Feeding template used for automatic cutting of material and control method thereof

A control method and material technology, which is applied in the field of rubber machinery, can solve problems such as prolonging the feeding cycle, material wrinkling, and front-end wear of the material, and achieve the effects of reducing the workload, maintaining quality, and shortening the feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

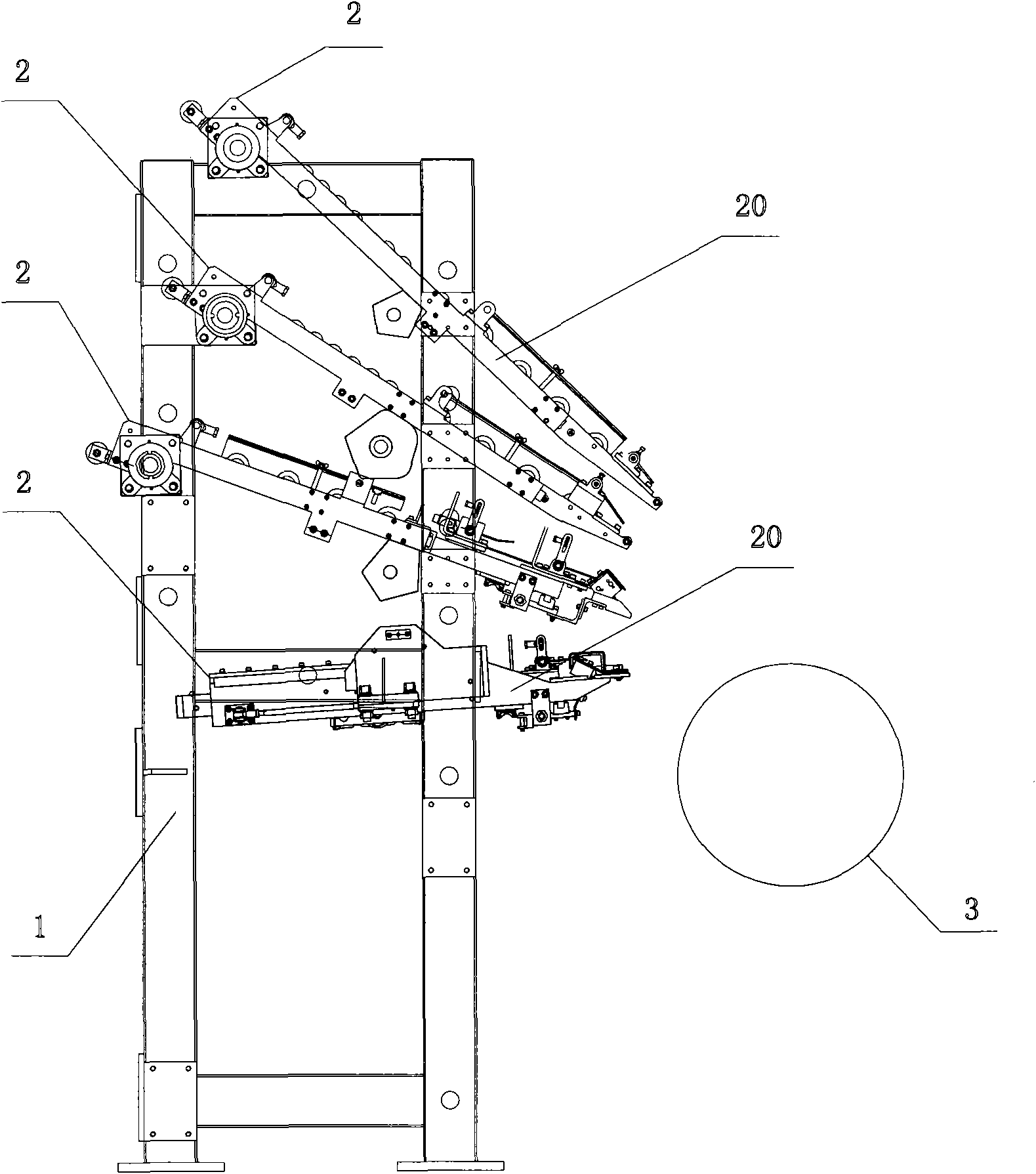

[0041] Example 1, in figure 1 In the application of the feeding device of the present invention, between the left and right wallboards 1, there are fixedly connected multiple sets of feeding templates 2 for conveying materials to the forming drum 3 to complete the material joint and lamination operation.

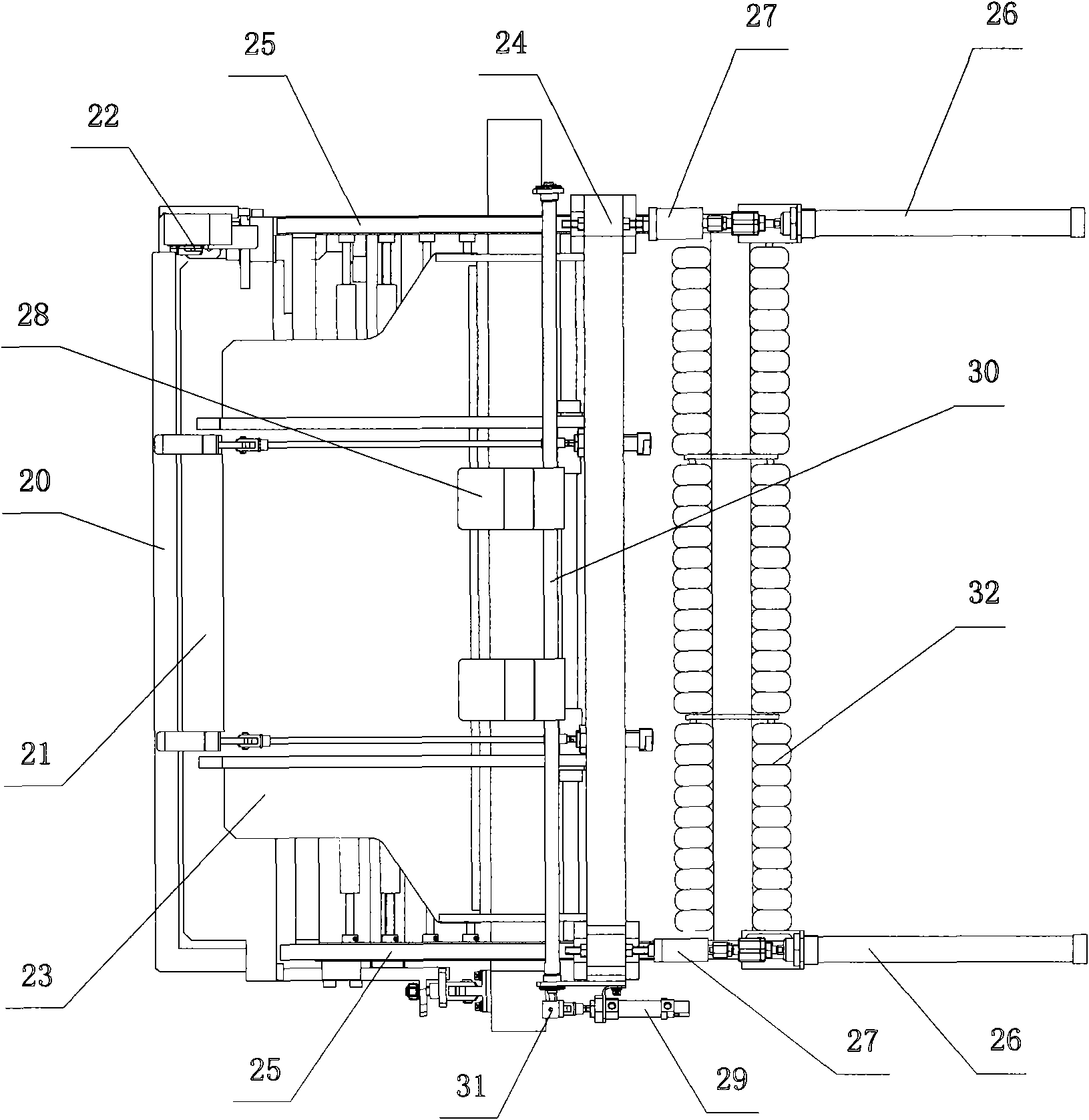

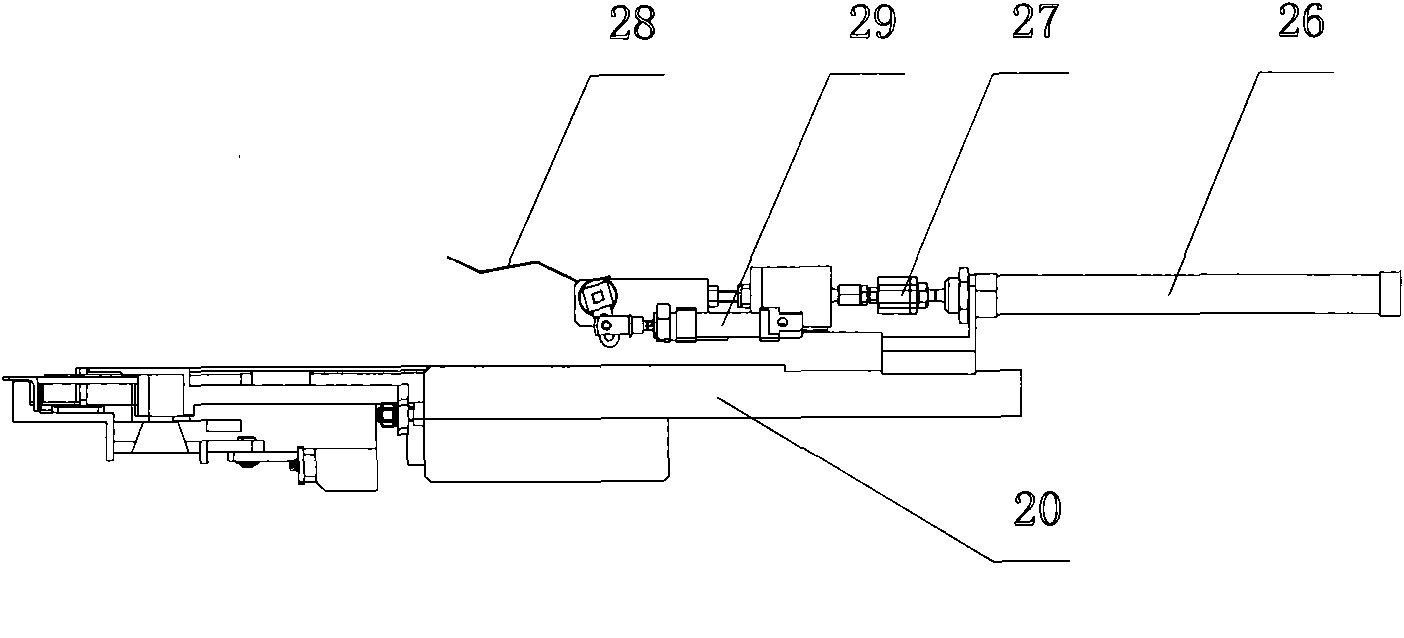

[0042] like figure 2 and image 3 As shown, the feeding templates for material conveying and automatic cutting mainly include:

[0043] a frame 20,

[0044] A plurality of groups of conveying rollers 30 for longitudinally conveying materials are arranged on the frame 20 .

[0045] A front end plate 21 and a cutting knife 22 for horizontally cutting materials are arranged at the front end of the frame 20 , and a longitudinal feeding device is arranged at the rear side of the front end plate 22 .

[0046] Wherein, the longitudinal feeding device has a feeding plate 23 that carries materials upwards and conveys materials to the forming drum 3 along the longitudinal directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com