Soft laser self-adhesive label film and preparation method thereof

A soft, laser technology, applied in the direction of chemical instruments and methods, lamination, instruments, etc., can solve the problems of extreme softness, high followability, inability to meet the use characteristics of hoses, insufficient softness and followability, etc. Achieving the effect of good decorative effect, avoiding deformation and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

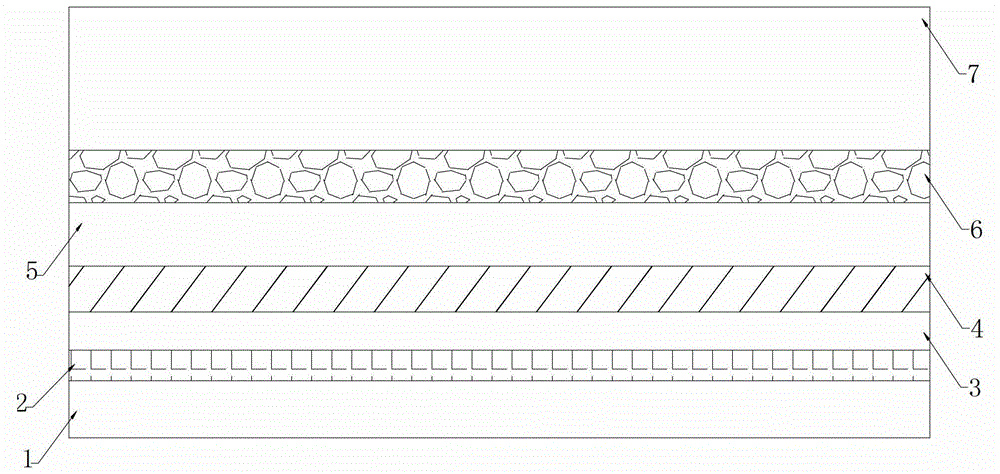

[0033] Please refer to figure 1 , The flexible laser self-adhesive label film of the present invention comprises a polyolefin film layer 7, a polyurethane glue layer 6, an aluminized layer 5, an imaging layer 4, a peeling layer 3, a pressure-sensitive adhesive layer 2, and PET silicone oil from top to bottom. For the paper layer 1, the polyolefin film layer 7 has a longitudinal softness of 80-110mN and a transverse softness of 60-90mN. The polyolefin film layer 7 is preferably a soft PVC film layer. The softness of the polyolefin film layer 7 is measured according to the national standard GB / T 8942-2002. The test instrument is a hand-feel softness tester. The temperature of the test environment is 23°C and the relative humidity is 60%. The seam width is 20.0mm.

[0034] The preparation method of above-mentioned soft laser self-adhesive label film is:

[0035] 1) Using transparent PET film as the molded base material, coating the peeling layer 3, imaging layer 4, and alumini...

Embodiment 2

[0041] The difference between this example and Example 1 is that in order to avoid the deformation of the surface material of the soft laser label, the removal of the transparent PET film and the coating of the composite pressure-sensitive adhesive are carried out at the same time in step 5). The specific operation method is: Install the recovery guide roller at a distance of 20cm from the composite station of the cloth machine, and then install the active tension recovery roller 1m above the recovery guide roller, and place the composite pressure-sensitive adhesive layer on the composite station of the scraper coater First, put the soft laser label surface material on the unwinding station of the scraper coater, pull the soft laser label surface material to the compound station through the traction guide roller, and automatically The tension recovery roller begins to peel off the transparent PET film of the soft laser label surface material, and the soft laser label surface ma...

Embodiment 3

[0043]The difference between this embodiment and Embodiment 1 is that the thickness of the soft PVC film layer is 50-120 μm, and when the soft PVC film layer is too thick, the softness is poor, and the followability of the product is also poor, so it cannot be compared with the soft PVC film layer. tubes or squeezable bottles for a perfect fit, polyolefin film layers that are too thin have too little stiffness for automatic labeling on the production line with a labeling machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com