system, which includes an air compressor 1, the air compressor is connected to an air storage tank 2 through a pipeline, and the air storage tank is connected to a dryer 5 through a pipeline, and the dryer and the air storage tank There is a first filter 3 between them, a second filter 4 is set between the dryer and the vertical warehouse pump, the dryer is connected to the vertical warehouse pumps 10 and 15 through pipelines, and a discharge valve is provided at the bottom of the vertical warehouse pump 9, 14, the lower end of the discharge valve is connected to the storage tank 26 through the feed pipe 25, the upper part of the vertical warehouse pump is provided with an exhaust port and a feed pipe 18, and the exhaust port is provided with an exhaust valve 11, 16, and the feed pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com