Environment-friendly garment fabric finishing and drying device

A drying device, an environmentally friendly technology, applied in the field of clothing fabrics, can solve the problems of easy adhesion of fluff, debris, easy to appear wrinkles, low drying efficiency, etc., to improve drying quality and drying efficiency, and even heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

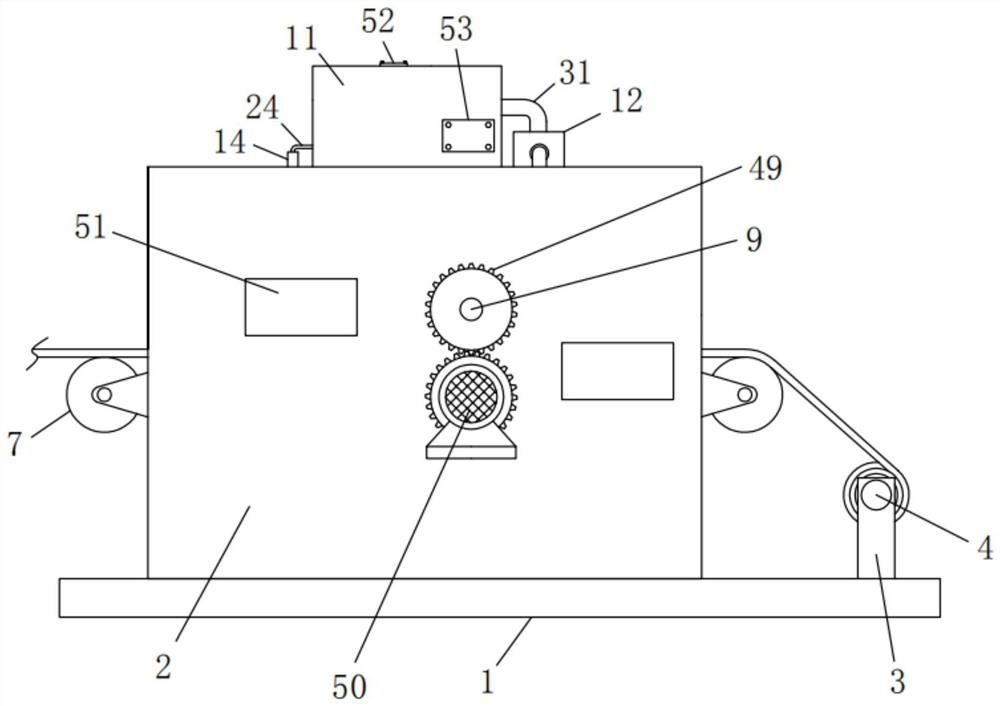

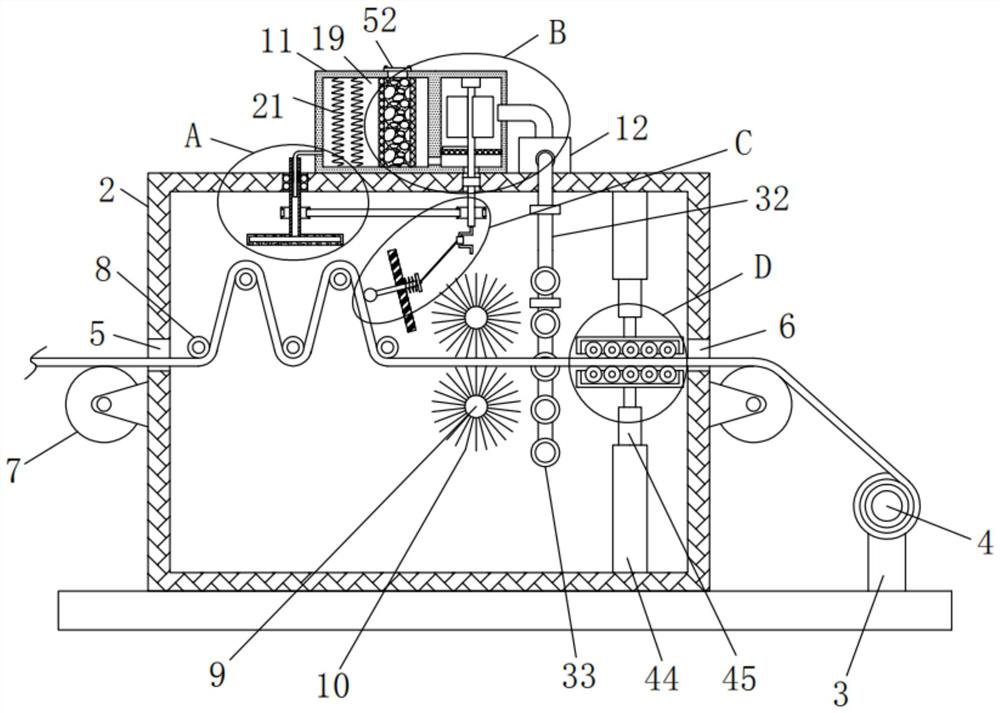

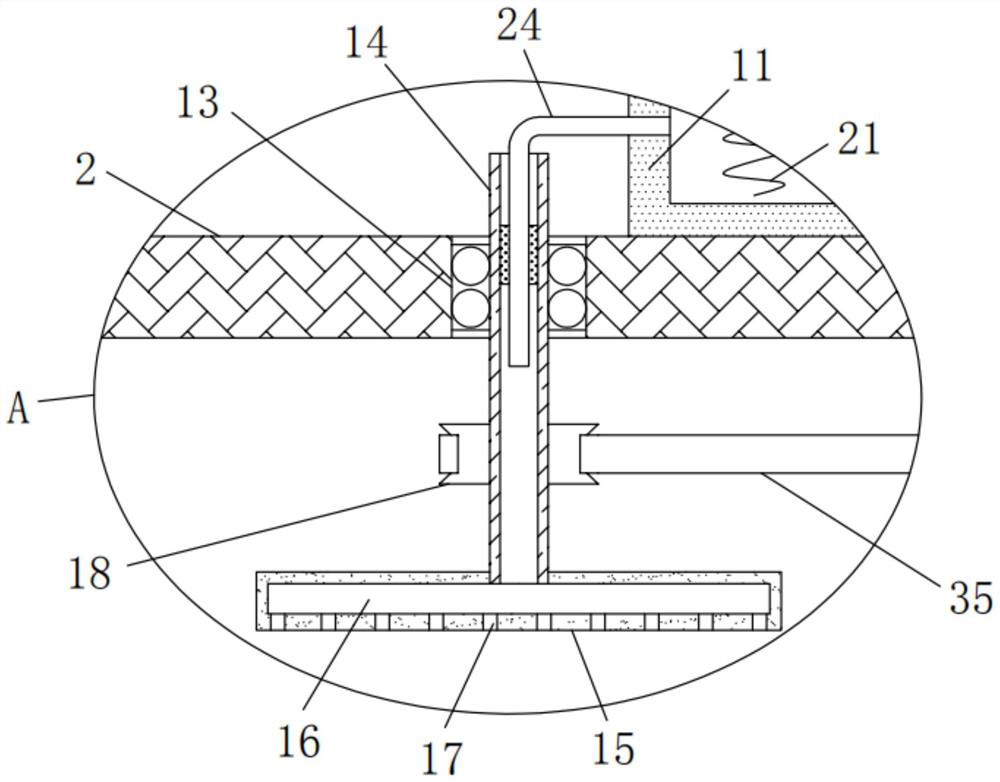

[0028] as Figure 1-6

[0029] In the present embodiment, the inner wall of one side of the drying box 2 is provided with two rectangular viewing holes, and both rectangular viewing holes are fixedly mounted with a viewing mirror 51.

[0030] In the present embodiment, the top inner wall of the heating chamber 19 is provided with a first cleaning port located between the two mesh plates 22, the top of the heating chamber 11 is bolted to be installed with a first cover plate 52, the first cover plate 52 is adapted to the first cleaning port.

[0031] In the present embodiment, the dust removal chamber 20 is provided with a second cleaning port on the inner wall on one side, and the side of the heating chamber 11 is bolted to the second cover plate 53, the second cover plate 53 is adapted to the second cleaning port.

[0032] In the present embodiment, the hollow shaft 14 on the fixing sleeve is provided with a first bearing, the outer ring of the first bearing and the mounting hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com