Mechanical seal test device for nuclear main pump

A mechanical seal and test device technology, applied in the direction of pump testing, mechanical equipment, liquid variable capacity machinery, etc., to achieve the effect of eliminating axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

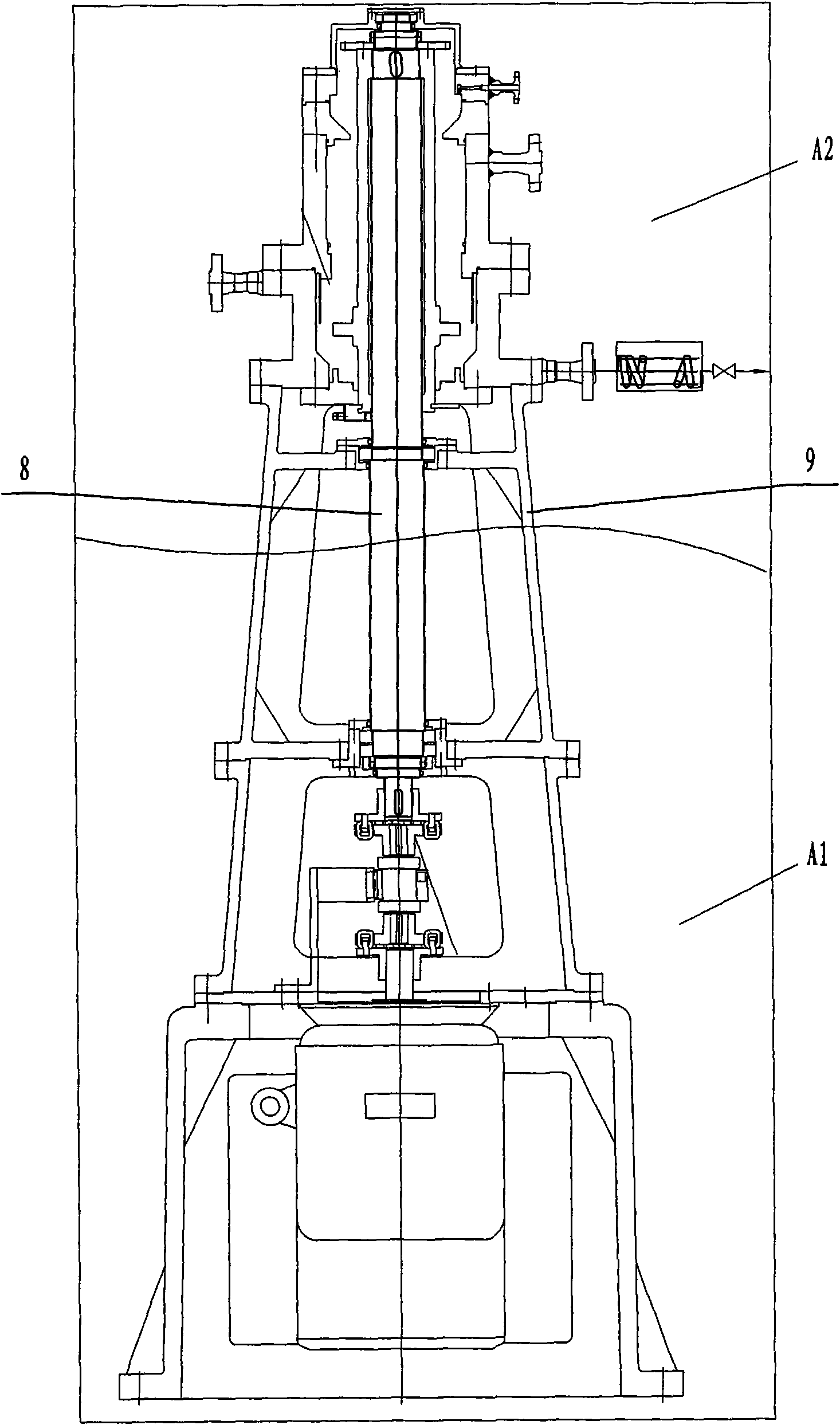

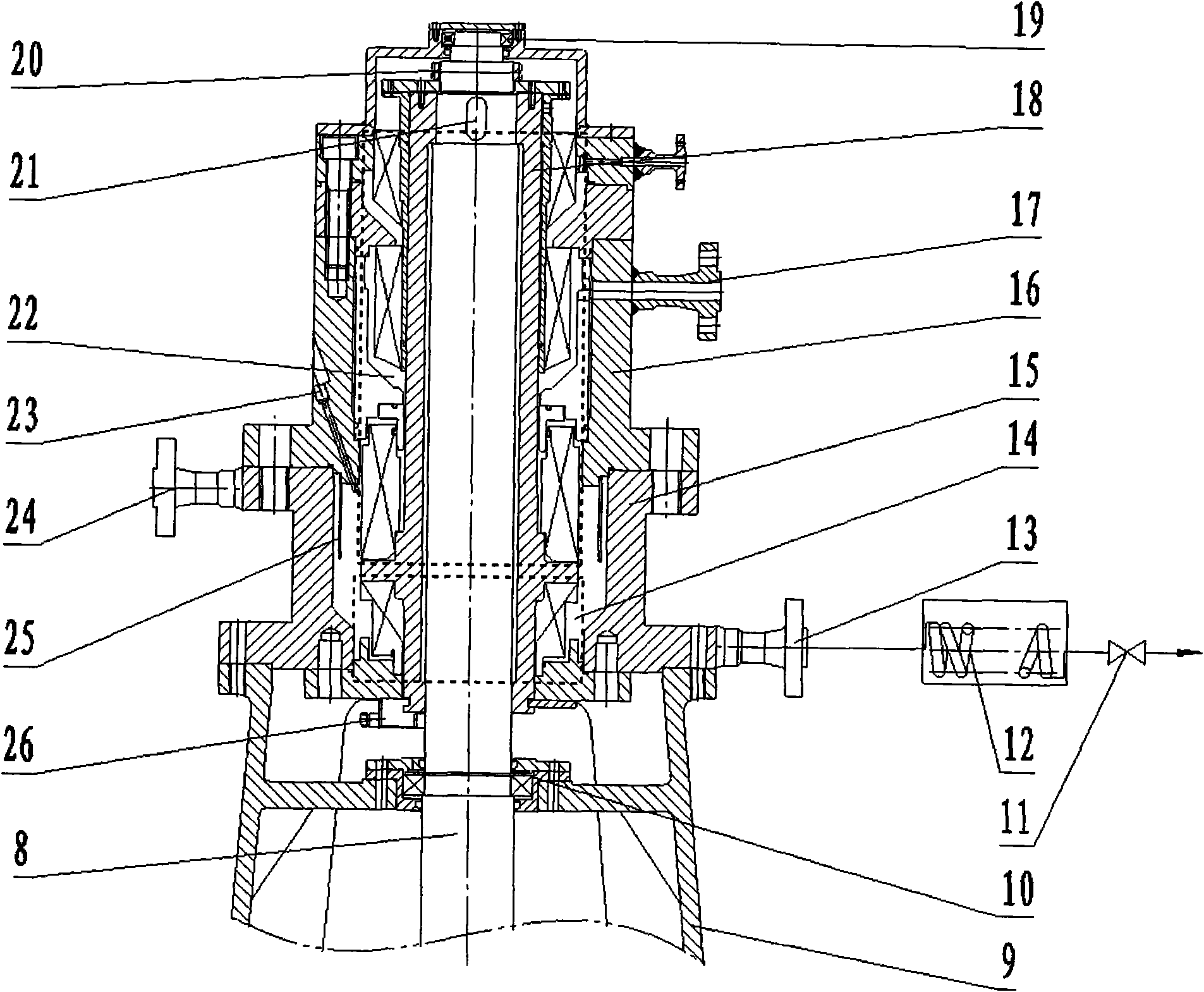

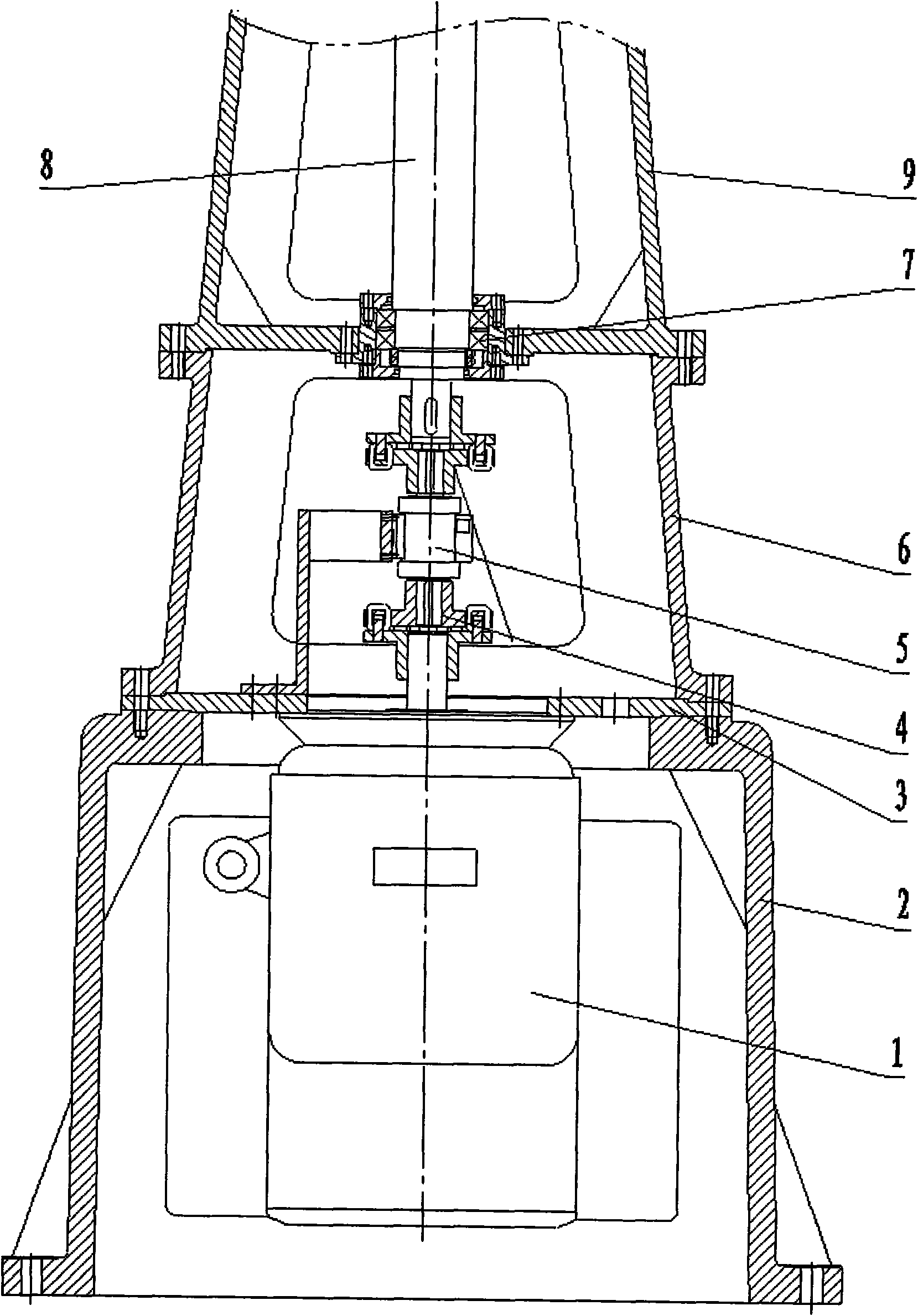

[0024] see figure 1 , figure 2 and image 3 , this embodiment adopts the vertical structure of the bottom transmission, which can be directly driven by the motor 1, or driven by the belt transmission mode, and the stepless speed regulation is realized through the frequency converter, and the speed torque sensor 5 and the main shaft 8 are connected by the flexible coupling 4 . The main shaft 8 is supported by the lower support 7 and the upper support 10 installed on the upper frame 9 , and an auxiliary support 19 is provided on the top of the main shaft 8 . The test end of the main shaft 8 is provided with a variable diameter test shaft sleeve 18, the test shaft sleeve 18 is connected to the main shaft 8 through a key 21 for transmission, and the upper end of the main shaft 8 is pressed with a lock nut 20, and the shaft orientation.

[0025] The test frame adopts a segmented circular platform structure, which is composed of an upper frame 9 and a lower frame 6. The lower f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com