Memory alloy wire and fiber mixed weaving process

A technology of memory alloy wire and alloy wire, which is applied in braids, metal layered products, textiles and papermaking, etc., can solve the problem of light weight, intelligent service, material reduction, rigidity and other inherent characteristics that cannot meet working conditions and performance Failure to meet requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

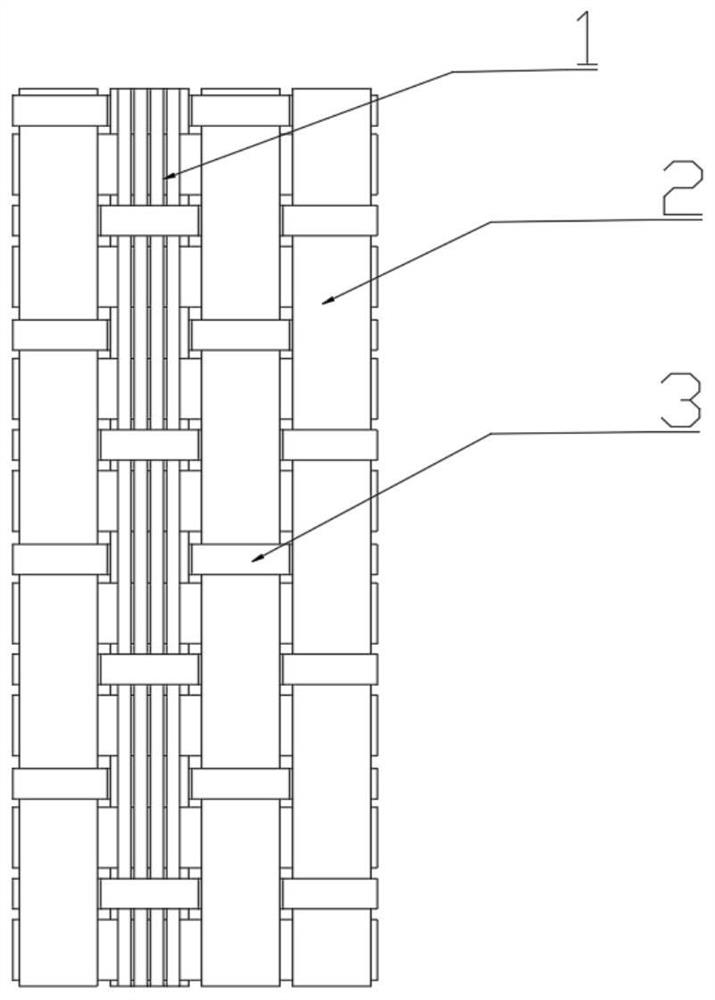

[0039] The selected nickel-titanium shape memory alloy wire 1 has a titanium content of 49.6-56%, the fibers are basalt fiber 2 and Kevlar fiber 3, the thermosetting resin is epoxy resin, and a three-dimensional braiding machine is used in an environment below the phase transition temperature. , choose the layer-by-layer orthogonal method, as shown in the figure, weave the shape of a rectangular parallelepiped.

[0040] Shape memory alloy wire Alloy wire 1 is woven with warp / weft yarn. In order to avoid the neutral layer of the fabric, the shape memory alloy wire is arranged on the surface layer of the fabric, and Kevlar fiber 3 is mainly woven as a knot yarn. In the process of doubling the alloy wire, a doubling machine can be used to wind the alloy wire on the spindle. During the winding process, a certain number of pulleys can be used to provide sufficient tension on the shape memory alloy wire.

[0041] When threading, the bending of the alloy wire should be avoided as muc...

example 2

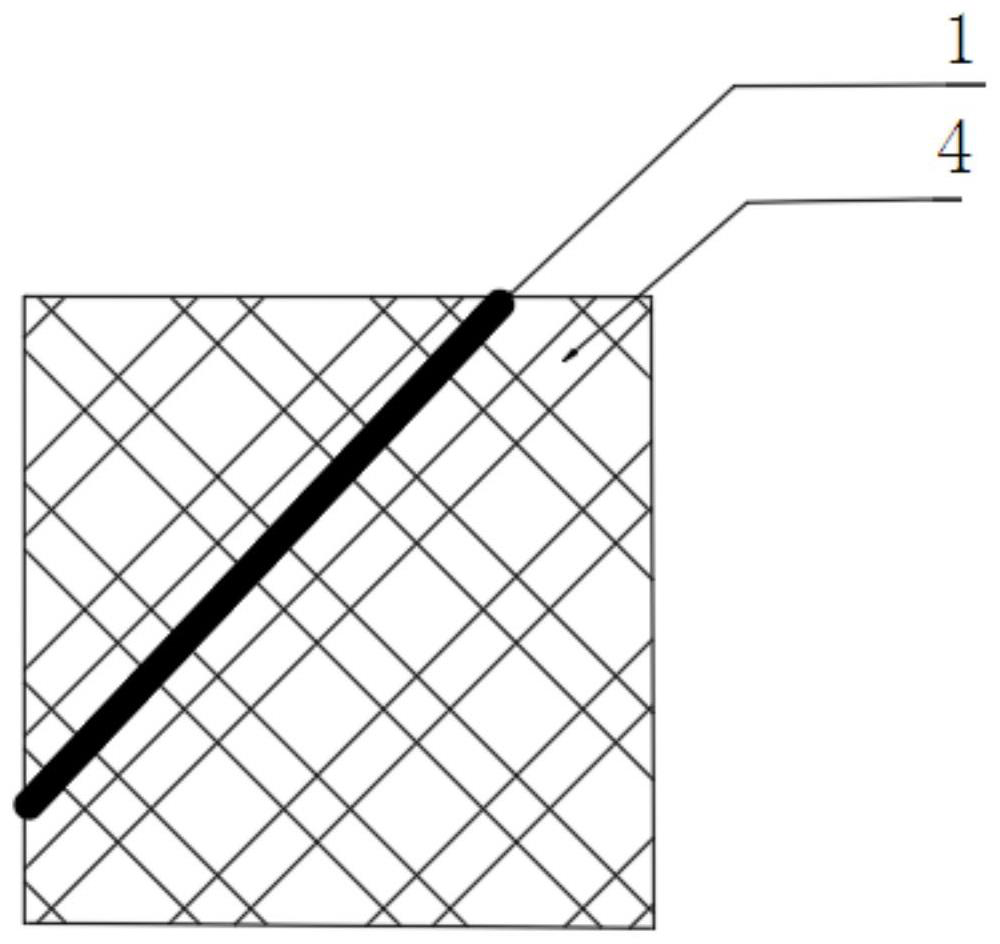

[0048] The nickel-titanium shape memory alloy wire 1 with a diameter of 0.4 mm is used, the carbon fiber 4 is used for the fiber, and the epoxy resin is used for the thermosetting resin.

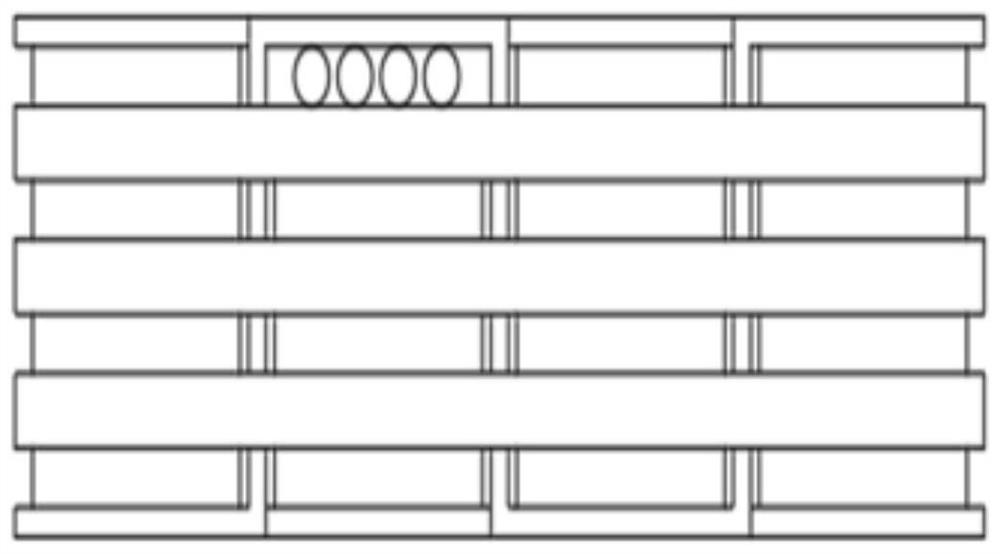

[0049] A number of shape memory alloy wires are inserted into the braiding machine, and the shape memory alloy wires are evenly arranged on the spindles of the annular radial braiding machine to be braided into the shape of a round tube. A mandrel is inserted into the fabric to hold the shape of the tube, and a layer of wax is applied to the tube so that it can be easily removed after curing.

[0050] Since the friction force of alloy wire is greater than that of fiber, in order to make alloy wire better woven into the spindle, the speed of the spindle should be fast and slow to ensure that the alloy wire does not damage the structure of the fiber. If necessary, the start and stop of the machine can be adjusted manually.

[0051] The braided braided fabric is put into a vacuum bag to be evac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com