Magnetic suspension bearing and magnetic suspension centrifugal compressor and air conditioner

A magnetic levitation bearing and centrifugal compressor technology, applied in the field of compressors, can solve problems such as inconsistent axial displacement of the main shaft, excessive bearing controller, and collision of the main shaft, so as to improve control accuracy, critical speed and stiffness, and stability effect on reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

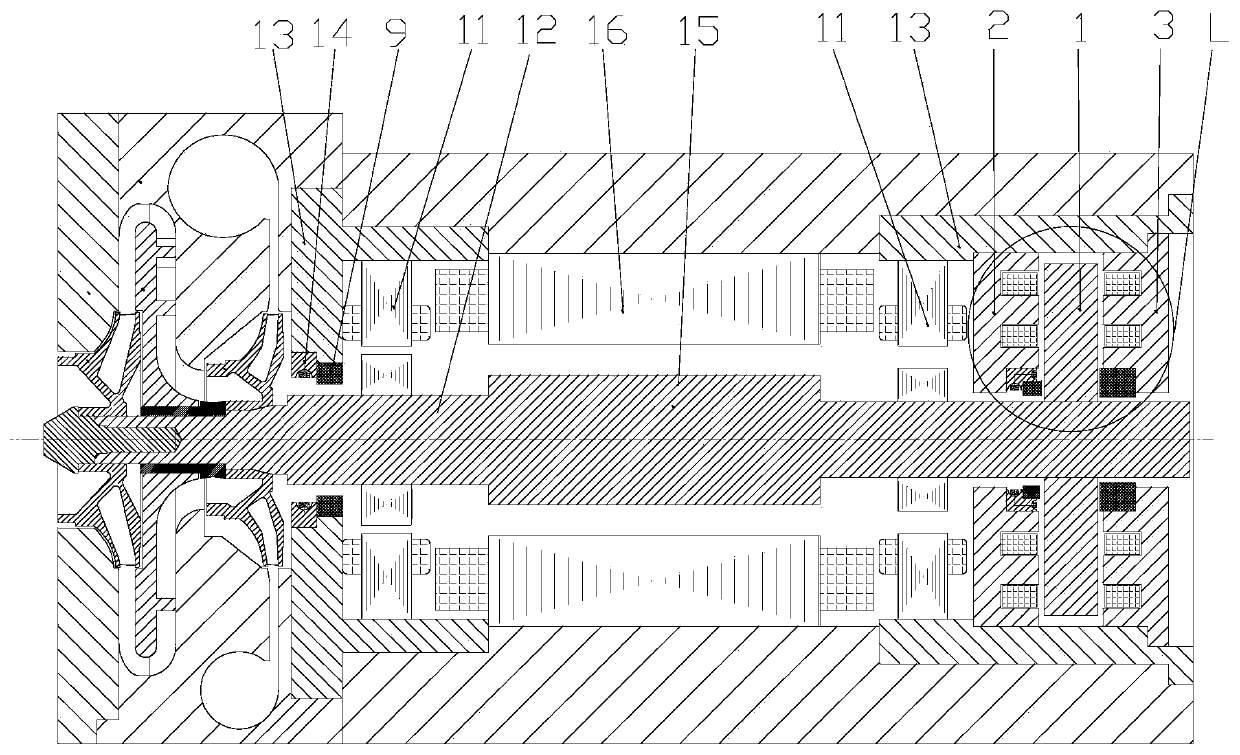

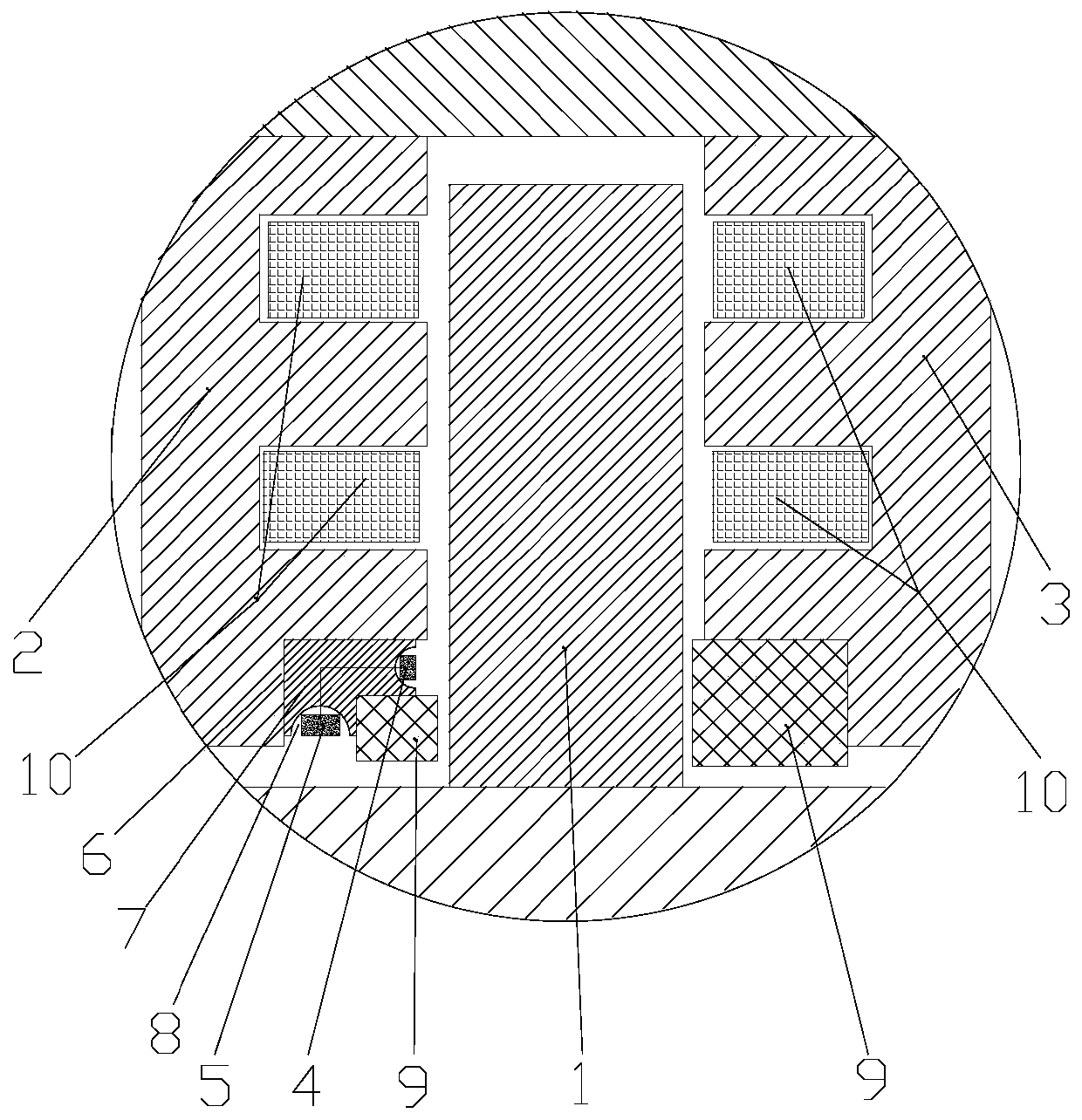

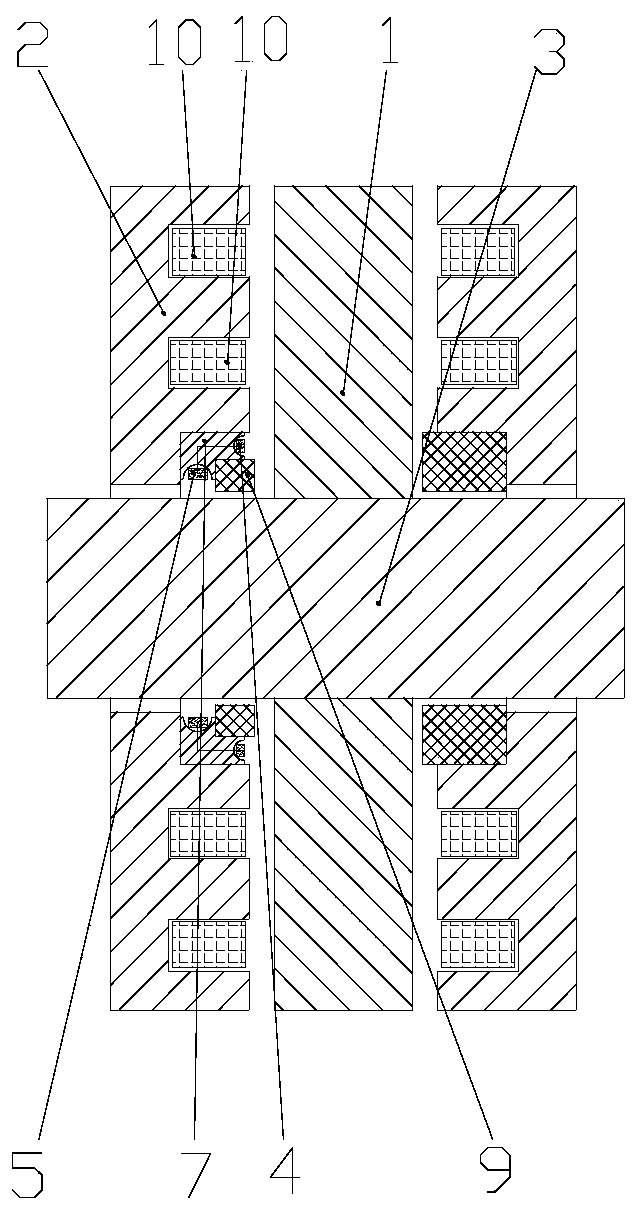

[0034] see in conjunction Figure 1 to Figure 4 As shown, according to the embodiment of the application, the magnetic suspension bearing includes an axial thrust bearing 1, a first axial bearing stator 2 and a second axial bearing stator 3, and the first axial bearing stator 2 and the second axial bearing stator 3 are arranged at both axial ends of the axial thrust bearing 1, used to adjust the axial position of the axial thrust bearing 1, the first axial bearing stator 2, the second axial bearing stator 3 and the axial thrust bearing At least one of the bearings 1 is provided with an axial displacement sensor 4 for detecting the axial displacement of the axial thrust bearing 1 .

[0035] In the magnetic suspension bearing of the present application, the axial displacement sensor 4 for detecting the axial displacement of the shaft 12 is arranged on at least one of the first axial bearing stator 2, the second axial bearing stator 3 and the axial thrust bearing 1 In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com