Electrode plate preparation method applied to all-vanadium redox flow battery, electrode plate and preparation device

A technology of all-vanadium redox flow battery and pole plate, which is applied in electrode manufacturing, electrode rolling/calendering, fuel cells, etc., to achieve the effect of strong air tightness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

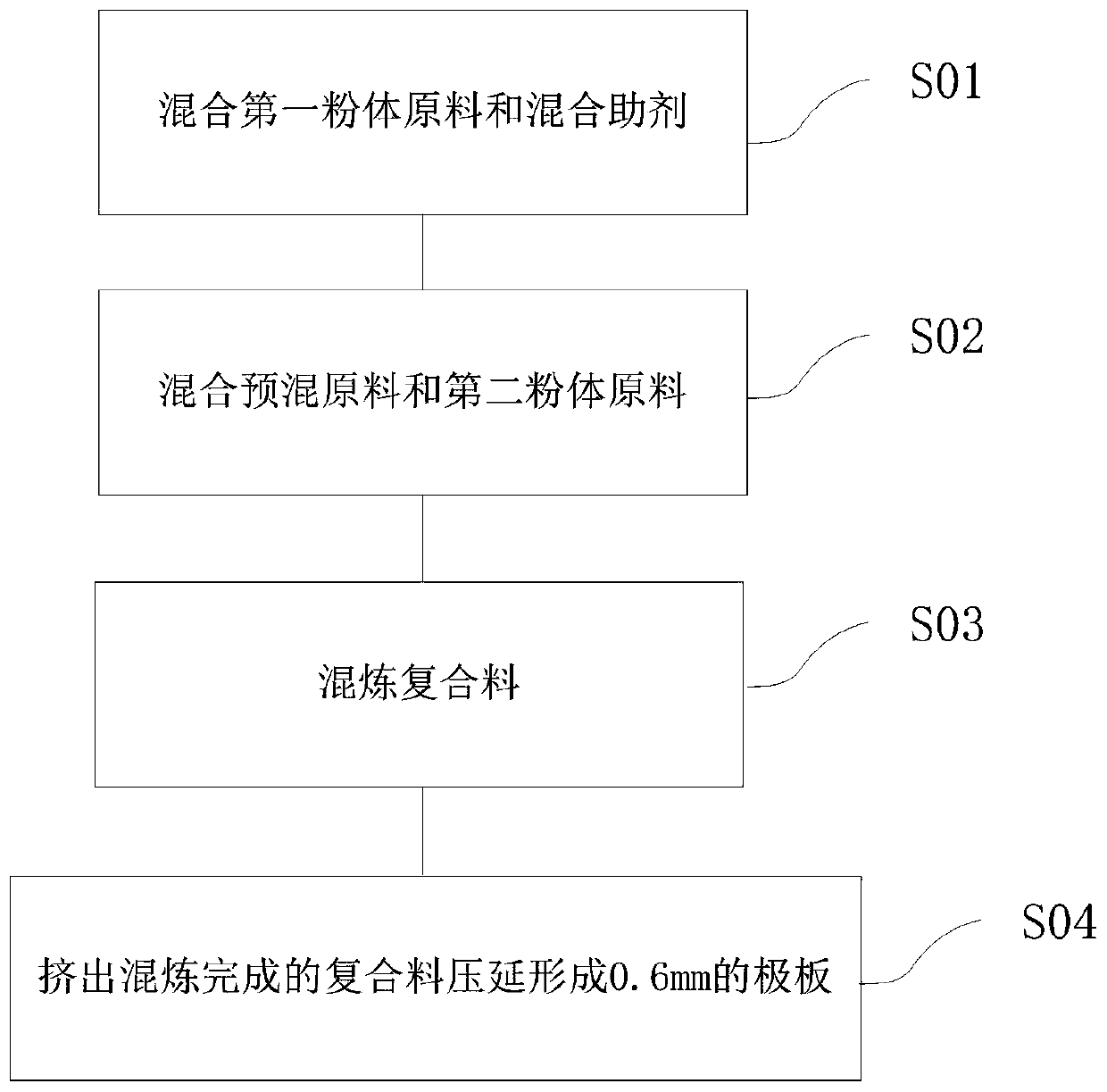

[0023] Embodiment 1 of the present invention: a method for preparing a pole plate applied to an all-vanadium redox flow battery, comprising the following steps: Step S01: mixing the first powder raw material and a mixing aid to obtain a premixed raw material; wherein, to ensure that the To prepare the resistivity of the plate, the first powder raw material includes carbon black powder, graphite powder and carbon nanotube powder, and the mixing aid uses a powder silane coupling agent; step S02: mixing the premixed raw material and the second powder body raw material to obtain composite material; wherein the second powder raw material includes HDPE (high density polyethylene) powder, PP (polypropylene) powder and SEBS (hydrogenated styrene-butadiene-styrene block copolymer) powder body; step S03: import the compound material into the blanking device, and the compound material is mixed in the screw mixing section of the extruder; the compound material is mixed in the screw mixing ...

Embodiment 2

[0029] Embodiment 2 of the present invention: a method for preparing a pole plate applied to an all-vanadium redox flow battery, comprising the following steps:

[0030] Step S01: Mix the first powder raw material and mixing auxiliary agent to obtain premixed raw material; wherein the first powder raw material includes carbon black powder, graphite powder and carbon nanotube powder, and the mixing auxiliary agent adopts powder silane coupling agent; step S02: mix the premixed raw material and the second powder raw material to obtain a composite material; wherein the second powder raw material includes HDPE powder, PP powder and SEBS powder; step S03: import the composite material into the blank device, the compound material is mixed in the screw mixing section of the extruder; the compound material is mixed in the mixing section through the extruder, and the mixing temperature is 225 °C; step S04: the compound material that is extruded and mixed is calendered to form 0.6mm pla...

Embodiment 3

[0035] Embodiment 3 of the present invention: a method for preparing a pole plate applied to an all-vanadium redox flow battery, comprising the following steps:

[0036] Step S01: Mix the first powder raw material and mixing auxiliary agent to obtain premixed raw material; wherein the first powder raw material includes carbon black powder, graphite powder and carbon nanotube powder, and the mixing auxiliary agent adopts powder silane coupling agent; step S02: mix the premixed raw material and the second powder raw material to obtain a composite material; wherein the second powder raw material includes HDPE powder, PP powder and SEBS powder; step S03: import the composite material into the blank device, the compound material is mixed in the screw mixing section of the extruder; the compound material is mixed in the mixing section through the extruder, and the mixing temperature is 205 °C; Step S04: the compound material that is extruded and mixed is calendered to form 0.6mm pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com