Machine for recycling mulch film during seedling stage

A recycling machine and mulching technology, applied in collectors, agricultural machinery and tools, applications, etc., can solve problems affecting crop growth and development, reducing crop yield, affecting mechanical operations, etc., to facilitate recycling, reduce pollution, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

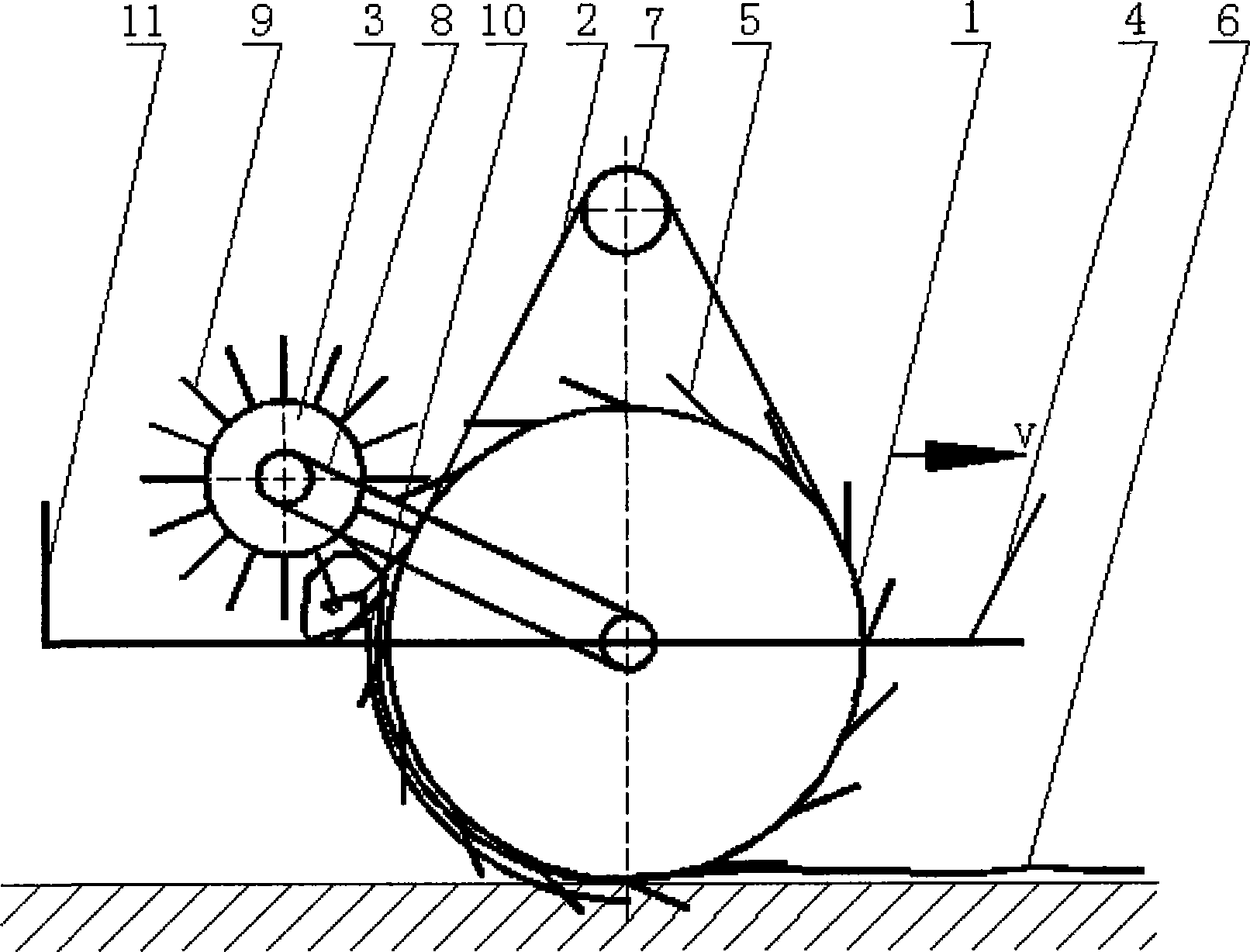

[0012] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0013] like figure 1 As shown, the present invention includes a film lifter 1, a film blocking film unloading flat belt 2 and a film unloading wheel 3. The film lifter 1 is designed as a wheel and is fixedly installed on the frame 4 on both sides of the crop seedling. The outer ring of the film lifter 1 is provided with a plurality of film pick-up teeth 5 in the circumferential direction, and each film pick-up tooth 5 has the same inclination angle design. The film pulling wheel 1 is a non-driving wheel, and the pulling mechanism connected with the frame 4 drives the film pulling wheel 1 to move forward. The film pulling wheel 1 is in contact with the ground, and the film pulling wheel 1 rotates under the action of ground friction. The upper film-lifting teeth 5 lift up the mulch film 6 .

[0014] In order to prevent the film 6 from being entangled by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com