Mask and frame assembly of mask tensioning machine for deposition process

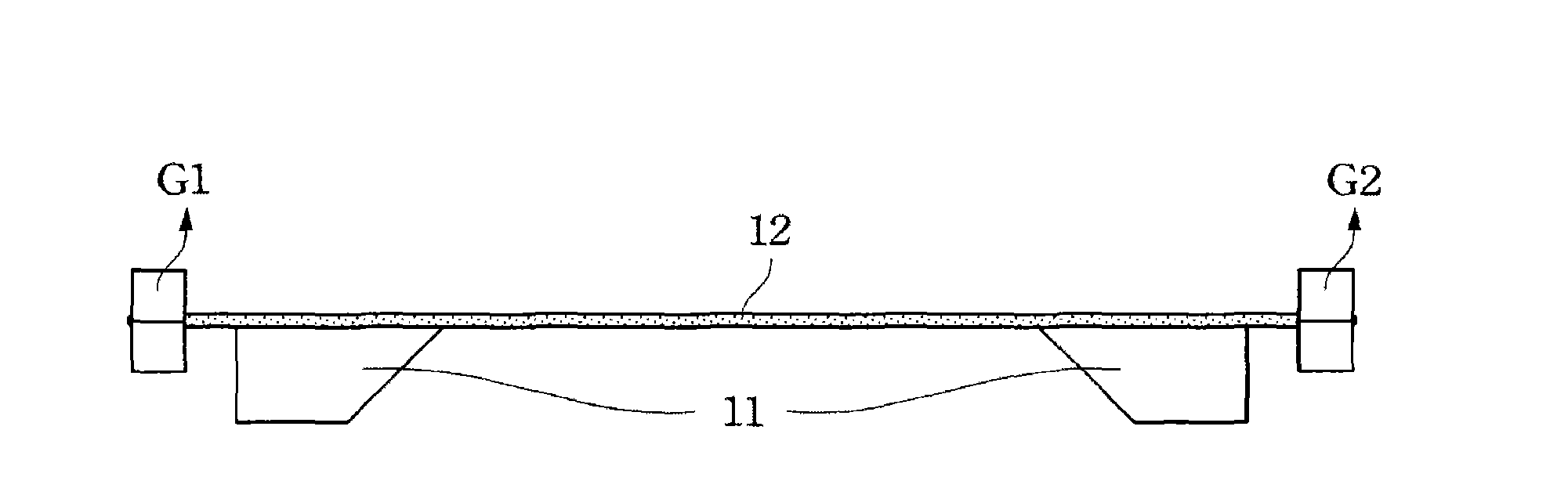

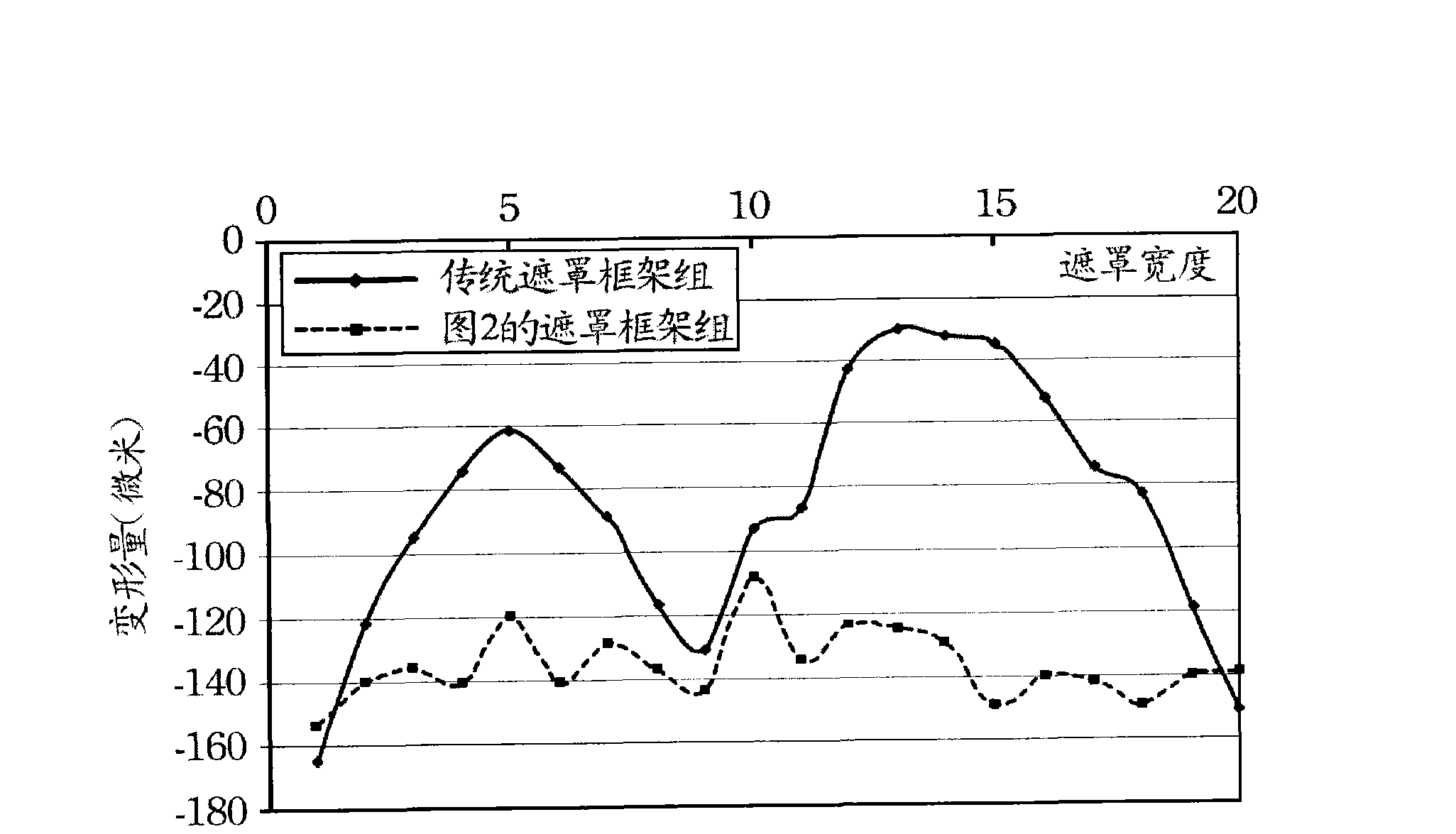

A mask sheet and mask technology, applied in the field of deposition process, can solve the problems of mask 12 wrinkling, shadow effect, uneven strength, etc., and achieve the effect of avoiding shadow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical content disclosed in this application more detailed and complete, reference may be made to the drawings and the following various specific embodiments of the present invention, and the same symbols in the drawings represent the same or similar components. However, those skilled in the art should understand that the examples provided below are not intended to limit the scope of the present invention. In addition, the drawings are only for schematic illustration and are not drawn according to their original scale.

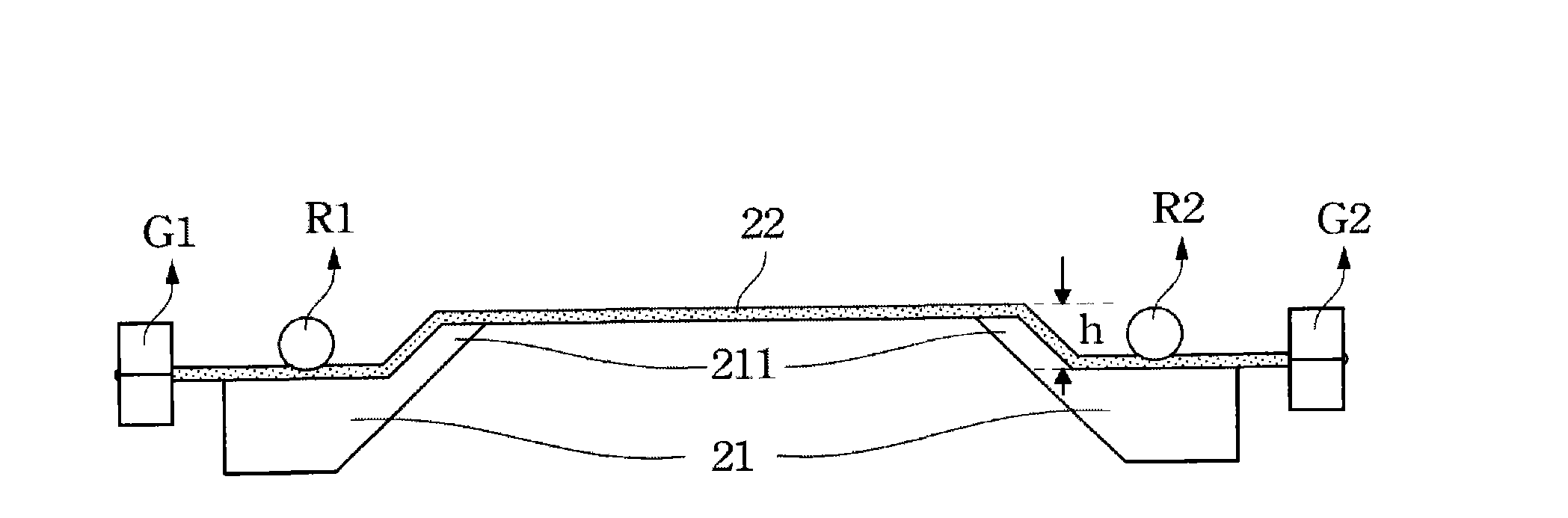

[0019] refer to figure 2 , figure 2 A front view of a mask frame set of a mask tensioner for a deposition process according to an embodiment of the present invention is shown.

[0020] The mask frame group of the mask tensioner includes a frame body 21 and a mask 22 . Wherein, the frame body 21 has a protruding portion 211 around its periphery, that is, the surrounding surface of the frame body 21 is the protruding portion 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com