Thin film tension floating adjusting device for storage bag preparation

A technology for adjusting device and film tension, applied in packaging, bag making, thin material handling, etc., can solve problems such as stretching deformation, affecting the quality of storage bags, wrinkling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

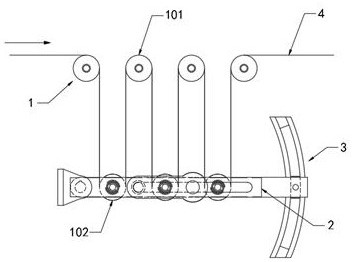

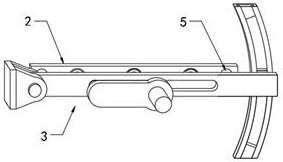

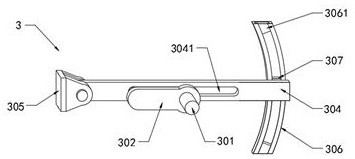

[0031] Such as Figure 1-6 As shown, an embodiment of the present invention proposes a film tension floating adjustment device for storage bags. The tension floating adjustment device includes:

[0032] Roller group 1 is composed of a number of fixed rollers 101 and floating rollers 102 arranged equidistantly up and down. During use, the fixed rollers 101 are fixed. Due to the requirements of the storage bag preparation process such as opening holes and welding valves, it is necessary to cooperate with the rear end of the production line. The film 4 is advanced in a step-by-step manner, and the floating roller 102 is set to control the film 4 from being damaged, wrinkled, and stretched under the condition of tension changes; 102 is used to alternately pull the film 4, such as figure 1 shown;

[0033] The floating bracket 2 is arranged under the fixed roller 101, and is used for installing and fixing the floating roller 102. During installation, the floating roller 102 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com