Metal shield

A metal mask and mask technology, applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve the problems of flatness change, influence on liquid crystal molecules, surface wrinkles, etc., and reduce the occurrence of wrinkles. situation, changing stress distribution, and improving the effect of production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

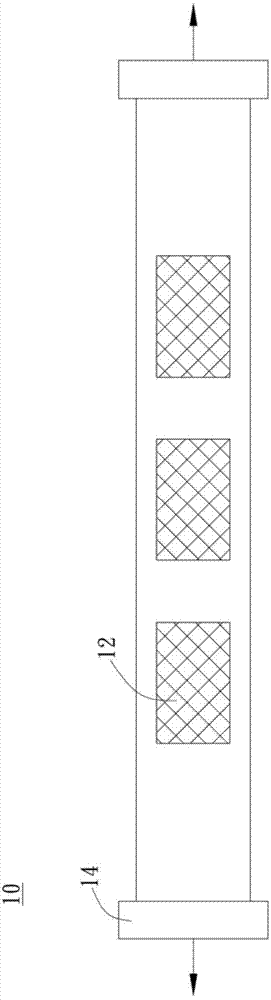

[0034] The metal mask of the present invention makes the metal mask have different thickness distributions by forming recesses on the surface, and at the same time reduces the stress when the metal mask is stretched, thereby reducing the occurrence of wrinkles. The metal mask of the present invention can preferably be used in the vapor deposition manufacturing process of organic light emitting diode displays

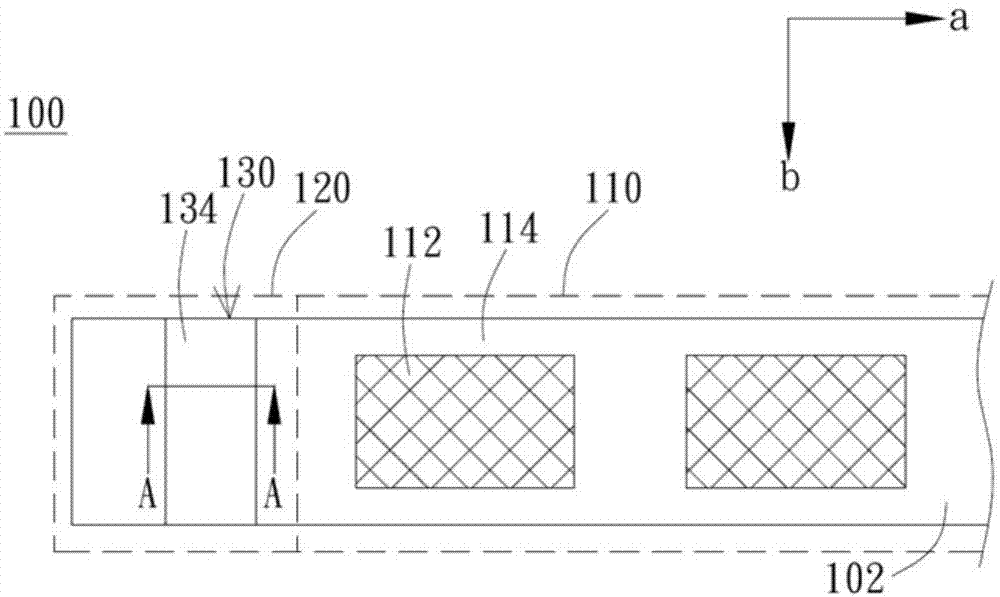

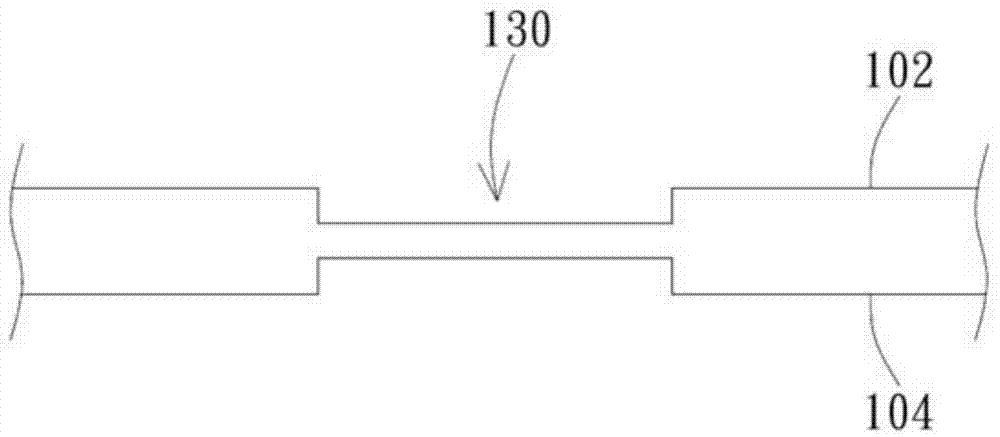

[0035] Figure 2A It is a top view of the metal mask 100 of the present invention. like Figure 2A As shown, the metal mask 100 includes a mask section 110 and an end section 120 . The mask section 110 refers to the middle section of the metal mask 100 , including several mask bodies 112 and an outer frame portion 114 surrounding and connecting the mask bodies 112 . The part of the mask body 112 corresponding to the substrate during evaporation. The metal mask 100 can have a plurality of mask sections 110 and adjust the number of required mask bodies 112 according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com