fgb submerged arc single side welding and double side forming welding process

A single-sided welding double-sided, welding process technology, applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve the problems of difficult to guarantee welding quality, low efficiency, welding quality depends on welders, etc., to improve welding efficiency and on-site operation Simple and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

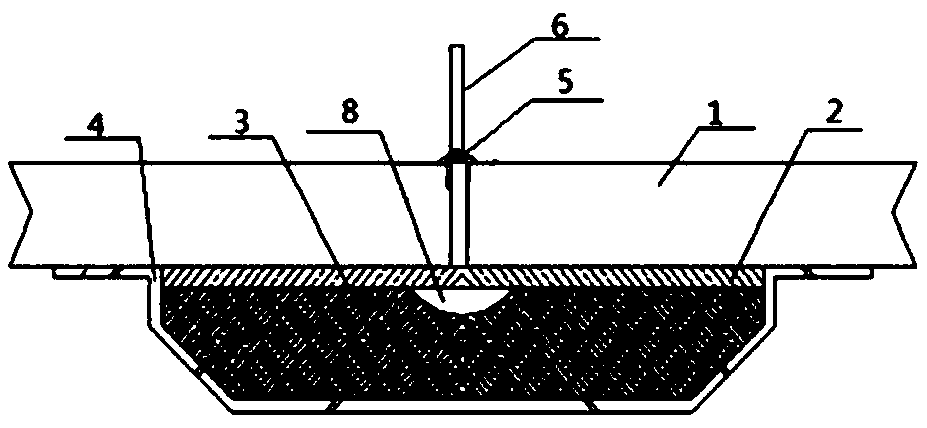

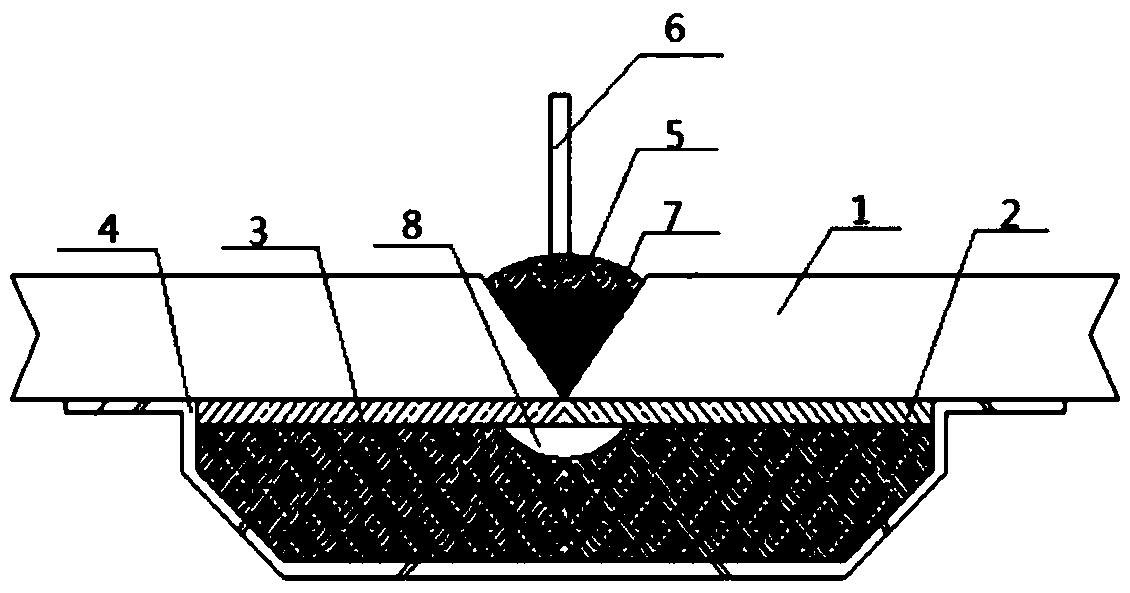

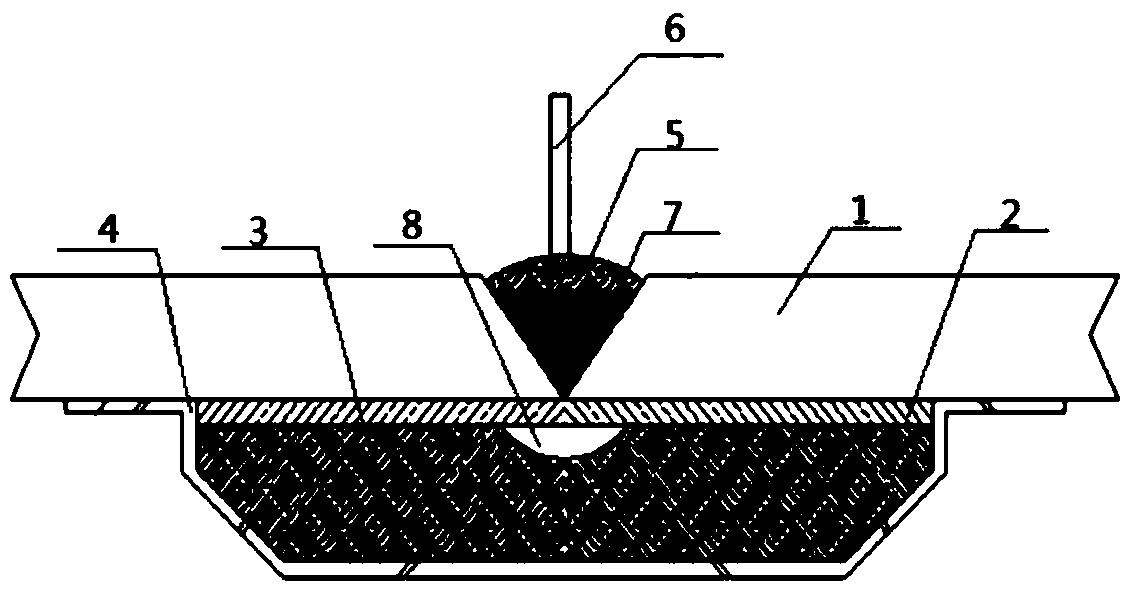

[0026] Such as figure 1 As shown, the present invention provides a kind of FGB submerged arc single-sided welding double-sided forming welding process, comprising the following steps:

[0027] S1. Use a grinder to grind two steel plates with a thickness of 6mm to be welded to give a metallic luster to the groove and the parts with a width of 20mm on both sides of the groove. Wipe the polished place with absorbent paper or a dry rag to remove moisture or dust. Layer, etc., butt the two polished steel plates 1 to form an I-shaped groove with a gap of 0 mm, and control the staggered side and hypotenuse of the two steel plates 1 to be 0 mm;

[0028] S2. On the bottom surface of the groove, paste a glass fiber cloth 2 with a width of 50 mm and a thickness of 0.8 mm centering on the center line of the groove, and repeatedly scrape and press the ceramic liner block 3 along the direction parallel to the groove, so that The glass fiber cloth 2 is closely attached to the bottom surface...

Embodiment 2

[0031] Such as figure 1 As shown, the present invention provides a kind of FGB submerged arc single-sided welding double-sided forming welding process, comprising the following steps:

[0032] S1. Use a grinder to polish two pieces of steel plates to be welded with a thickness of 6mm to give a metallic luster to the groove and the parts within the width of 15-30mm on both sides of the groove. Wipe the polished place with absorbent paper or a dry rag to remove Moisture or ash layer, etc., butt the two polished steel plates 1 to form an I-shaped groove with a gap of 1 mm, and detect the misalignment and hypotenuse of the two steel plates 1 to be welded to be 2 mm;

[0033] S2. On the bottom surface of the groove, paste a glass fiber cloth 2 with a width of 50 mm and a thickness of 1.5 mm centering on the center line of the groove, and repeatedly scrape and press the ceramic liner block 3 along the direction parallel to the groove, so that The glass fiber cloth 2 is closely atta...

Embodiment 3

[0036] Such as figure 1 As shown, the present invention provides a kind of FGB submerged arc single-sided welding double-sided forming welding process, comprising the following steps:

[0037] S1. Use a grinder to grind the two steel plates to be welded with a thickness of 12mm to give a metallic luster to the groove and the parts within the width of 15-30mm on both sides of the groove, and wipe the polished place with absorbent paper or dry rag to remove Moisture or dust layer, etc., butt the two steel plates to be welded 1 after grinding to form an I-shaped groove with a gap of 0mm, and control the staggered side and hypotenuse of the two steel plates to be welded 1 to be 0mm;

[0038] S2. On the bottom surface of the groove, paste a glass fiber cloth 2 with a width of 50 mm and a thickness of 1.0 mm centering on the center line of the groove, and repeatedly scrape and press the ceramic liner block 3 along the direction parallel to the groove, so that The glass fiber cloth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com