Intelligent new textile material cutting device for spinning

A new material and cutting technology, which is applied in the cutting of textile materials, textiles and paper making, etc., can solve the problems of wrinkles, the impact on the health of the staff, and reduce the practicability of the cutting device, so as to improve the cutting quality, reduce the impact, and improve the practicality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

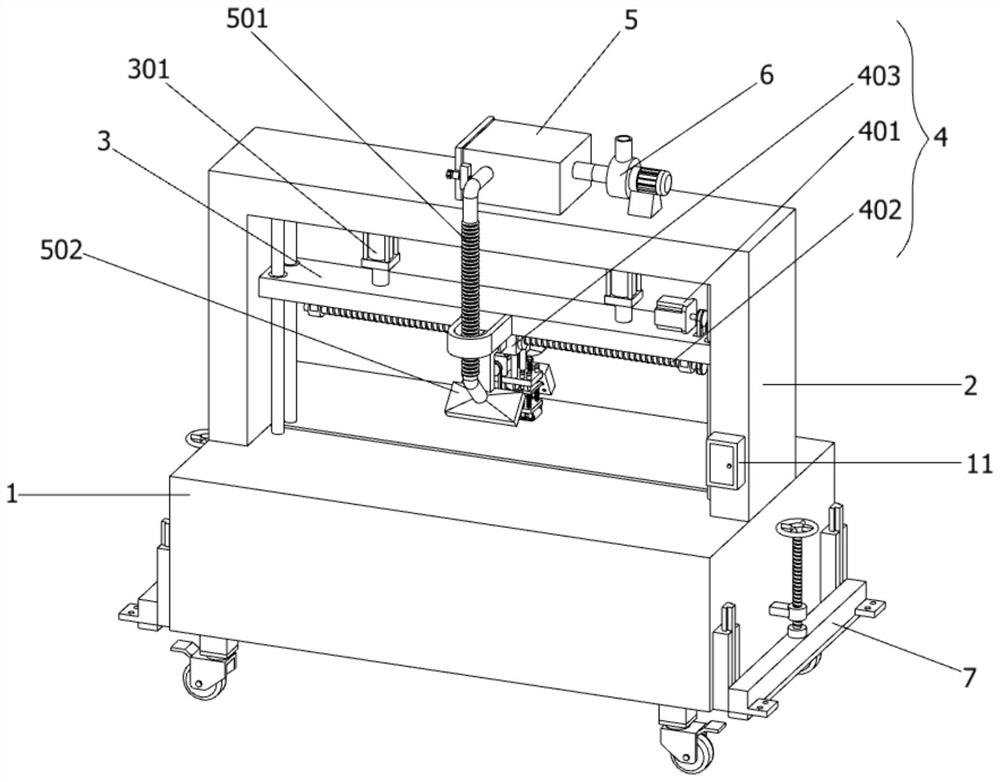

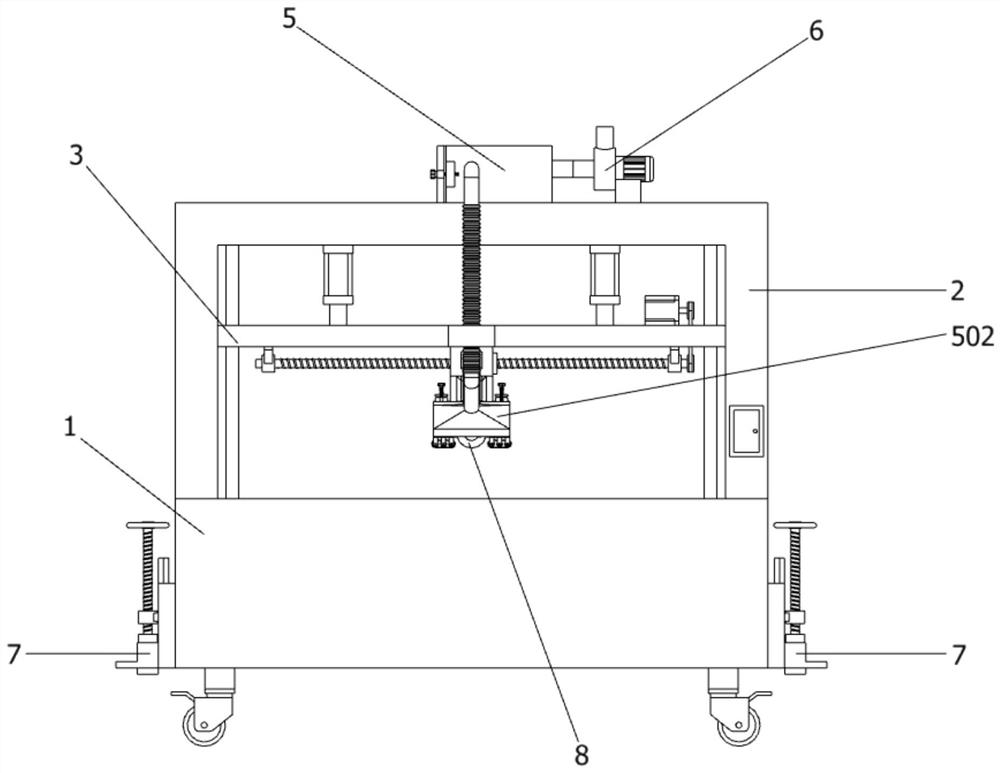

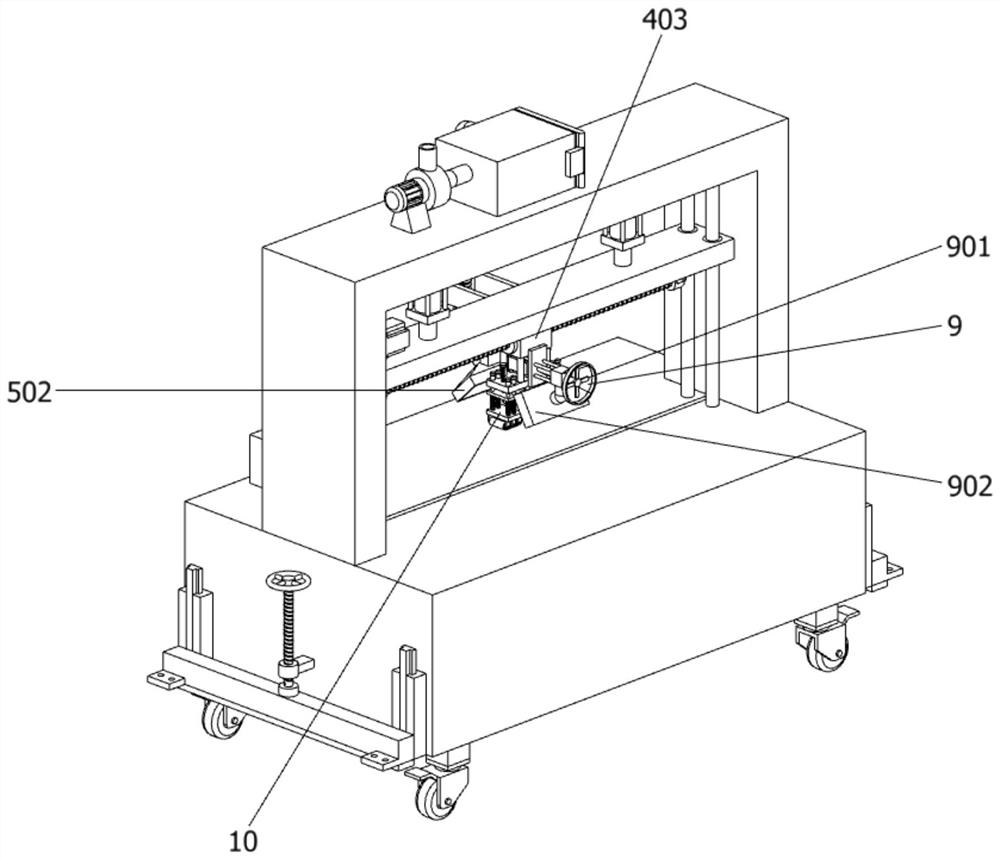

[0034] as attached figure 1 to attach Figure 10 Shown:

[0035] The present invention provides an intelligent textile new material cutting device for textiles, which includes: a base 1, the middle part of the upper end surface of the base 1 is fixedly connected with a 匚-shaped support 2, and the inner top of the 匚-shaped support 2 is provided with a lifting mechanism 3, and the lifting mechanism 3 includes The hydraulic telescopic cylinder 301, the lifting mechanism 3 is a rectangular plate structure, and the four angles of the lifting mechanism 3 are all slidably connected with a limit sliding column fixed between the upper end surface of the base 1 and the inner top surface of the 匚-shaped bracket 2, The number of hydraulic telescopic cylinders 301 is two, and the two hydraulic telescopic cylinders 301 are respectively installed on the left and right sides of the inner top surface of the Yi-shaped support 2, and the lower ends of the telescopic rods of the two hydraulic te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com