Structure for body-side outer panel and fender piece area of automobile

A technology for side wall outer panels and fenders, which is applied to the superstructure, vehicle components, superstructure sub-assemblies, etc., can solve the problems of inability to release sheet materials, high scrap rate of parts, and increased production and manufacturing costs. Achieve the effect of ensuring surface quality and matching gap, improving appearance gap and matching, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Combine below Figure 5 to Figure 9 , the present invention is further described:

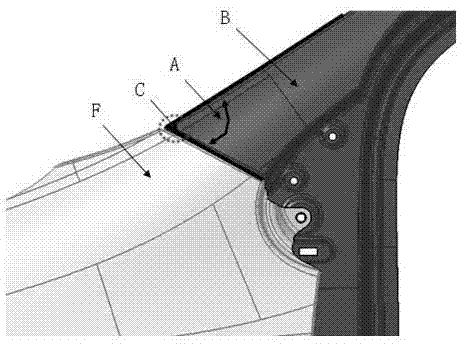

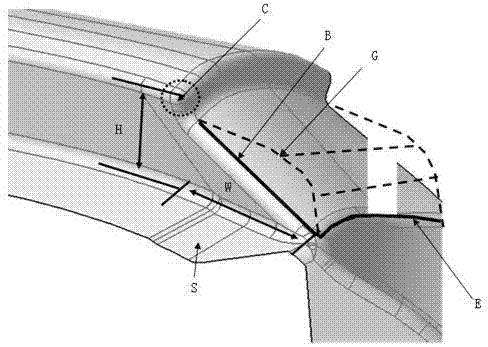

[0044] Figure 5 , the angle A between the upper seam edge of the side wall and the parting line of the fender is required to be as large as possible. When the side wall is welded and the side is shaped, the angle of the wedge should be as perpendicular as possible to the upper seam edge of the side wall. If the angle between the top edge of the side wall and the parting line of the fender is less than 80°, the corner area (C) of the side wall cannot be shaped in place, and the surface quality is poor, which will affect the surface quality of the side wall and the appearance gap when the fender is matched. . There can be an adjustment amount of about 10° during the side shaping of the wedge. Considering the shape requirements, it is recommended that the angle A between the upper lip of the side wall and the parting line of the fender be greater than 80°. During the stamping process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com