Thin film attaching method

A sticking and thin-film technology, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as air bubbles and wrinkles, and achieve high quality and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

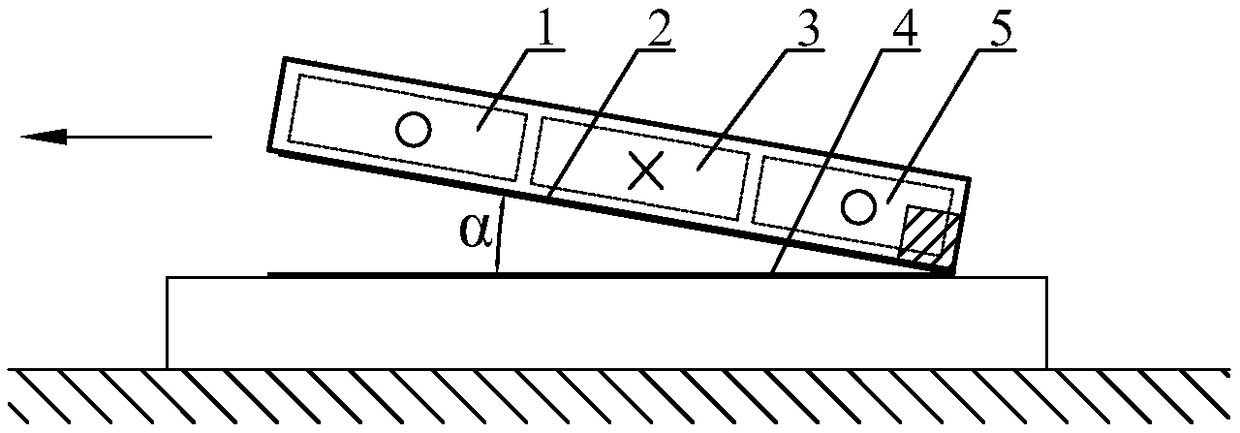

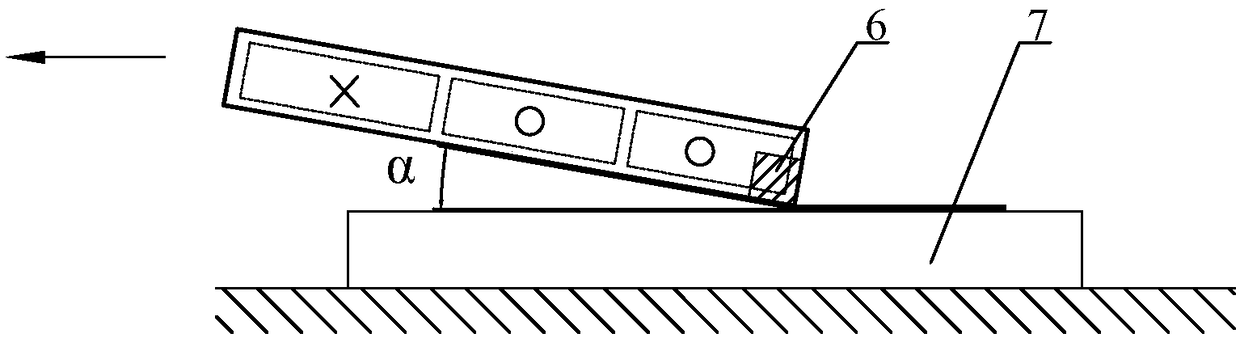

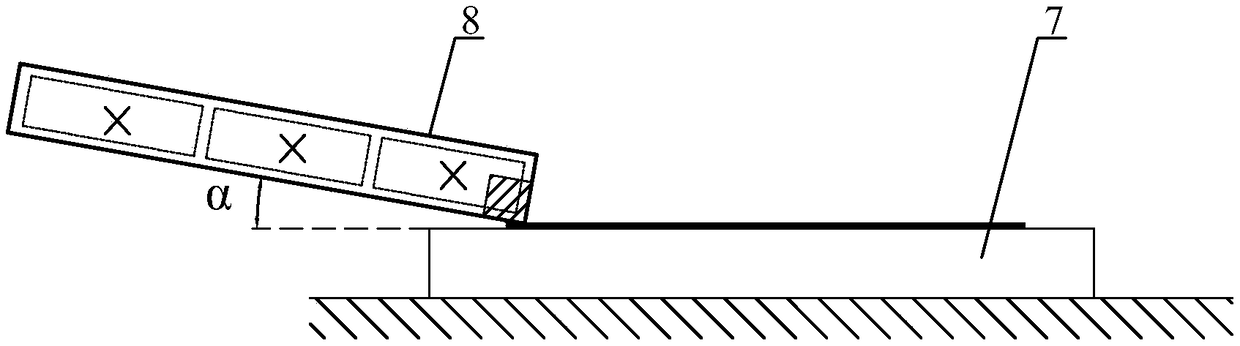

[0035] Example: see Figure 1 to image 3 , a method for attaching a film, using a film attaching device to attach a film 2 and a substrate 4 to be attached, and the film attaching device includes an attaching head 8 and an attaching table 7.

[0036] The sticking head 8 is provided with a suction surface 9, which is one side surface of the sticking head 8, and an sticking action part 6 is arranged on one side edge of the sticking face 9, and the sticking action part 6 It is a linear cutting edge 11 for sliding and laminating the film when pasting the film, or an attachment roller 12 for rolling the laminating film.

[0037] The inside of the attachment head 8 is provided with at least two mutually independent vacuum chambers, each vacuum chamber is arranged along a direction perpendicular to the linear cutting edge 11 or the axis of the attachment roller 12, and the adsorption surface 9 is provided with a plurality of suction chambers. The air holes 10, each air suction hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com