Device based on electron beam hot wire fuse additive manufacturing

An additive manufacturing and electron beam technology, applied in the field of additive manufacturing, can solve problems such as reducing the overall performance of parts, reducing mechanical properties of parts, and microstructure inhomogeneity, reducing substrate deformation, changing stress distribution, and achieving excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

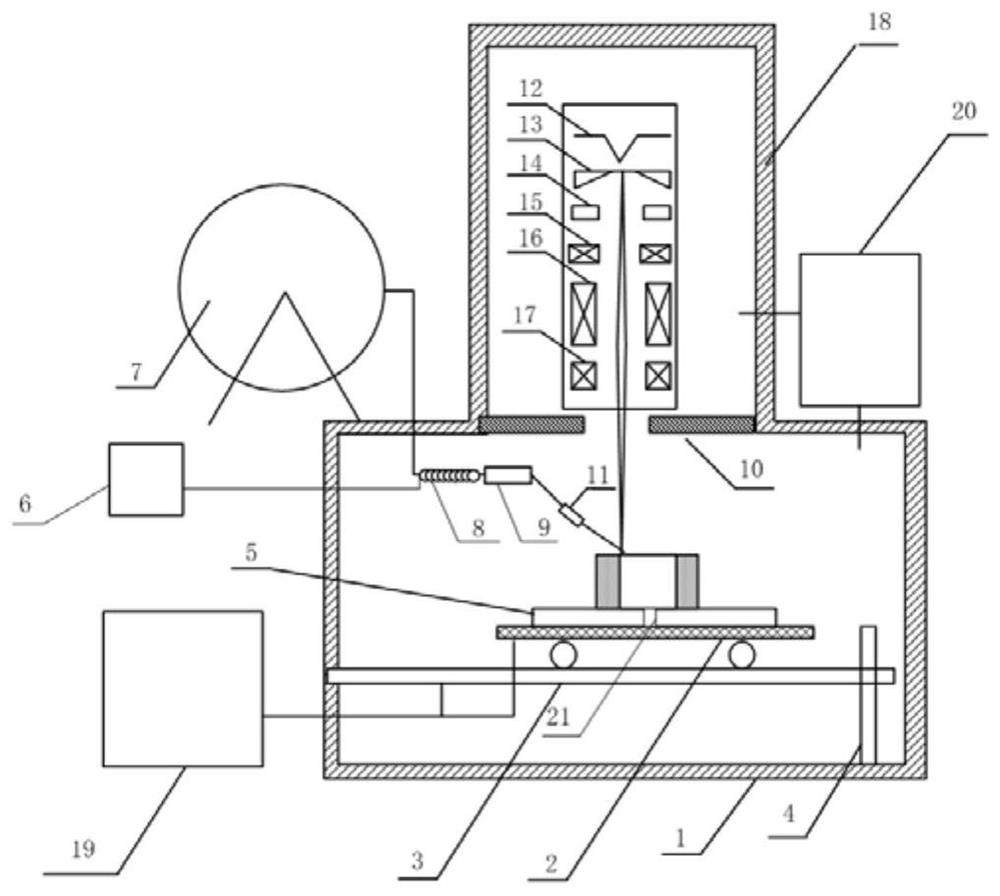

[0024] A device based on electron beam hot wire fuse additive manufacturing, the device includes an electron gun, a wire feeding system, an electron gun vacuum chamber, a vacuum forming chamber 1, a working displacement platform 2, a resistance heating system, and a servo control system 19, the described The electron gun comprises the filament 12 that produces electron beam, the cathode 13 below the filament, the grid 14 below the cathode, the anode 15 below the grid, the focusing coil 16 below the anode and the deflection coil 17 below the focusing coil. In the chamber 18; the electron gun vacuum chamber 18 is placed on the top of the vacuum forming chamber 1, and is communicated with and isolated from the vacuum forming chamber 1 through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com