Gas protection device for laser-arc hybrid welding and laser-arc hybrid welding machine

A gas shielding device, laser arc technology, applied in arc welding equipment, laser welding equipment, jetting device and other directions, can solve the problem that the shielding gas flow rate cannot be too high, cannot effectively suppress the plasma laser shielding effect, etc., to protect the forming quality , excellent scalability, the effect of large jet flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

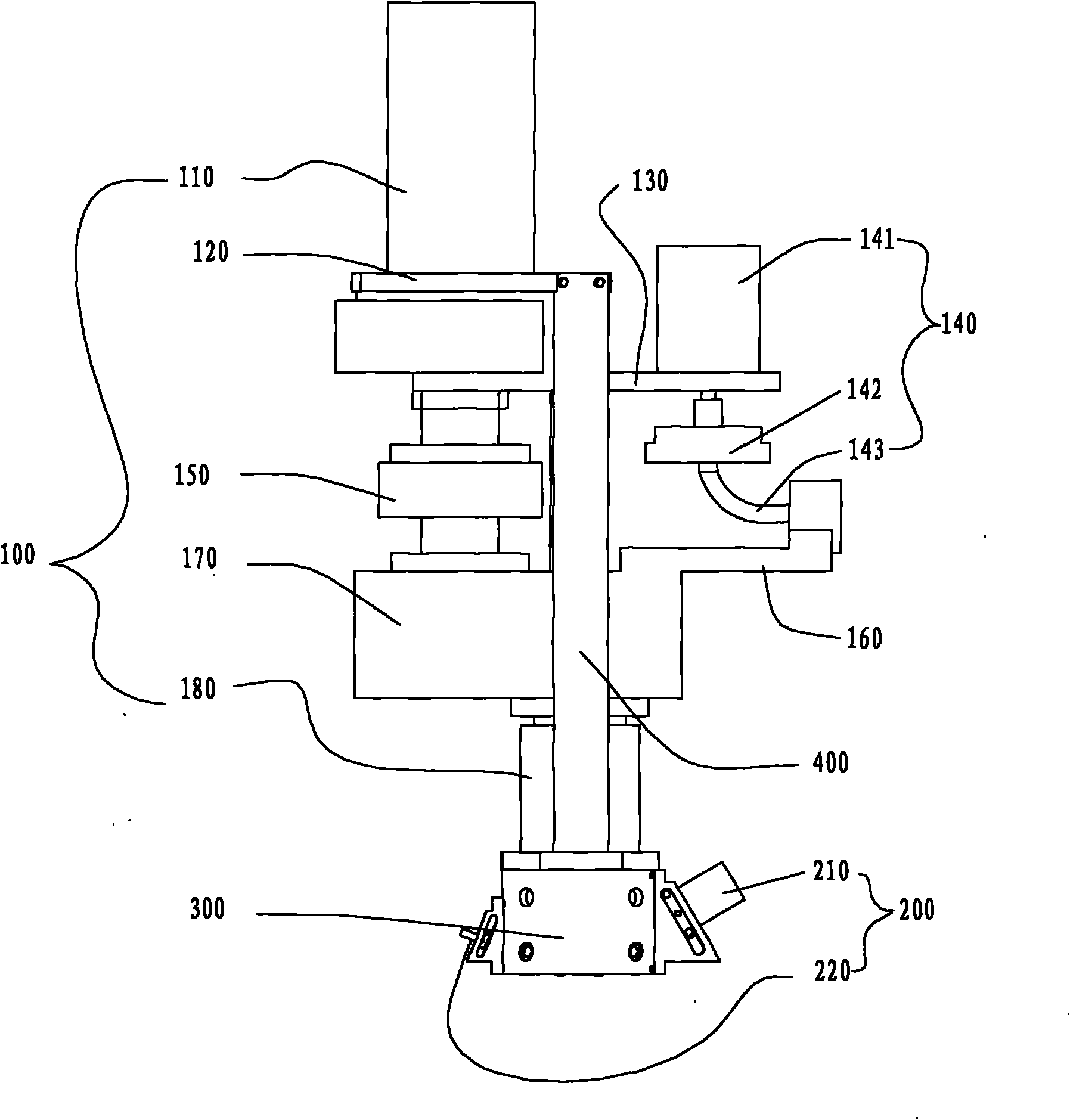

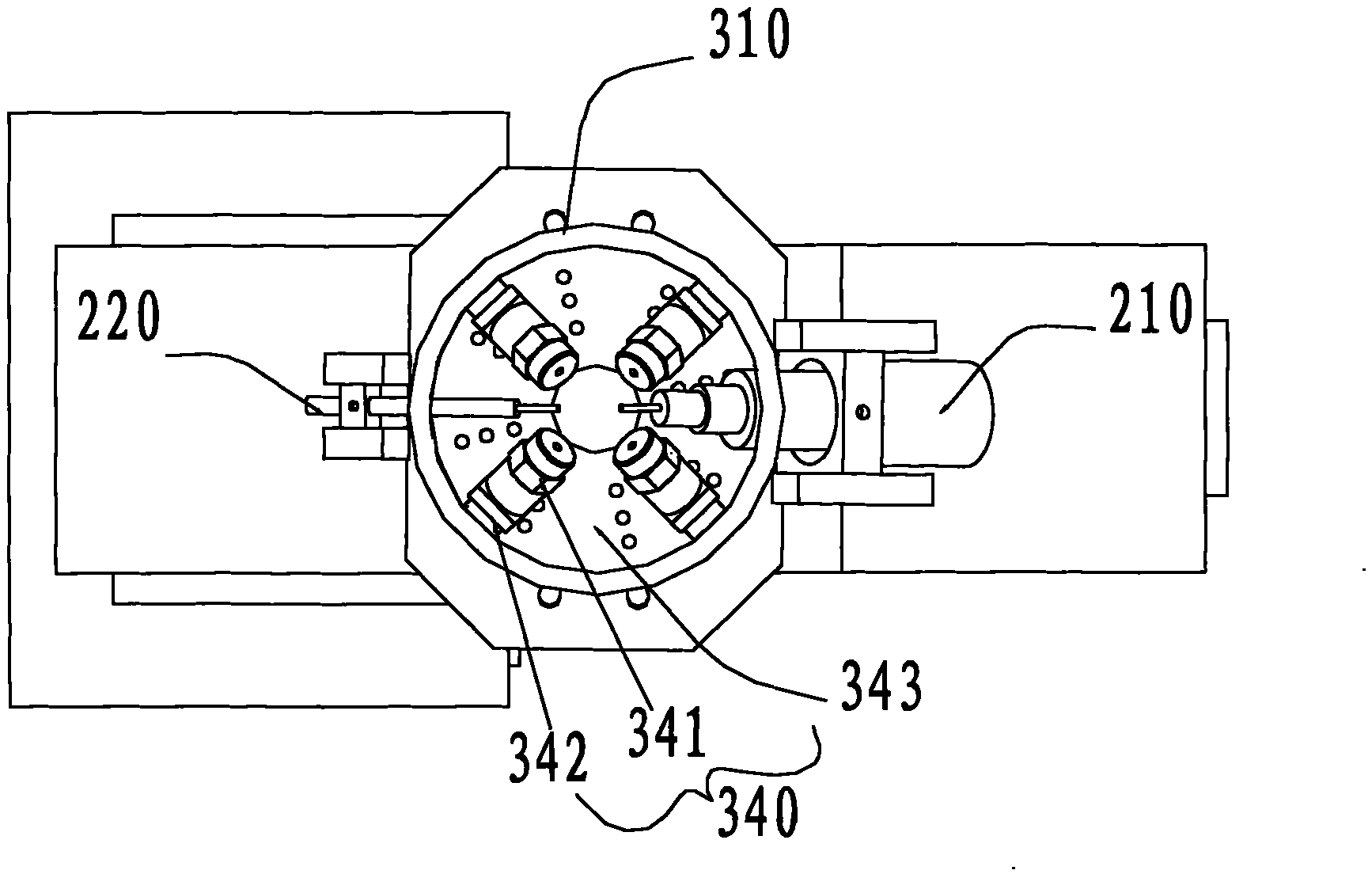

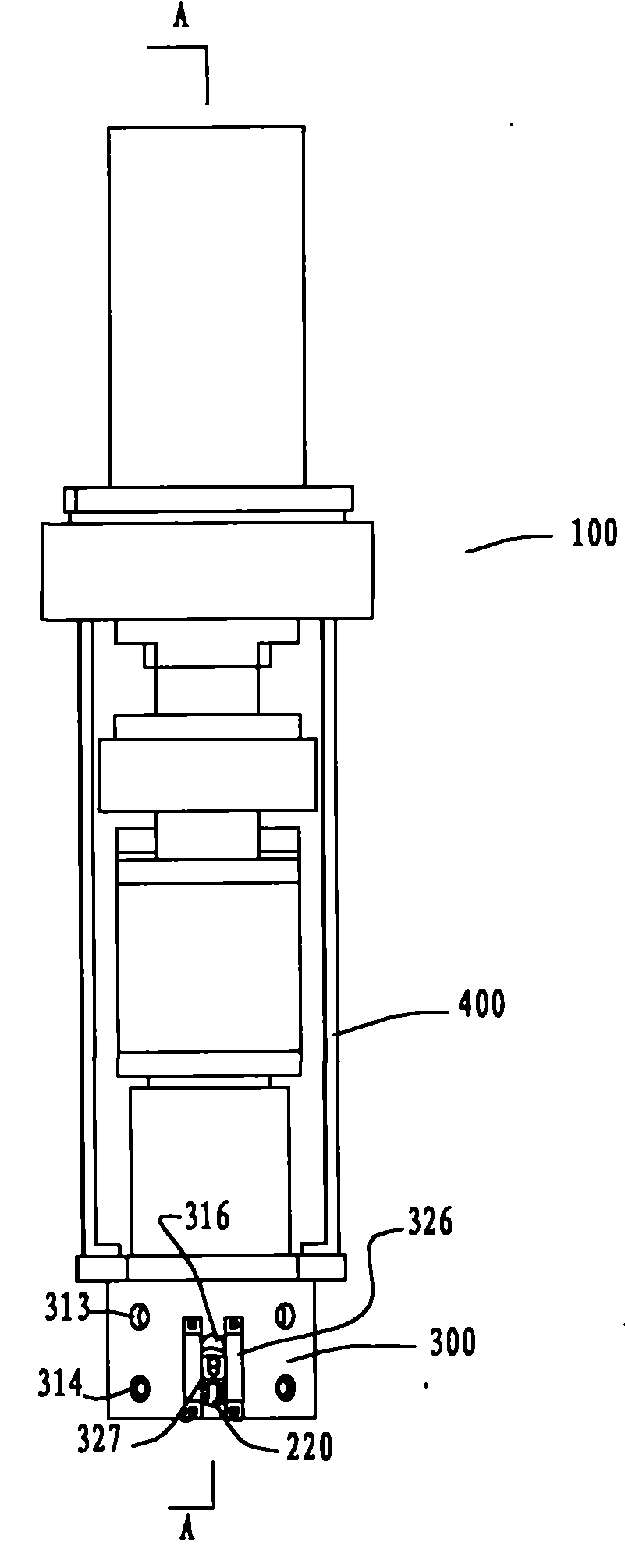

[0073] Figure 1 ~ Figure 4 Shown is the laser-TIG hybrid welding machine of the present invention, wherein figure 1 It is a schematic diagram of the front structure of the laser-TIG hybrid welding machine of the present invention. figure 2 yes figure 1 bottom view. image 3 yes figure 1 left view of . Figure 4 yes image 3 A-A cutaway view.

[0074] Such as Figure 1 ~ Figure 4 As shown, the laser arc hybrid welding machine includes a laser head 100 and an arc welding device 200, and it also includes a gas protection device 300, and the connection end 311 of the gas protection device 300 is connected to the bottom of the laser head 100, The arc welding device 200 is installed on the arc welding device installation part 320 . The laser head 100 and the gas protection device 300 are connected and fixed to each other through the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com