Wire arrangement control method and control system for aluminum clad steel wire coiling machine

A control method and control system technology, which is applied in the field of wire arrangement control, can solve problems such as the vacancy of the beveled side of the take-up reel, and the products cannot be neatly arranged to fill the take-up reel, etc., to achieve reasonable layout, simple and reasonable control method, and high control precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

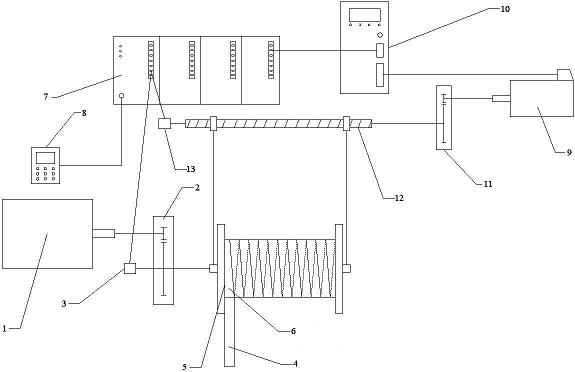

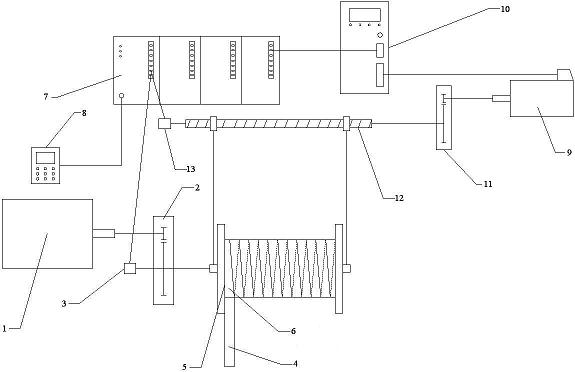

[0020] The take-up motor 1 is connected to the take-up reducer 2, and a take-up encoder 3 is installed on the take-up reducer 2. The take-up encoder 3 is used to detect the angle and speed. The take-up encoder 3 is coaxial with the top of the take-up reel Rotate, the pulse signal sent by the take-up encoder 3 is sent to PLC7, and the PLC can convert the pulse signal into the speed and rotation angle of the take-up reel through the compiled user program, and calculate the line speed, and output the analog after D / A conversion The voltage signal is sent to the frequency converter 10, and the frequency converter 10 controls the wire-arranging motor 9 to arrange the wires.

[0021] A cable encoder 13 is installed on the end of the screw 12 connected to the cable reducer 11. The cable encoder 13 is used to detect the position. The cable encoder 13 rotates coaxially with the screw 12. The output signal of the cable encoder 13 Connected to the switch input terminal of the PLC, with t...

Embodiment 2

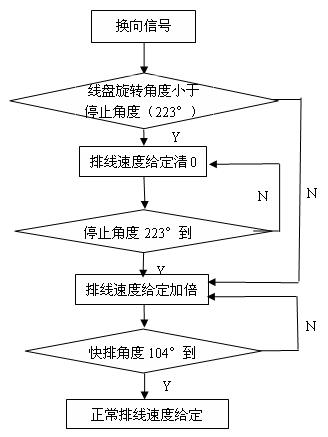

[0024] The above-mentioned control system is used to control the winding of the aluminum-clad steel wire. The specific method is: during the operation of the aluminum-clad steel wire winder, when the aluminum-clad steel wire product 4 wound up is wound on the left end surface of the take-up reel 5 (at this time The set commutation position coordinate value is equal to the actual position coordinate value, that is, the commutation signal is generated), the take-up encoder 3 starts to detect the rotation angle of the take-up reel, when the rotation angle is at the set "stop angle" (through the text When the editor sets the "stop angle" to 223°), control the speed of the wire-arraying motor 9 (variable frequency motor) to 0 to ensure that the aluminum-clad steel wire is fully filled with the hypotenuse vacancy 6 left on the boundary end face of the take-up reel; After the end faces are aligned, reverse operation. In order to ensure that the wires do not overlap after the reverse, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com