Bidirectional floating adapter and adapting contact assembly thereof

A technology of floating contacts and contacts, which is applied to the parts, connections, electrical components, etc. of the connection device, which can solve the problem of limited precision and difficulty in mating the adapter and the corresponding connector, and the adapter and the corresponding connector For problems such as plugging failure, to achieve a good contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

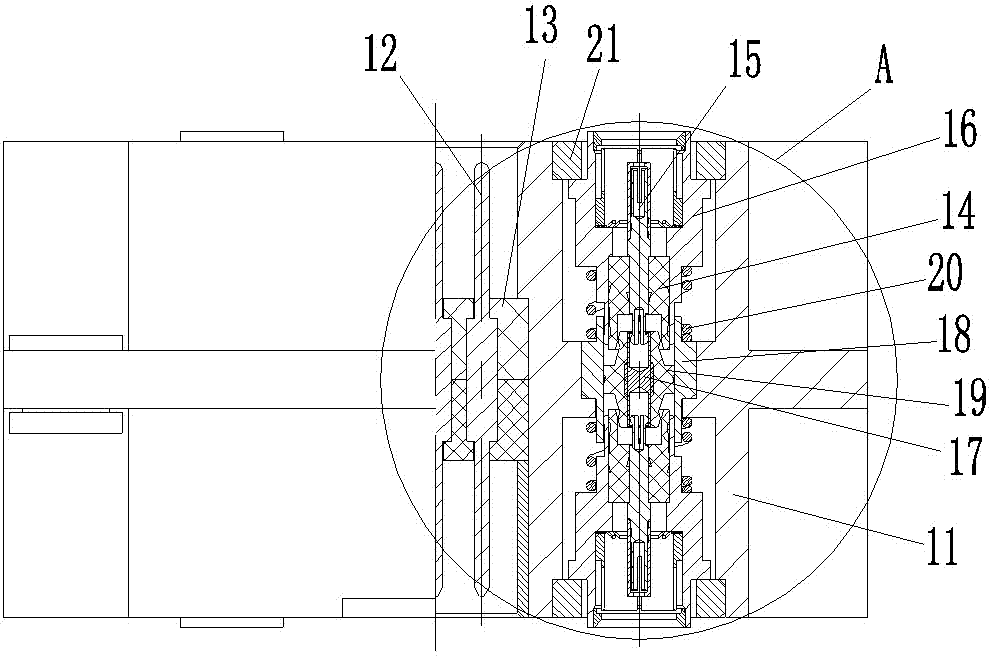

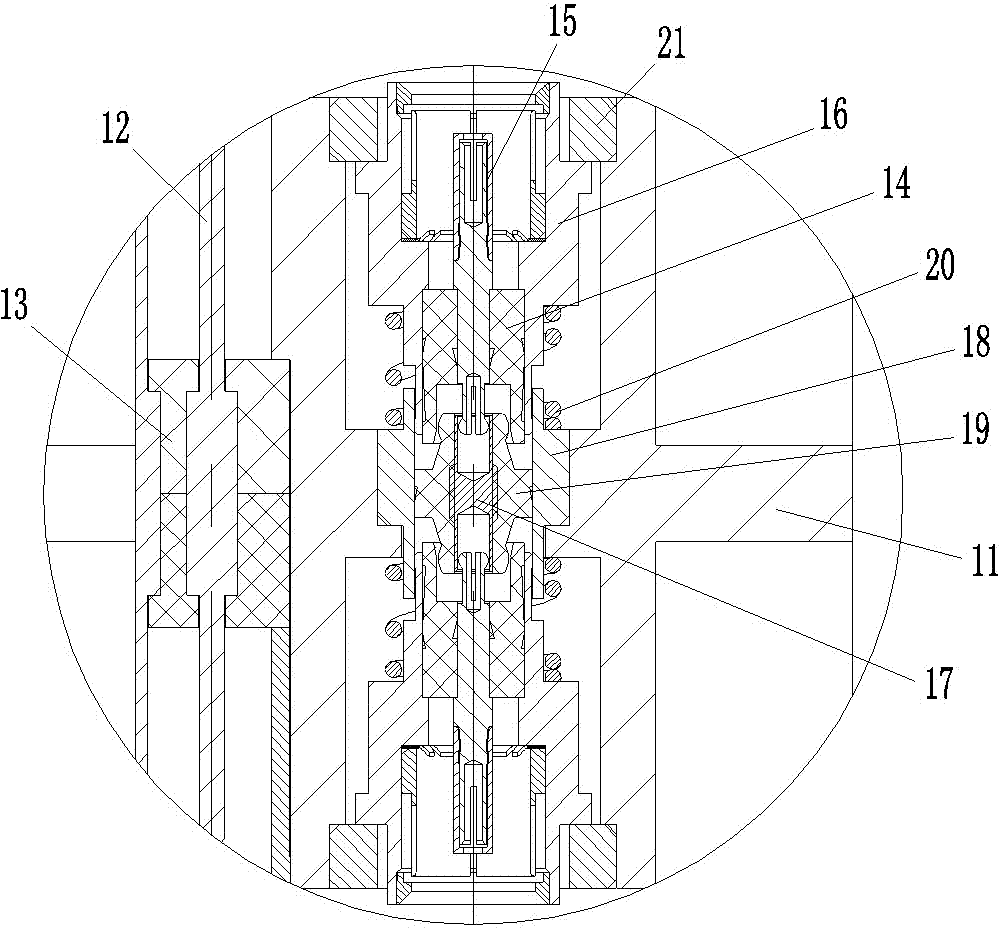

[0020] Examples of bidirectional floating adapters, such as Figure 1-2 , a two-way floating adapter, including a housing 11 and a transfer contact assembly.

[0021] Housing 11 is provided with mounting holes. In this embodiment, the two-way floating adapter is a high-low frequency mixed adapter, so the mounting holes on the housing are divided into high-frequency transfer contact mounting holes and low-frequency contact mounting holes.

[0022] As mentioned above, the two-way floating adapter is a high-low frequency mixed adapter, wherein the low-frequency transfer contact 12 is a pin contact, which is fixedly assembled in the low-frequency installation hole through the low-frequency insulator 13, and the low-frequency transfer contact The structure and assembly method of the component 12 are prior art, and will not be repeated here.

[0023] The transfer contact assembly mentioned above is equivalent to a high-frequency contact. In this embodiment, the transfer contact as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com