Frequency modulation device for combustion gas turbine flame tube and combustion gas turbine flame tube

A gas turbine and flame tube technology, which is applied in the combustion chamber, combustion method, combustion equipment, etc., can solve the problems of complex combustion chamber structure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

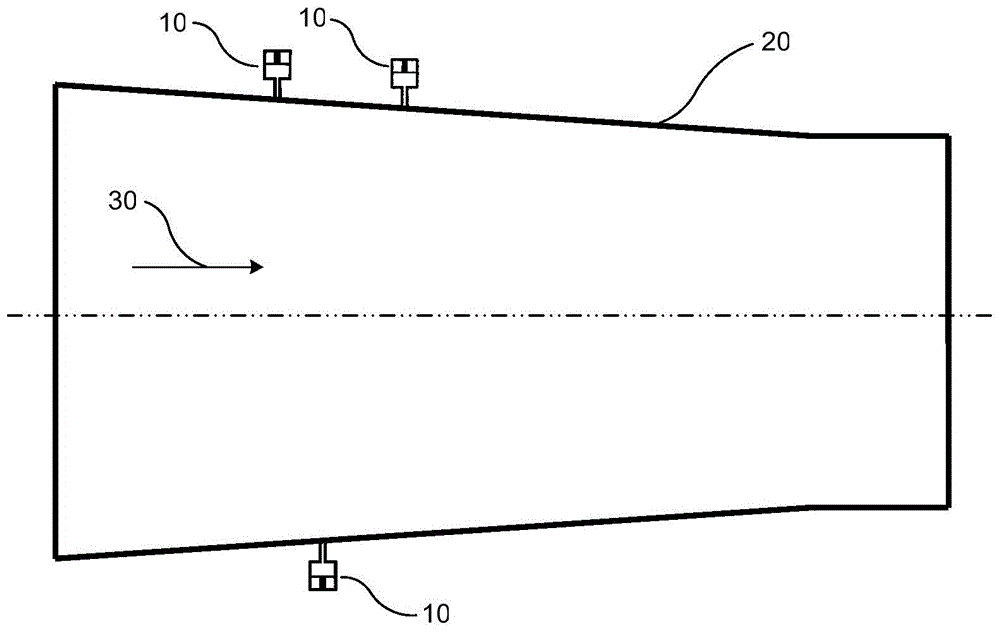

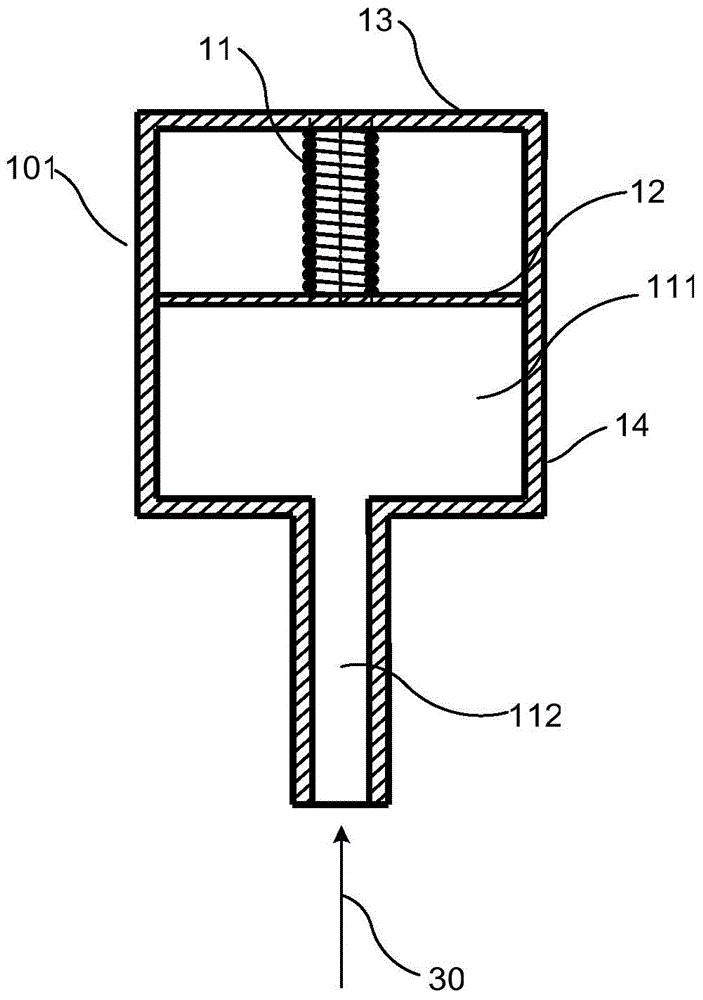

[0026] Such as figure 2 with image 3 As shown, a frequency modulation device 10 for a gas turbine flame cylinder provided by the present invention includes a device body, the device body is provided with a chamber, and the bottom of the chamber is provided with an opening for gas circulation, and the combustion gas flow 30 enters the chamber from the opening, the chamber is provided with an elastic element 11 and a partition 12 below the elastic element 11, the elastic element 11 can be various types of springs, one end of the elastic element 11 is connected to The top wall 13 of the chamber is connected, and the other end thereof is connected with the partition 12 , and there is a gap between the side of the partition 12 and the side wall 14 of the chamber. The frequency modulation device 10 is an acoustic chamber that oscillates the pressurized fluid at a specific frequency. The geometric configuration of the frequency modulation device 10 is directly related to the frequ...

Embodiment 2

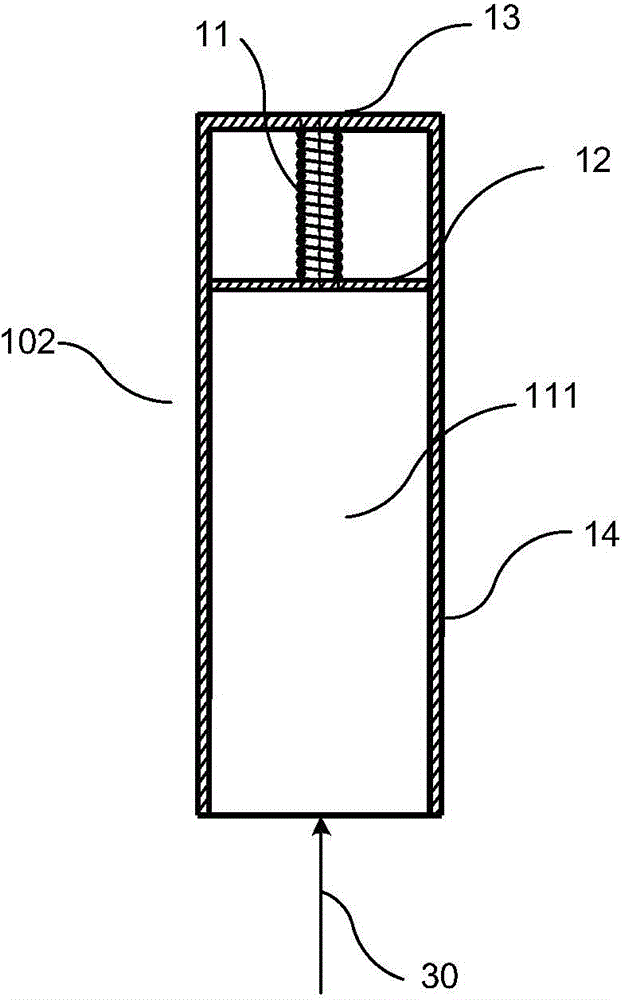

[0034] The difference between this embodiment and Embodiment 1 is that the device body uses a quarter-wavelength tube resonator 102, such as image 3 As shown, the quarter wave tube resonator 102 has a body cavity 111 . The relationship between the resonant frequency f of the quarter-wavelength tube resonator 102 and its geometric parameters is as follows:

[0035] f = c 4 L

[0036] where c is the speed of sound in a fluid (eg, air, fuel, or diluent) and L is the length of the quarter-wave tube resonator 102 . It can be seen that the quarter wave tube resonator 102 can attenuate frequencies corresponding to wavelengths four times its length L. FIG.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com