Low consumption permanent magnetism biased axial radial magnetic bearing

A permanent magnet offset, axial-radial technology, applied in the direction of shaft and bearing, bearing, shaft, etc., can solve the problems of long axial length of rotor, large eddy current loss, increased magnetic bearing loss, etc., and achieve high critical speed. , The effect of low bearing loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

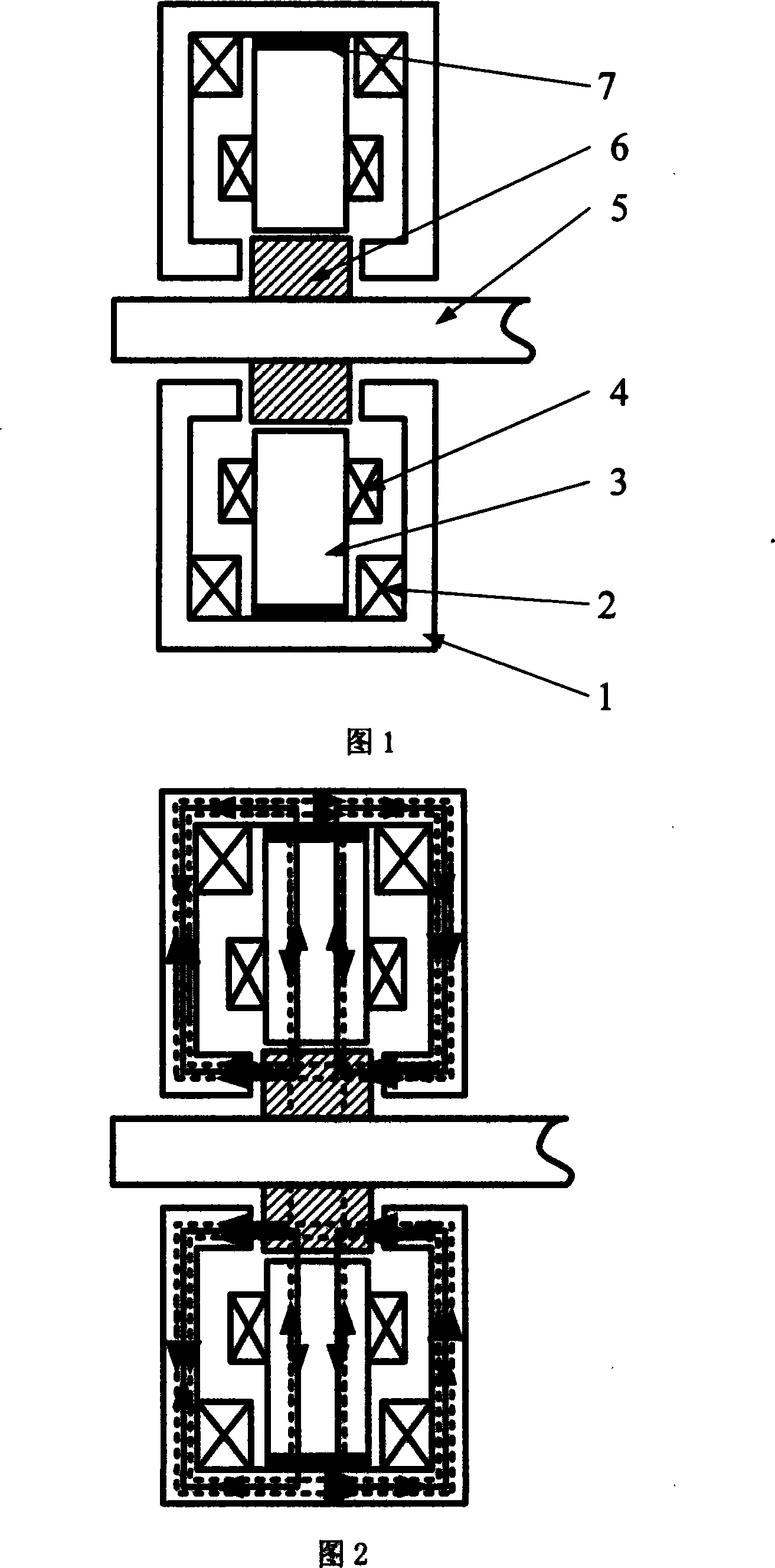

[0012] Fig. 1 is a schematic structural view of the low-loss permanent magnet bias axial radial magnetic bearing of the present invention, the axial stator pole 1 in the figure is made of electric iron, and two axial control windings 2 are sheathed on the axial stator pole. The control windings 2 are connected in series, the inner end surface of the axial stator is in contact with the annular permanent magnet 7, and the annular permanent magnet is mounted on the outer end of the radial stator 3, and the radial stator is a four-pole structure with no gaps between the magnetic poles. Silicon steel sheets are stacked, and each pole is wound with a control winding 4 respectively. The rotor core 6 is stacked by silicon steel sheets and is set on the rotor 5 and placed in the stator 1 and the stator 3 . The bias flux generated by the annular permanent magnet passes through the axial pole core, the rotor core, the radial air gap and the radial stator in turn to form a circuit, as show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com