Hot melt adhesive coating device and coating method for composite smooth aluminum sheathed high-voltage cables

A coating device and hot-melt adhesive technology, applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problems of crushing the inner insulation layer of the cable, bowing of the sheath, and hazards to the safe operation of the cable, so as to avoid local Discharge, ensure the appearance quality, and the effect of uniform electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

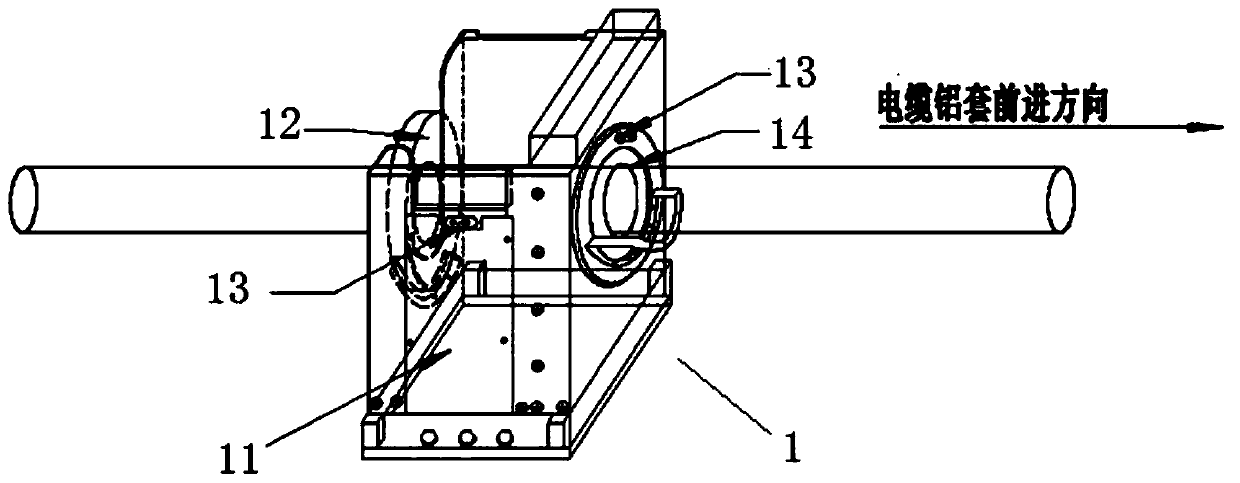

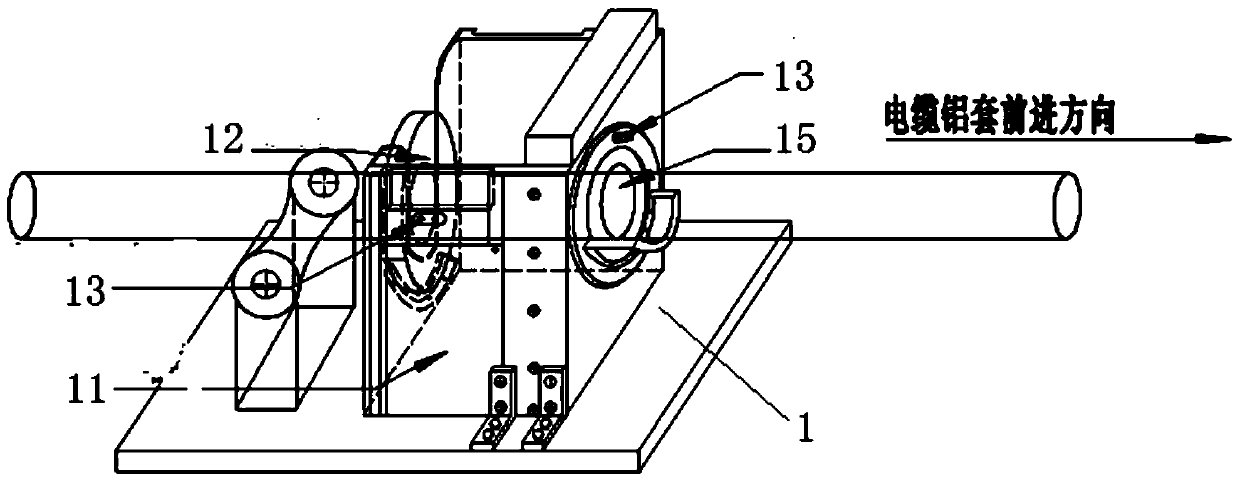

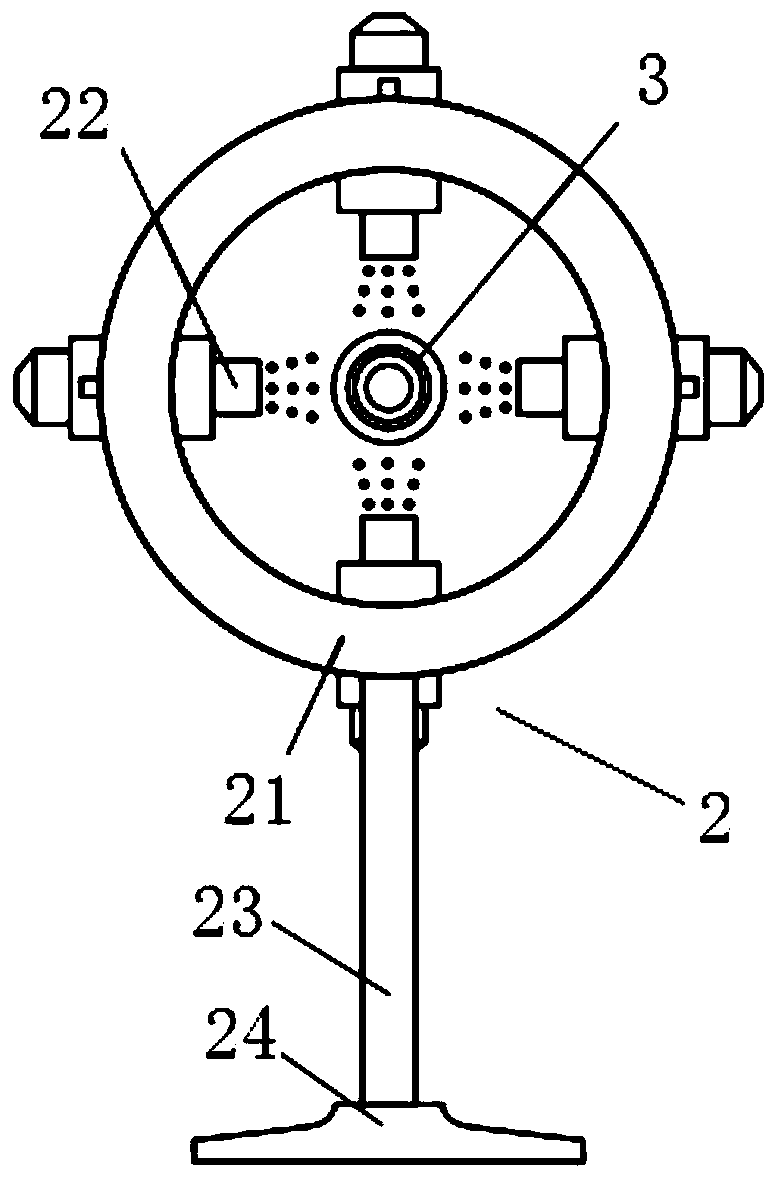

[0030] Such as figure 1 with figure 2 As shown, a composite smooth aluminum sheathed high-voltage cable hot melt adhesive coating device includes an argon arc welding production line and an extruder. The argon arc welding production line includes a welding torch part and a traction part, and also includes two hot melt adhesive coating Device 1, namely:

[0031] The first hot-melt adhesive coating device is arranged between the welding torch part and the pulling part, including a hot-melt adhesive tank 11, a glue-resisting mold 12, a drawing mold 14, an electric heating temperature control assembly 13, and the glue-resisting mold and the drawing The draft is set on the two opposite side walls of the hot melt adhesive tank, the hot melt adhesive tank is filled with hot melt adhesive particles, heated by the electric heating temperature control component to make the hot melt adhesive particles into liquid and completely submerge the aluminum sleeve , the aluminum sleeve enters...

Embodiment 2

[0042] A composite smooth aluminum-sheathed high-voltage cable hot-melt adhesive coating process, using a composite smooth aluminum-sheathed high-voltage cable hot-melt adhesive coating device in Example 1 for coating,

[0043] The new process flow of coating hot melt adhesive designed: wrapping the cable core of the buffer layer→→welding the aluminum sleeve→→drawing the aluminum sleeve (at the same time coating the hot melt adhesive for the first time)→→preheating the composite aluminum sleeve→→the second Secondary coating of hot melt adhesive → → double-layer co-extrusion of the conductive layer of the outer sheath → → water tank cooling → → finished product winding.

[0044] In this new process, the cable core wrapped around the buffer layer is released from the pay-off frame, and after the aluminum sleeve is welded, the hot melt adhesive is applied for the first time while entering the aluminum sleeve drawing process. These two steps are carried out at the same time. , and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com