Film sticking machine capable of automatically tearing off release paper

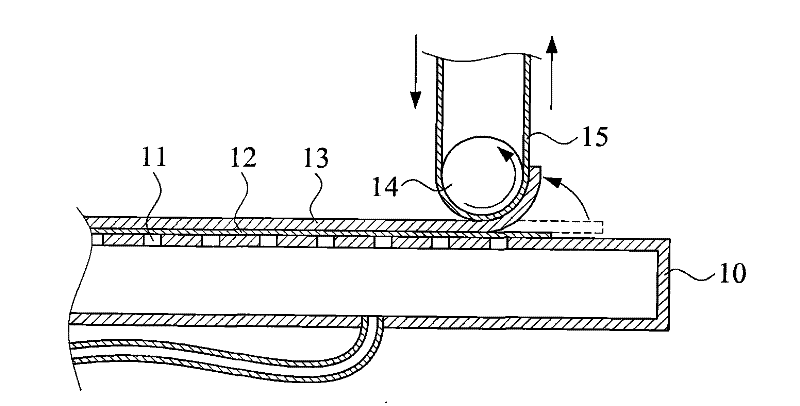

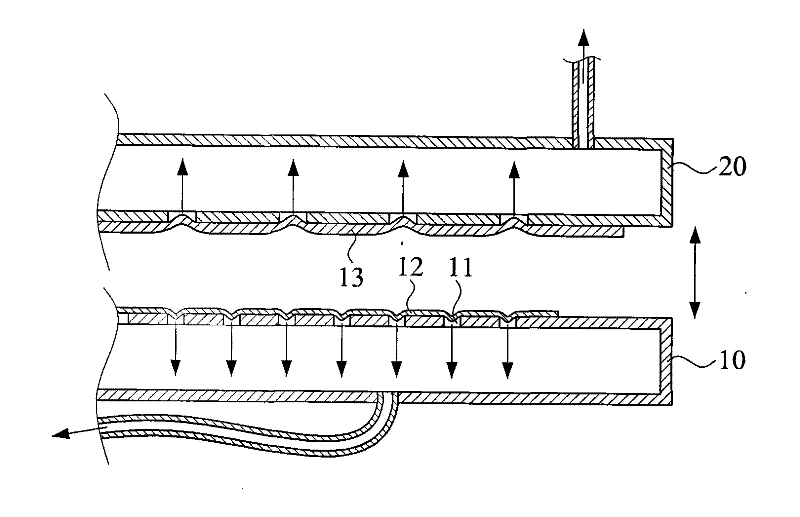

A release paper and film laminating machine technology, which is applied in the directions of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of increased cost, wrinkled adhesive film 12, consumption of consumables of tape 15, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

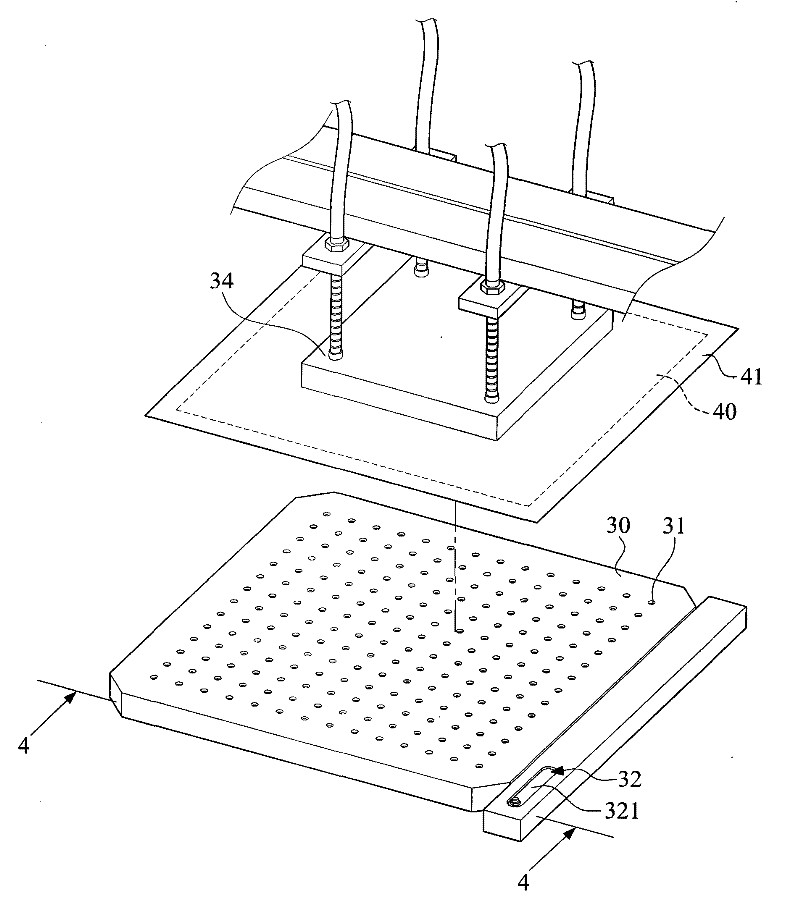

[0025] Referring to Figures 3, 4 and 5, the embodiment 1 of the present invention provides a film laminating machine that can automatically tear off the type paper, which is provided with a platform 30, and the platform 30 is provided with a plurality of suction holes arranged in an array 31, each suction hole 31 is connected with a vacuum negative pressure suction device (not shown in the figure), and is used for a glue film 40 is adsorbed on this platform 30; This platform 30 one corners are provided with a tilting device 32, and this The tilting device 32 is provided with a push piece 321 on the platform 30, and a pusher 323 is connected below the push piece 321; the platform 30 is provided with a clamping device 33 above a release paper 41 on the upper surface of the adhesive film 40 , the clamping device 33 is provided with a track 331 diagonally opposite to the platform 30 , and a gripper 333 is arranged on the track 331 , so that the gripper 333 can move along the track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com