Three degrees of freedom bearingless alternating pole permanent magnet motor control system with axial active suspension

A permanent magnet motor and control system technology, applied in the field of physical engineering, can solve problems such as high control and complex air gap magnetic field, and achieve the effects of simple control method, small levitation current and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

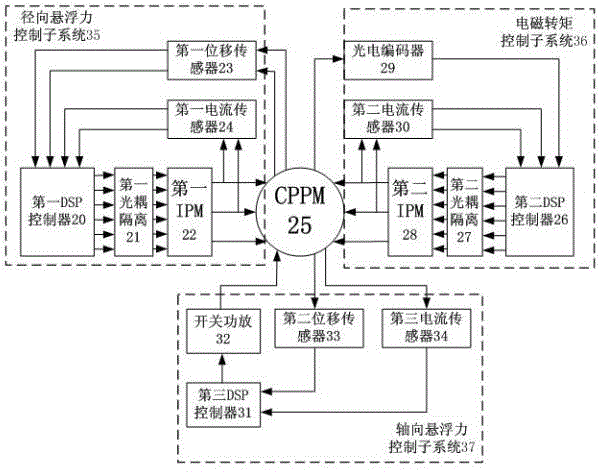

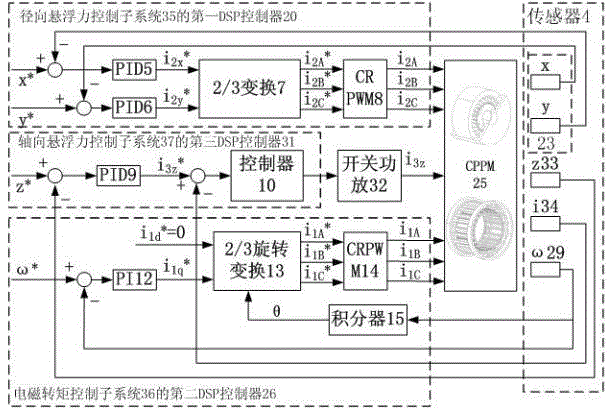

[0023] see figure 1 , the present axial active levitation three-degree-of-freedom bearingless alternating pole permanent magnet motor control system includes a controlled axial active levitation three-degree-of-freedom bearingless alternating pole permanent magnet motor (25), characterized in that: a radial The three-degree-of-freedom bearingless alternating pole permanent magnet motor with axial active suspension is connected to the suspension force control subsystem (35), an axial suspension force control subsystem (37) and an electromagnetic torque control subsystem (36) (25), wherein the radial suspension force control subsystem (35) includes a first DSP controller (20), a first optocoupler isolation (21), a first IPM intelligent power module (22), A first displacement sensor (23) and a first current sensor (24), the axially actively suspended three-degree-of-freedom bearingless alternating pole permanent magnet motor (25) passes through the first displacement sensor (23) ...

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0026]The axial suspension force control subsystem (37) includes a switching power amplifier (32), a second displacement sensor (33), a third current sensor (34) and a third DSP controller (31), the The three-degree-of-freedom bearingless alternating pole permanent magnet motor (25) and the third DSP controller (31) are connected to the switching power amplifier (32), the second displacement sensor (33) and the third current sensor (34) respectively in the axial active levitation ; The second displacement sensor (33) detects the rotor axial displacement offset through position negative feedback, uses the third DSP controller (31) to calculate and process to obtain the required control signal, and switches the power amplifier (32) to This control signal is converted into an axial suspension control current, which changes the magnetic field distribution in the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com