An electric machine and a method for adjusting the axial bearing clearance

An axial bearing and bearing technology, which is used in the manufacture of motor generators, casings/covers/supports, electrical components, etc., can solve the problem of time-consuming adjustment of axial clearances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

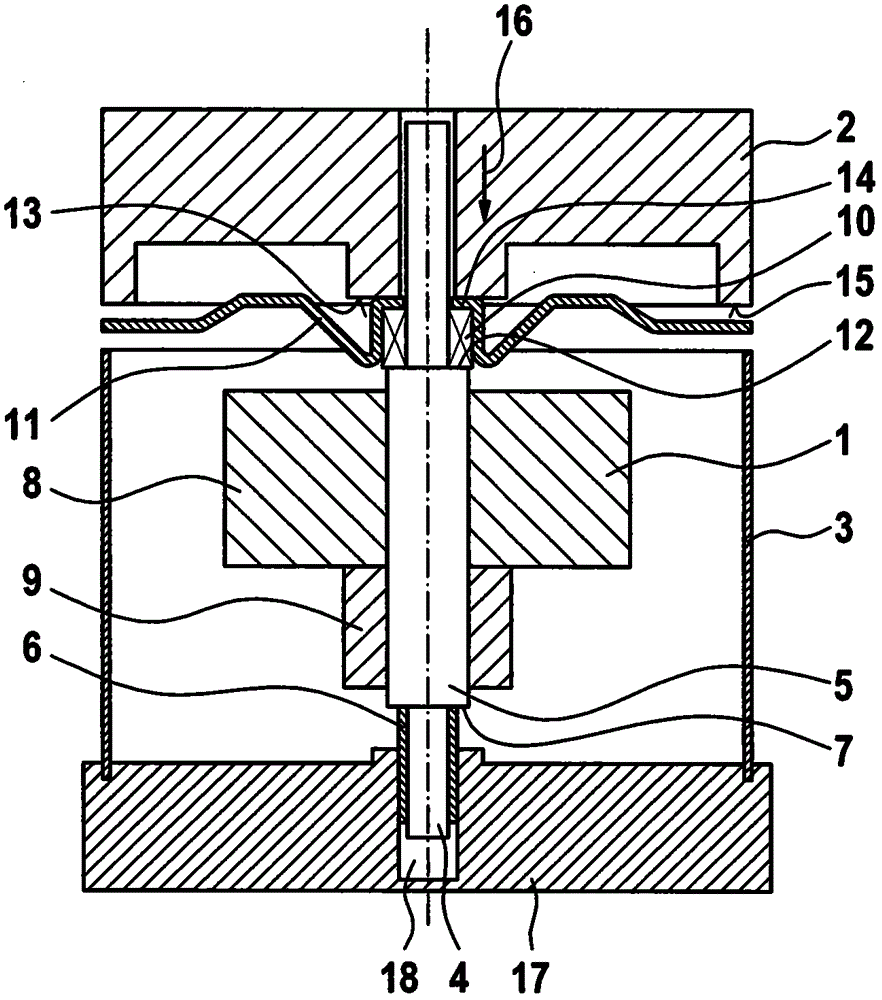

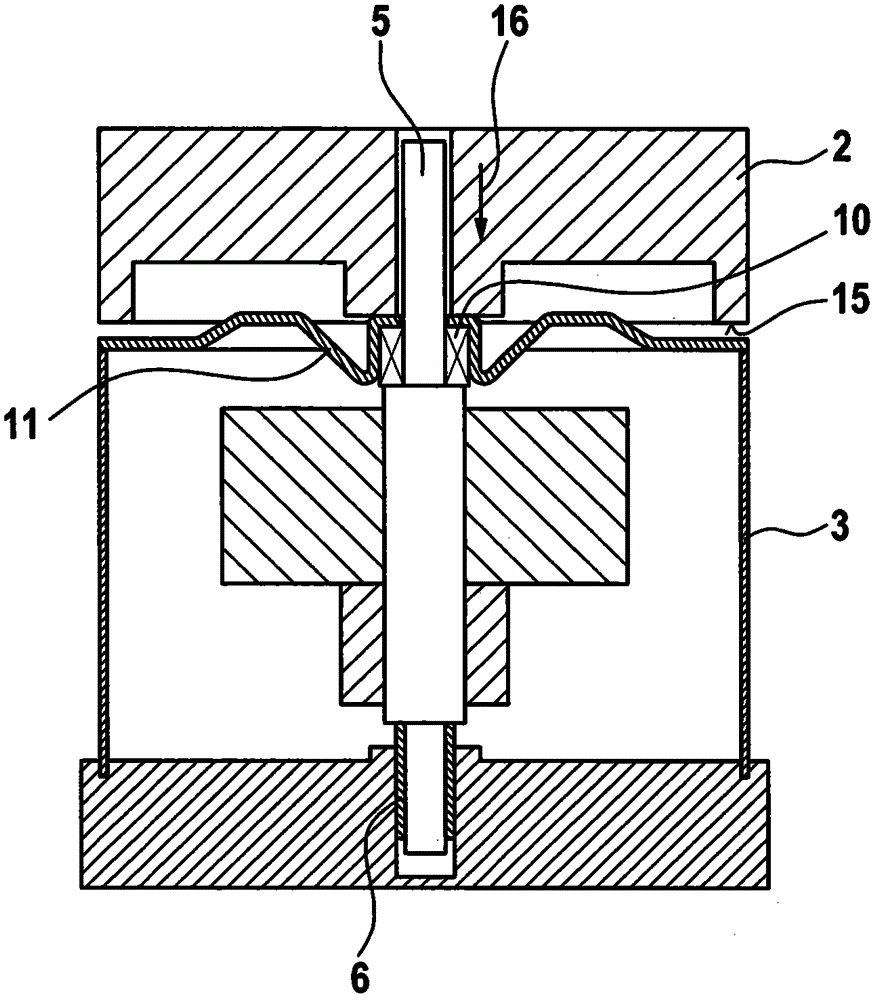

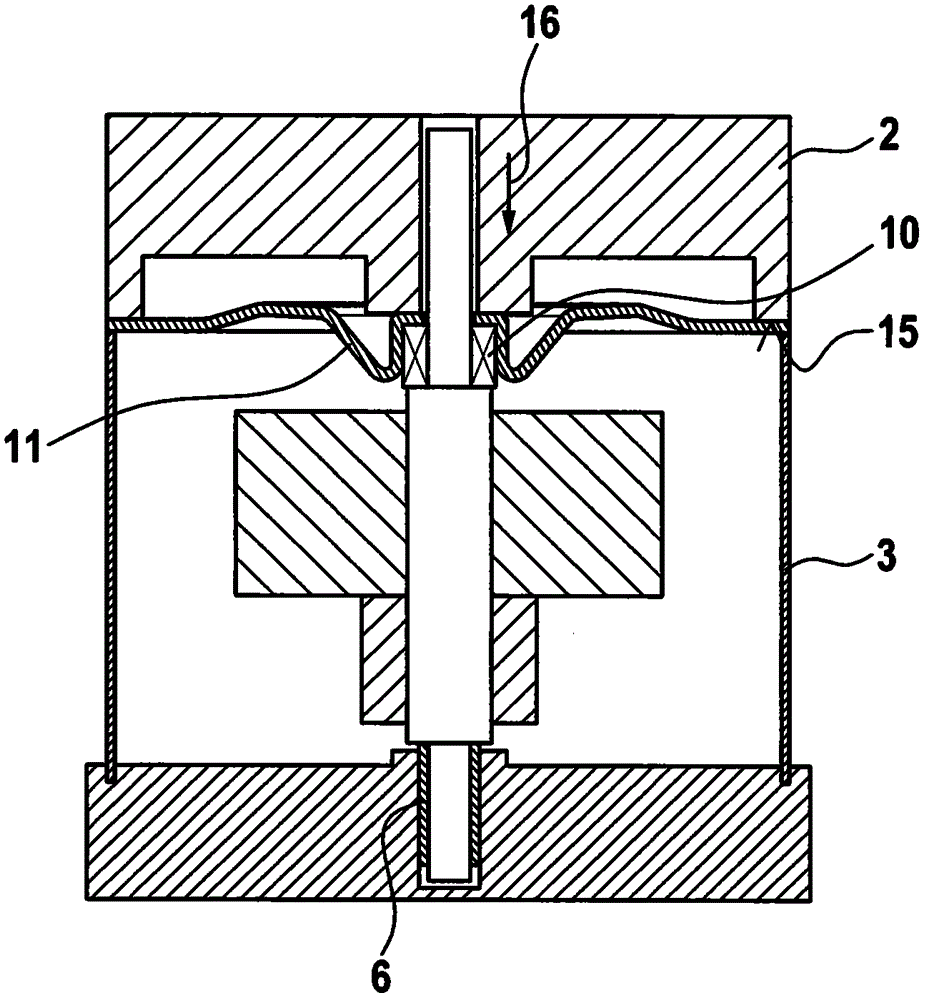

[0020] figure 1 An electric machine is shown in a very simplified cross-sectional view in which a rotor 1 is inserted into a housing 3 of the electric machine by means of an assembly tool 2 . The rotor 1 and the assembly tool 2 are located in a first assembly step in which the rotor 1 is placed with the lower end 4 of the rotor shaft 5 in a first movable bearing 6 . The rotor shaft 5 bears against the first displaceable bearing 6 with an annular shoulder 7 . Located on the other side of the rotor 1 with the armature 8 and the commutator 9 is a second bearing 10 which is inserted into an axially elastic bearing seat 11 . The second bearing 10 likewise bears against a shoulder 12 of the rotor shaft 5 .

[0021] The bearing support 11 is designed as a rotationally symmetrical sheet metal cover and has an approximately wave-like contour in cross section, which imparts the required axial elasticity to the bearing support 11 .

[0022] On the bearing support 11 , a bearing socket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com