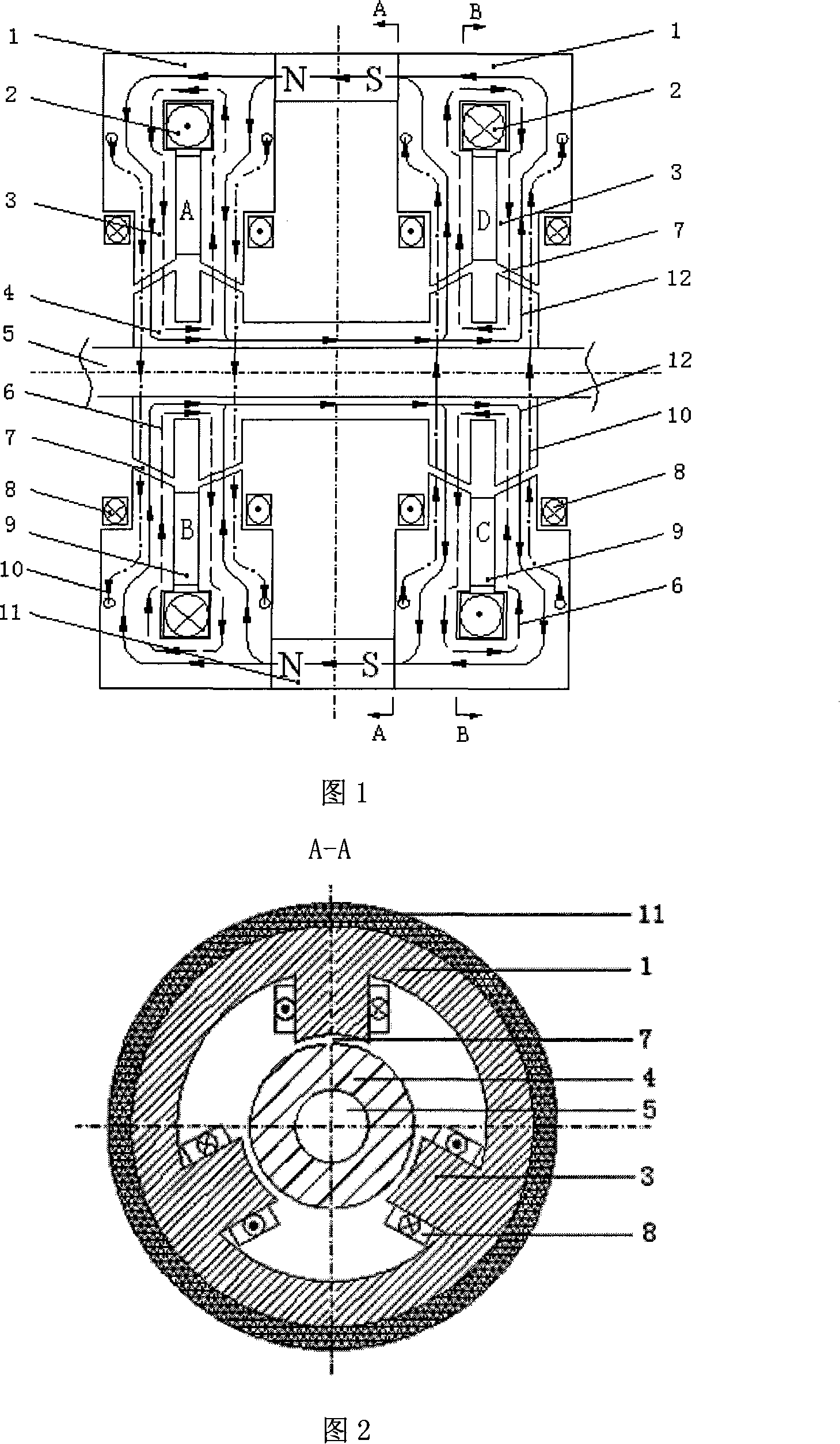

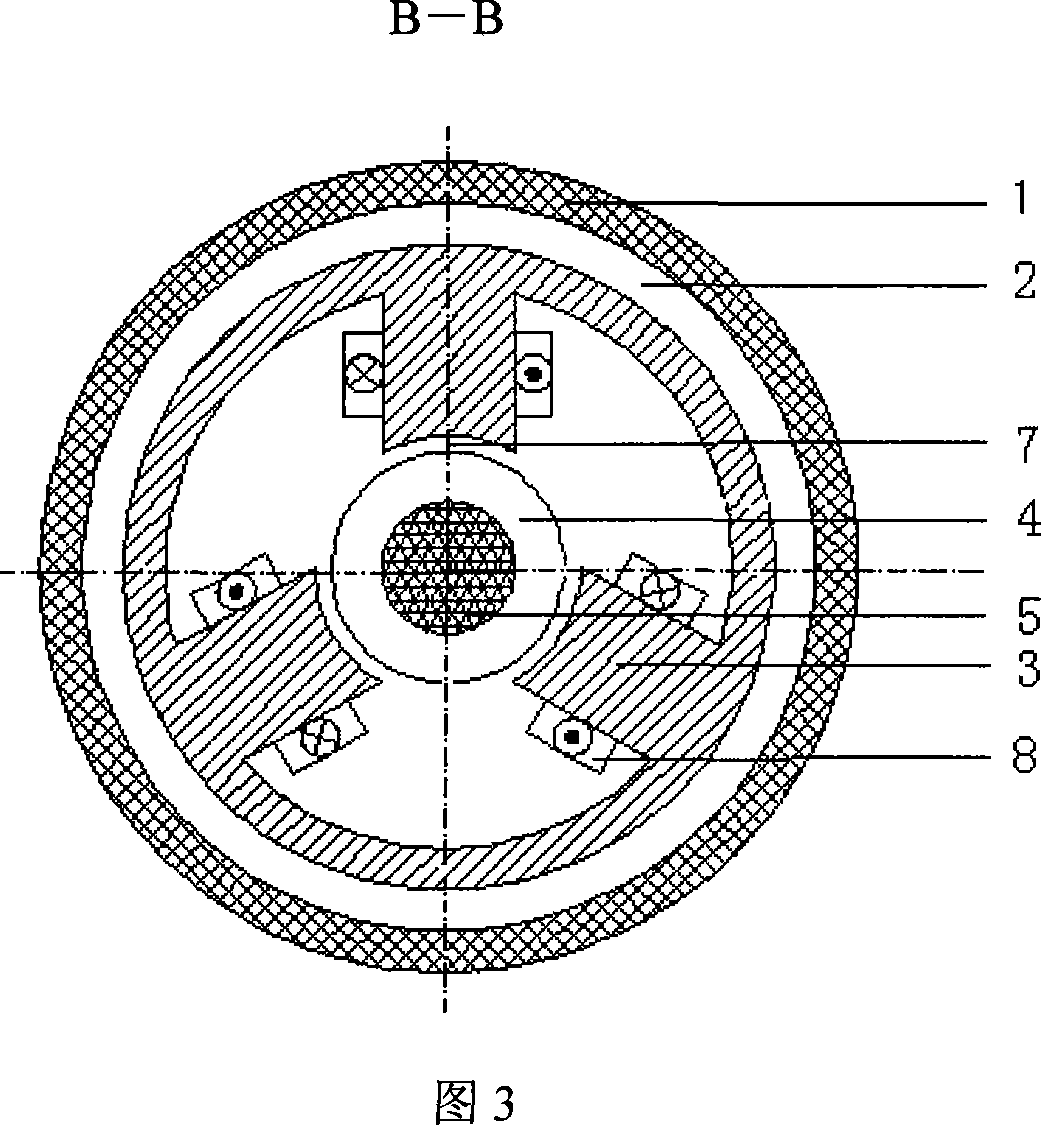

Three freedom degree conical rotor AC-DC hybrid magnetic bearing

An AC-DC hybrid, stator-rotor technology, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of increased weight, increased axial length of bearings, high cost, reduced impedance loss, increased critical speed, and increased shaft speed. The effect of decreasing in length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention firstly designs the structure and magnetic circuit of the three-degree-of-freedom conical stator-rotor AC-DC hybrid magnetic bearing, and deduces the mathematical model of the three-degree-of-freedom conical stator-rotor AC-DC hybrid magnetic bearing according to the assumed conditions of the magnetic field and the equivalent principle of the magnetic circuit , and then design the structural parameters and electrical performance parameters of the magnetic bearing according to the mathematical model and combined with the predetermined technical indicators. Based on these structural parameters, use the finite element analysis software Maxwell 3D to further optimize the design of the magnetic bearing structural parameters, and verify the correctness of the structural design principles and magnetic flux distribution. Finally, according to the mathematical model, the calculation formulas of axial suspension force and radial suspension force are further d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com