Solvent-free two-component polyurethane laminating adhesive and preparation method thereof

A two-component polyurethane, solvent-free technology, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve packaging bag air leakage, wrinkling of heat-sealed edges, insufficient heat resistance of colloids, etc. problem, to achieve the effect of no VOC emission, environmental friendliness and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

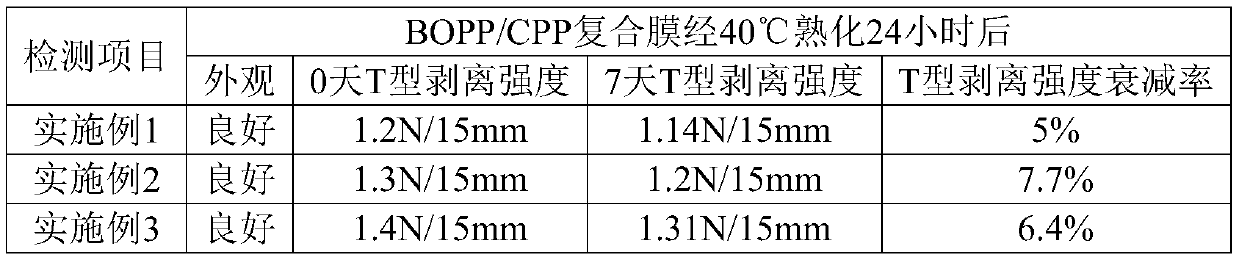

Examples

Embodiment 1

[0027] Preparation of component A: 25Kg of 2,4'-diphenylmethane diisocyanate and 25Kg of 4,4'-diphenylmethane diisocyanate and 4Kg of carbodiimide-modified 4,4'-diphenyl Methyl methane diisocyanate and 20Kg of polyether diol with an average molecular weight of 1000 and 26Kg of polyether diol with an average molecular weight of 2000 were evenly mixed, then heated up to 85°C and kept for 2.5 hours to obtain an NCO mass fraction of 15 % - 15.5% of Component A.

[0028] The preparation of polyester diol with an average molecular weight of 500: 45Kg of adipic acid, 15Kg of 2-methyl 1,3-propanediol and 40Kg of diethylene glycol were added to the polyester kettle, stirred evenly, Continue to add 0.5Kg of triphenyl phosphite as an antioxidant and 0.05Kg of tetra-n-butyl titanate as a catalyst. After esterification and polycondensation, the average molecular weight of hydroxyl value between 210-220mgKOH / g is 500 of polyester diols.

[0029] Preparation of component B: 55Kg of polyeth...

Embodiment 2

[0032] Preparation of component A: 26Kg of 2,4'-diphenylmethane diisocyanate and 26Kg of 4,4'-diphenylmethane diisocyanate and 20Kg of polyether diol with an average molecular weight of 1000 and 28Kg of After the polyether diols with an average molecular weight of 2000 are mixed evenly, the temperature is raised to 8° C. and the reaction is kept for 3 hours to obtain component A with an NCO mass fraction of 15%-15.5%.

[0033] The average molecular weight is the preparation of the polyester diol of 500: the adipic acid of 38Kg, the isophthalic acid of 8Kg, the 2-methyl 1 of 36Kg diethylene glycol and 18Kg 1,3-propanediol are added to poly In the ester kettle, stir evenly, continue to add 0.5Kg of triphenyl phosphite as an antioxidant, and 0.03Kg of tetra-n-butyl titanate as a catalyst. After esterification and polycondensation, the hydroxyl value is 210-220mgKOH / g Polyester diols with an average molecular weight of 500.

[0034] Preparation of component B: Mix 60Kg of polyeth...

Embodiment 3

[0037] Preparation of component A: 26Kg of 2,4'-diphenylmethane diisocyanate, 26Kg of 4,4'-diphenylmethane diisocyanate and 6Kg of carbodiimide-modified 4,4'-diphenyl Methyl methane diisocyanate and 15Kg of polyether diol with an average molecular weight of 1000 and 30Kg of polyether diol with an average molecular weight of 2000 are uniformly mixed, then heated up to 90°C and incubated for 2 hours to obtain an NCO mass fraction of 15 % - 15.5% of Component A.

[0038]The average molecular weight is the preparation of the polyester diol of 500: the adipic acid of 38Kg, the isophthalic acid of 8Kg, the 2-methyl 1,3-propanediol of the diethylene glycol of 38Kg and 16Kg are added to poly In the ester kettle, stir evenly, continue to add 0.5Kg of triphenyl phosphite as an antioxidant, and 0.04Kg of tetra-n-butyl titanate as a catalyst. After esterification and polycondensation, the hydroxyl value is 210-220mgKOH / g Polyester diols with an average molecular weight of 500.

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com