Wind-uniformizing plate

A technology of air equalizing plate and plate body, which is applied in the direction of solid separation, chemical instruments and methods, electrostatic effect separation, etc., and can solve the problems of electrostatic dust removal unit failure and air equalizing effect, so as to ensure continuous normal operation, improve work efficiency, and achieve good uniformity The effect of entering the wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention provides an air equalizing plate. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

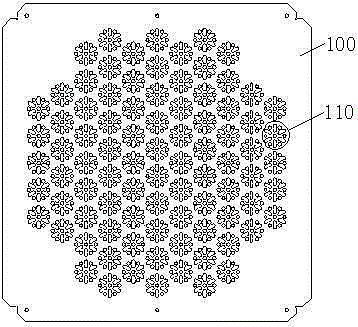

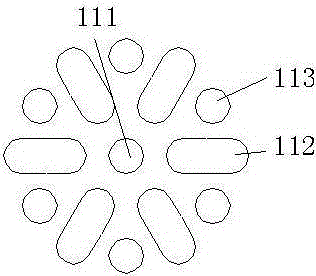

[0018] Such as figure 1 and image 3 An air equalizing plate is shown, which includes a plate body 100 and a through hole array 110 arranged on the plate body 100, wherein each through hole array corresponds to an anode cylinder in the electrostatic precipitator unit. The air equalizing plate of the present invention is installed before the electrostatic precipitator unit to evenly distribute the flue gas entering the electrostatic precipitator unit, so as to ensure the normal operation of the electrostatic precipitator unit and ensure the dust removal effect. The through hole array on the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com