Construction method of gypsum cast-in-place wall

A construction method and technology of cast-in-place walls, applied in the processing of building materials, walls, manufacturing tools, etc., can solve the problems of high construction quality requirements, low construction efficiency, and affecting construction efficiency, and achieve high construction efficiency and high construction speed Fast, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The embodiments of the present invention all use the paper-free fiber-free high-strength gypsum board prepared with phosphogypsum as the raw material described in the patent application number 20201113379.1. Specifically, the preparation method of the gypsum board specifically includes the following steps:

[0034] S1. Drying and dehydration: drying and dehydrating phosphogypsum at 150-180°C under normal pressure to obtain phosphogypsum hemihydrate;

[0035] S2. Compression molding: Mix the hemihydrate phosphogypsum obtained in S1 with water at a mass ratio of 100:10-30, and stir quickly and evenly, then transport the water-mixed hemihydrate phosphogypsum into the mold, and heat it at 5-25MPa After pressing and pressing under pressure to form a gypsum board, demoulding;

[0036] S3. Water spray hydration: place the gypsum board obtained in S2 on the roller conveying device, and run forward with the roller conveying device for 10 to 30 minutes. During this period, continuo...

Embodiment 1

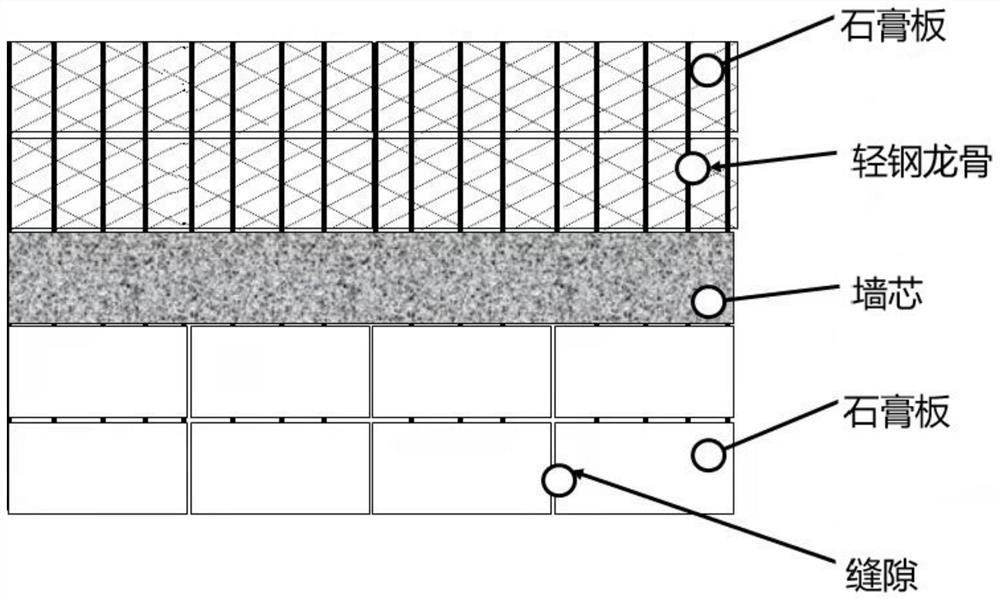

[0042] S1. Install the light steel keel: according to the wall thickness of 120mm, select the light steel keel with a vertical keel width of 100mm, and install the jackie keel according to the conventional construction method;

[0043] S2. Riveting the gypsum board: choose a 10mm thick gypsum board as the wall panel, and use screws to rivet the gypsum board on both sides of the dragon frame to form the wall surface of the proposed wall and serve as a cavity for the subsequent pouring of the wall core The role of the mold box, wherein the gypsum board has played the role of a permanent template; it should be noted that each side wall of the present invention is spliced by multiple pieces of gypsum board;

[0044] S3. Filling: Use plaster of paris powder as raw material, and mix water and plaster of paris powder in a ratio of 50:100 to prepare gypsum paste, and fill the plaster paste into two adjacent gypsum boards In the gap between them, it plays a role of caulking, and at t...

Embodiment 2

[0049] S1. Install the light steel keel: according to the wall thickness of 180mm, select the light steel keel with a vertical keel width of 150mm, and install the jackie keel according to the conventional construction method;

[0050] S2. Riveting the gypsum board: choose a 15mm thick gypsum board as the wall panel, and use screws to rivet the gypsum board on both sides of the dragon frame to form the wall surface of the proposed wall and serve as a cavity for the subsequent pouring of the wall core The role of the mold box, in which the gypsum board acts as a permanent formwork;

[0051] S3. Filling: Use plaster of paris powder as raw material, and mix water and plaster of paris powder in a ratio of 50:100 to prepare gypsum paste, and fill the plaster paste into two adjacent gypsum boards In the gap between them, it plays a role of caulking, and at the same time, it can avoid the leakage of the subsequent pouring of gypsum slurry; it should be noted that the gypsum paste in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com