Heating device and electronic cigarette

A heating device and heating part technology, applied in the field of electronic cigarettes, can solve problems such as poor stability, falling off of resistance heating elements, poor consistency of resistance heating elements, etc., and achieve stability, stability and consistency of resistance value and temperature variation coefficient Good, good heating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

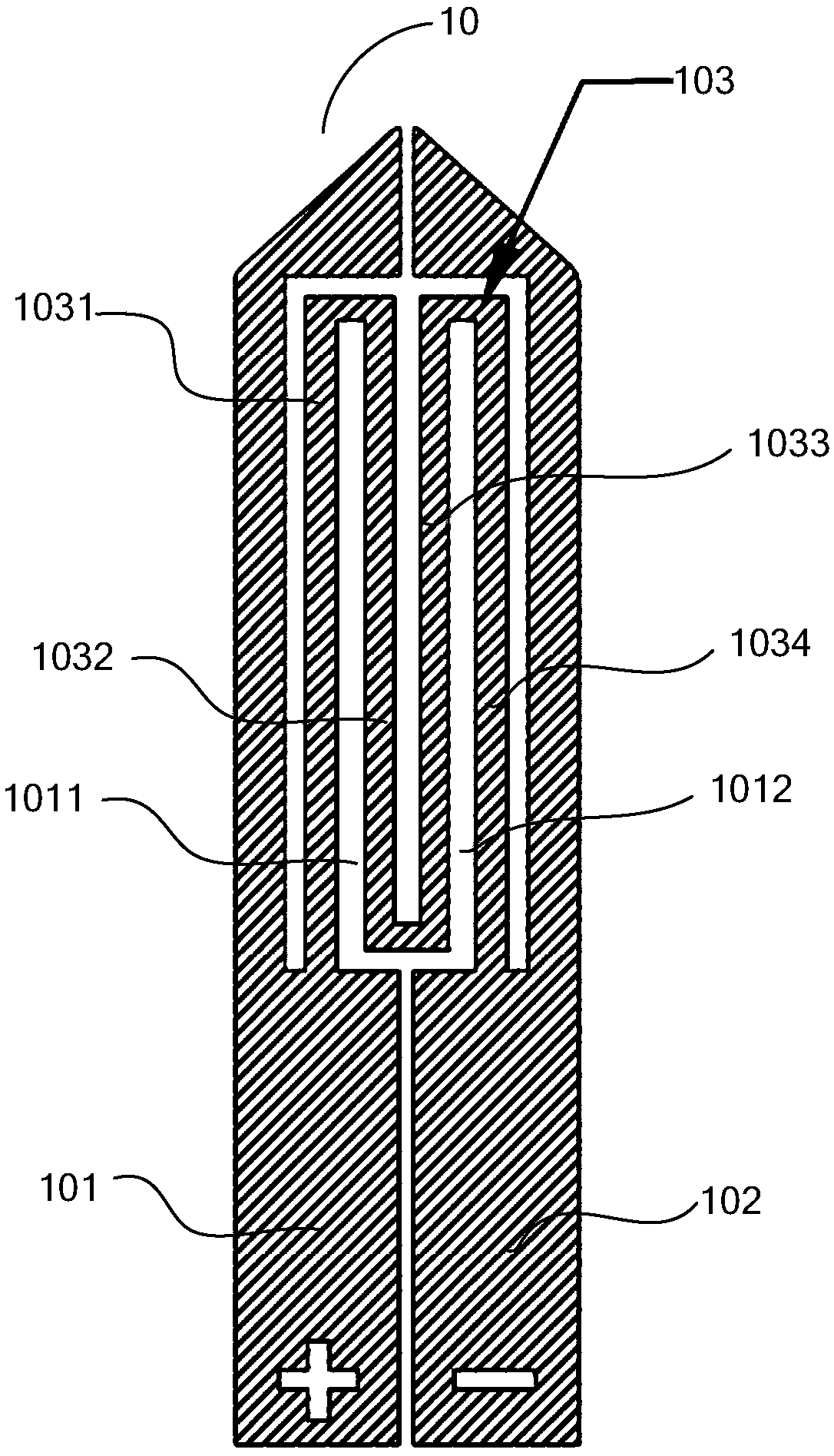

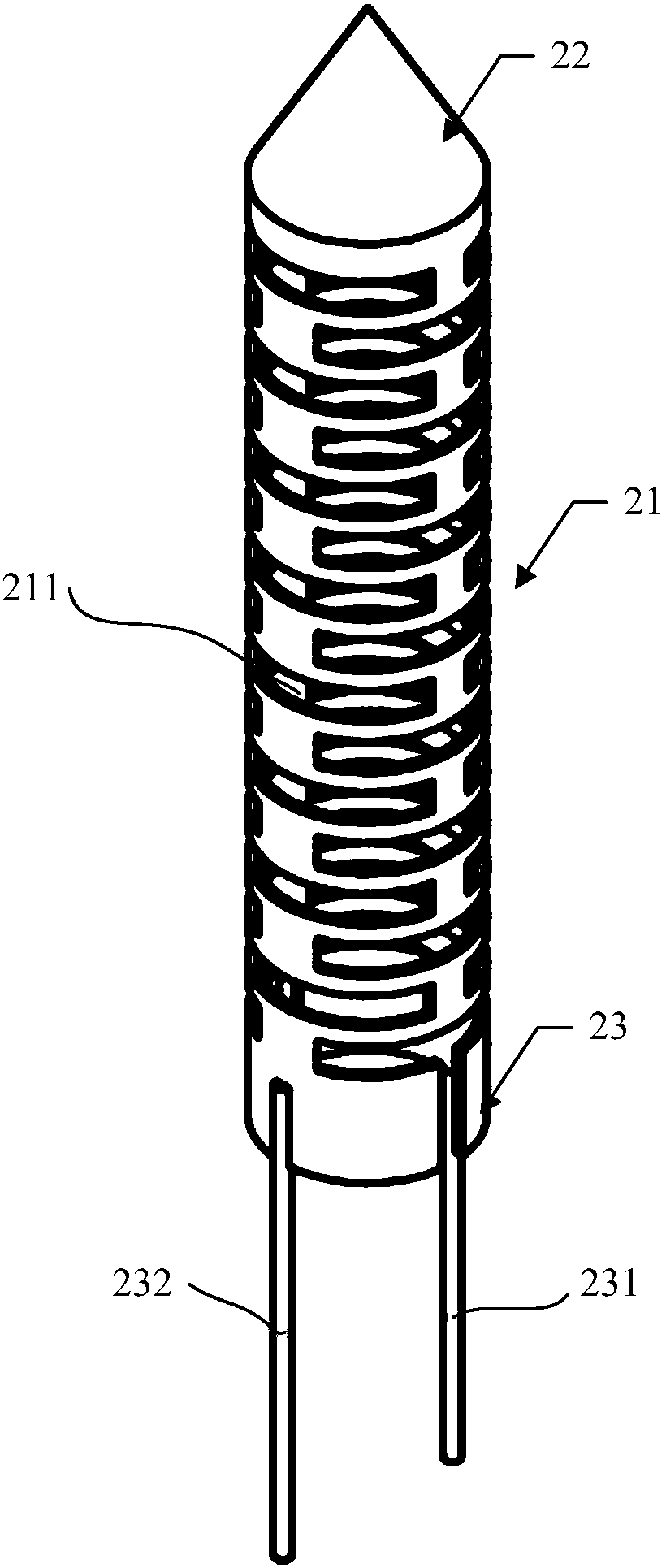

[0029] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

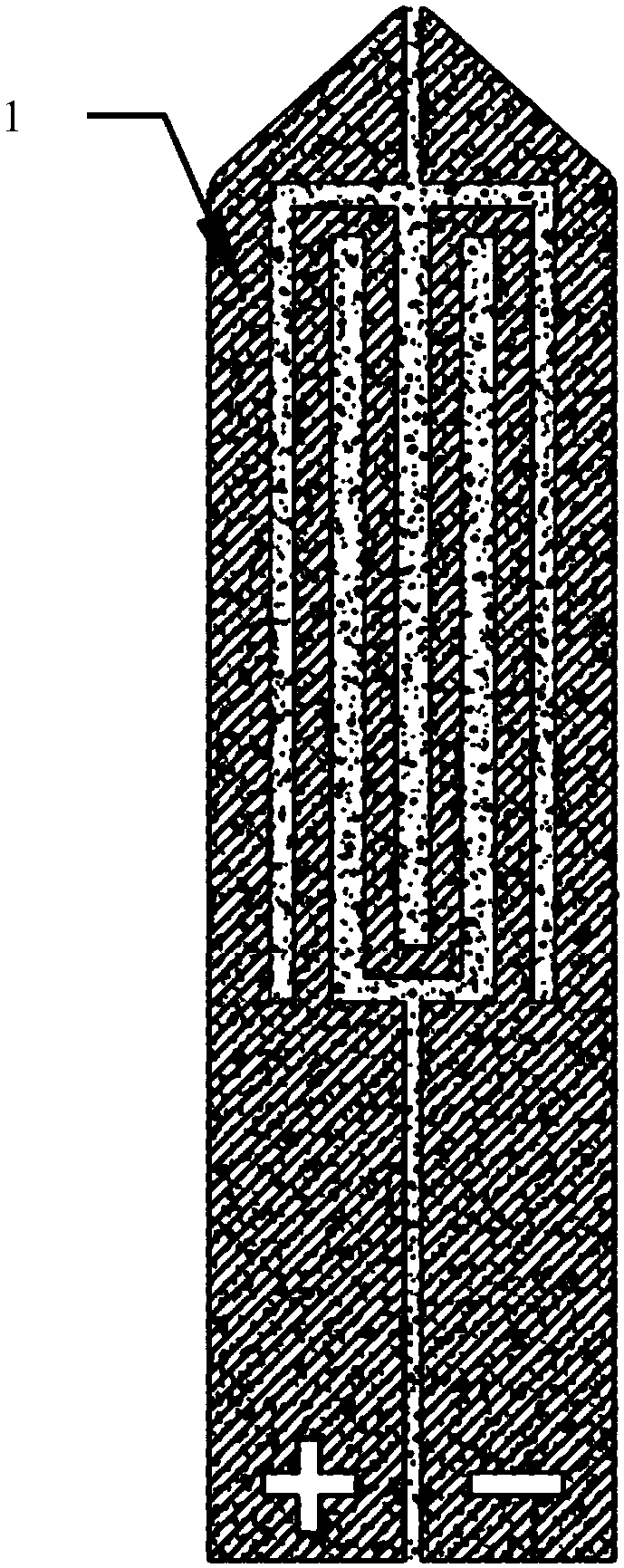

[0030] In order to solve the structure that the heating element in the existing electronic cigarette or electronic cigarette device is based on ceramics and the heating element is printed on the ceramic substrate, there are easy to fall off, poor stability, and poor heating consistency, and the temperature of the heating element cannot be accurately controlled. problem, the present invention provides a new type of heating device, the heating device does not use ceramics or other materials as the substrate, does not need to print heating elements on the ceramic substrate, but directly uses a heating element formed at one time, which can save The technological process can also improve the heating consistency of the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com