Three-freedom consequent pole permanent magnet motor without bearing of axial direction initiative suspending

A degree of freedom, bearingless technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of no patents and literature, etc., to reduce volume and power consumption, simple and compact motor structure, easy to modularize and machine processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

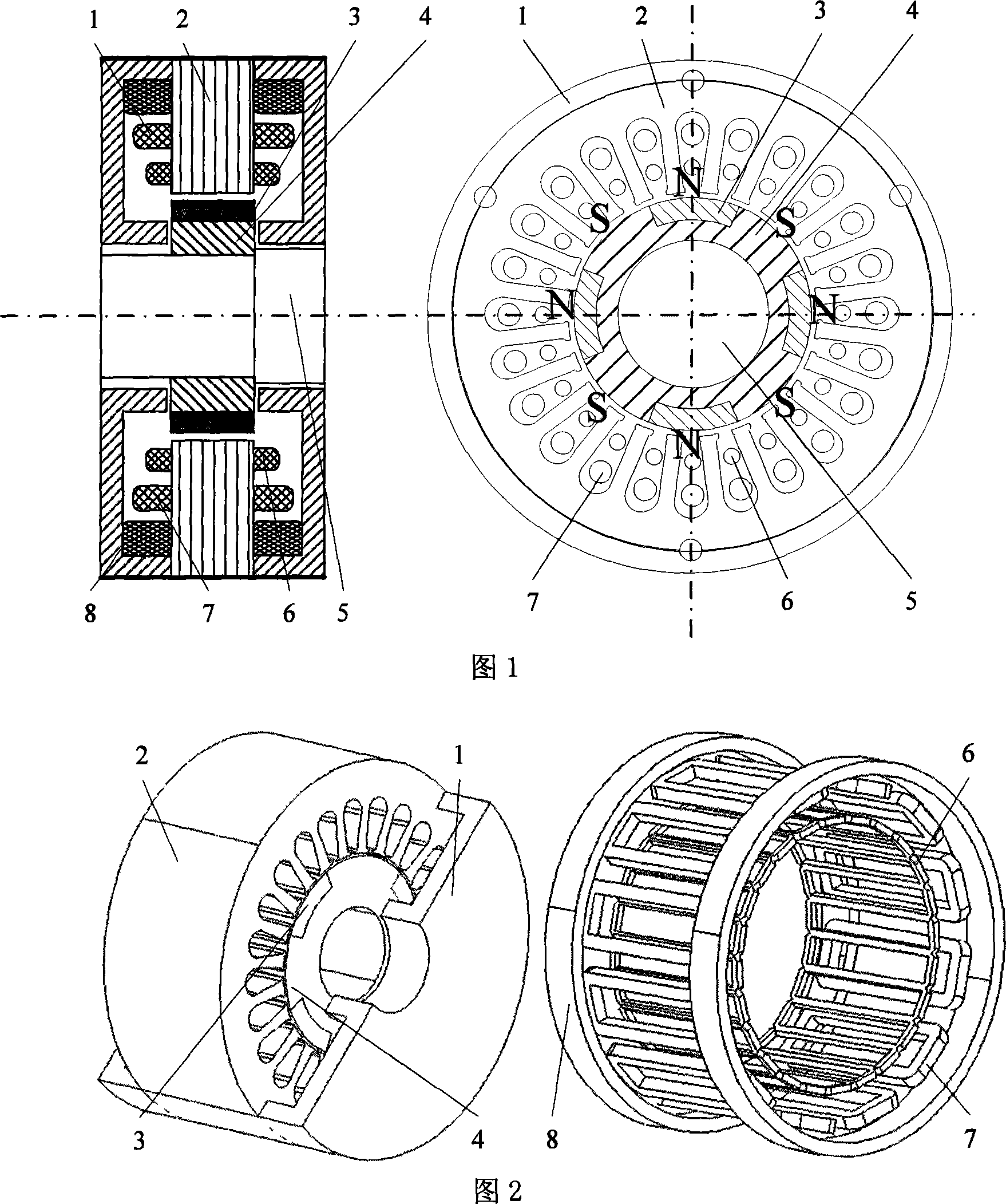

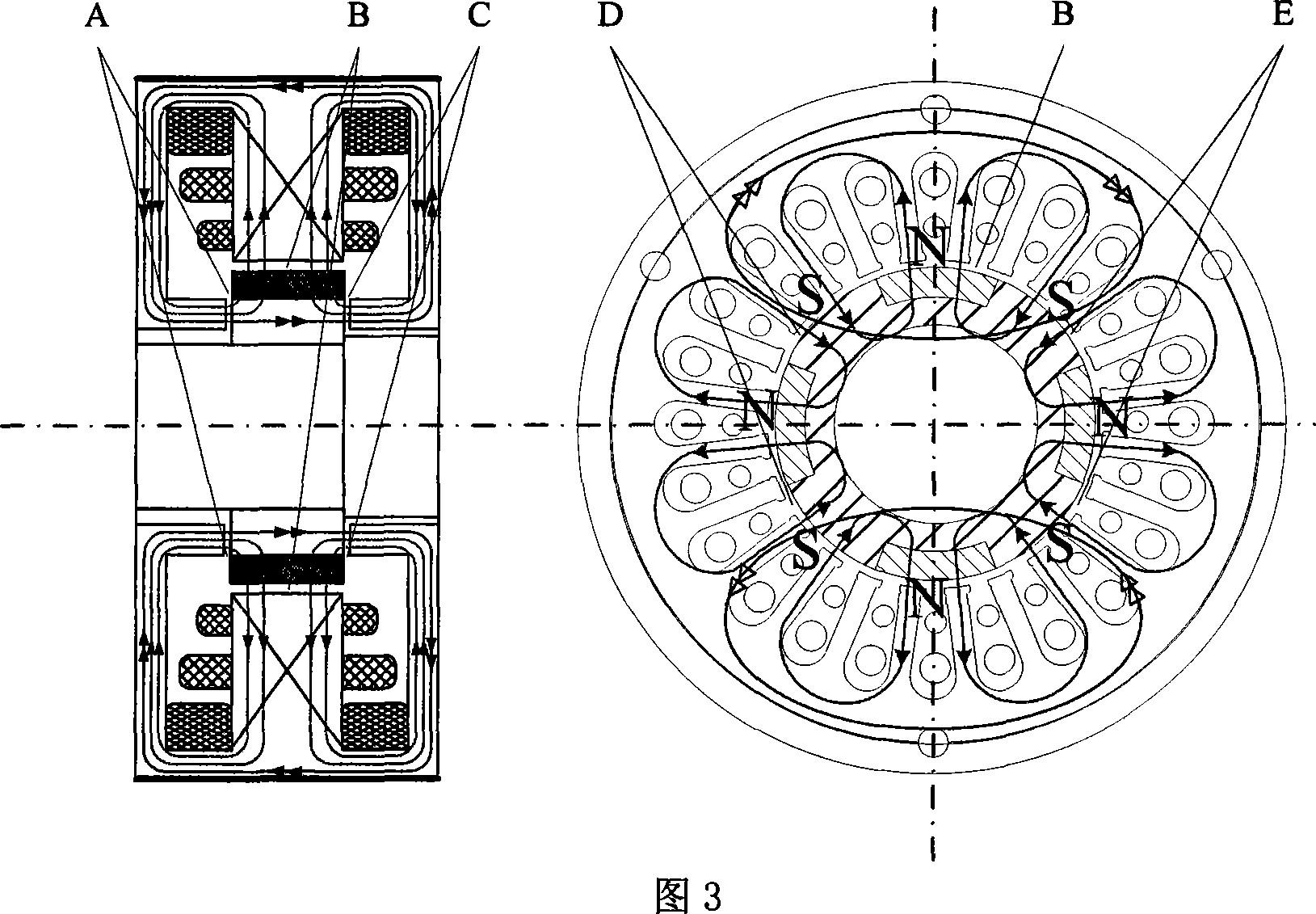

[0025] Fig. 1 and Fig. 2 are two-dimensional and three-dimensional schematic diagrams of the three-degree-of-freedom bearingless alternating pole permanent magnet motor with axial active suspension of the present invention, which mainly consists of an axial stator core 1, a radial stator core 2, and a rotor permanent magnet 3 , rotor core 4, rotor shaft 5 components. Among them, two axial stator cores 1 are processed by electrical pure iron, and are respectively installed on the left and right ends of the radial stator core 2. A set of axial suspension control windings 8 are respectively embedded and wound on the two axial stator cores 1. Two sets of axial suspension control windings 8 are connected in series. Both the radial stator core 2 and the rotor core 4 are made of laminated silicon steel sheets, and a set of three-phase four-pole torque control winding 7 for controlling the torque output of the motor is embedded and wound on the radial stator core 2, and a set for The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com