Bearing ring having opening grooves, and bearing

A bearing ring and bearing technology, applied in the field of bearing rings, can solve the problems of failure of the axle box and reduction of the service life of the bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

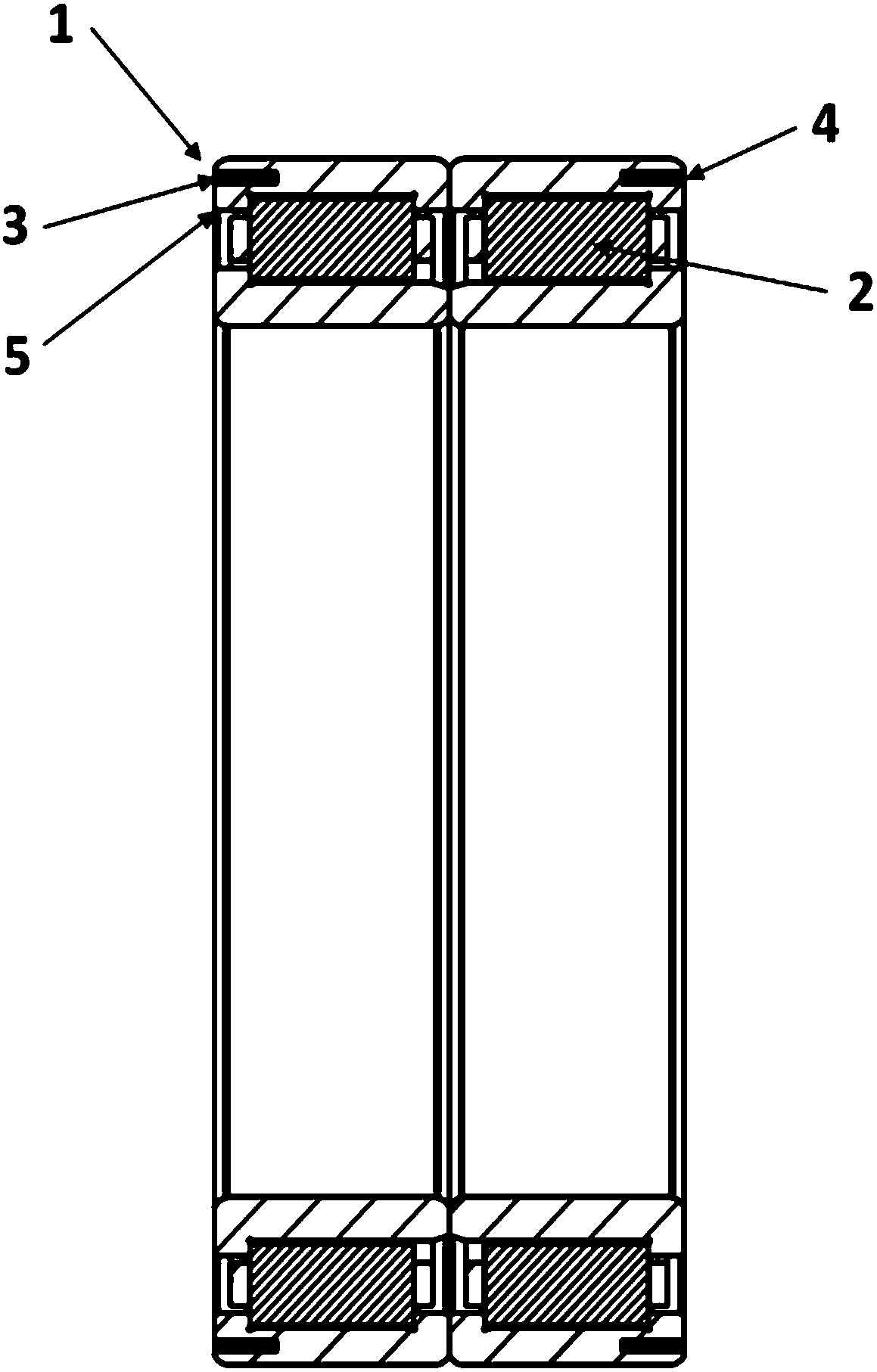

[0016] in figure 1 A bearing ring designed according to an embodiment of the invention is shown in. Here, the bearing ring is designed as a bearing outer ring 1. The bearing outer ring 1 is basically the same as the bearing outer ring of the rolling bearing in the prior art, that is, it has a circular ring shape and is composed of two radially extending end surfaces and an outer surface and an inner surface extending in the axial direction. Such as figure 1 As shown, shoulders 5 are respectively provided at the positions where the inner surface and the two end surfaces meet, which are used to limit the rolling elements 2 to the raceway area and act as an axial stop. When the bearing bears an axial load, the stop The shoulder can also carry axial forces. The inner surface between the two shoulders 5 is provided as a rolling surface for the rolling elements.

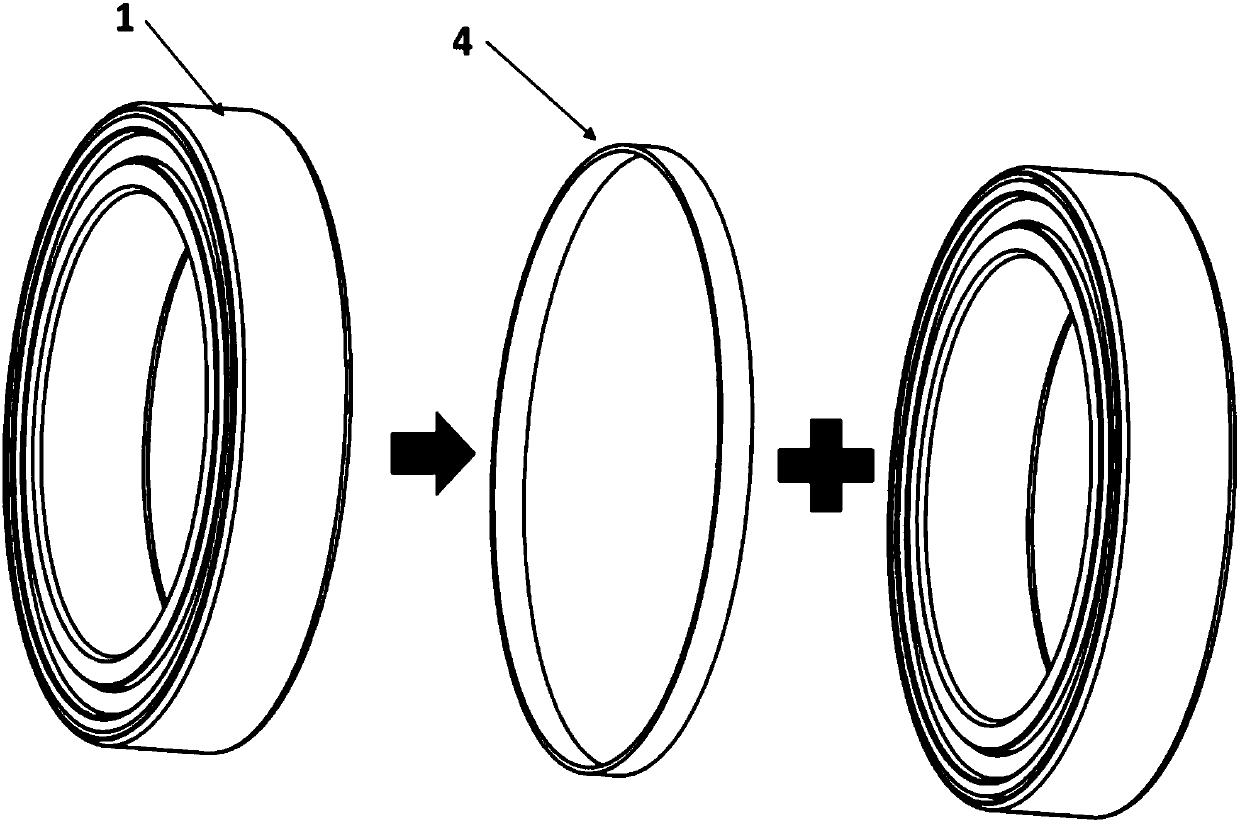

[0017] The difference between the bearing outer ring 1 designed according to the embodiment of the present invention and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com