Waste mercury recovery and purification device and use method thereof

A liquid storage and control mechanism technology, which is applied in the field of new waste mercury recovery and purification devices, can solve the problems of no professional organization for door-to-door recovery, complex production process, dangerous transportation, etc., and achieves the effects of light weight, reduced inventory rate, and expanded application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

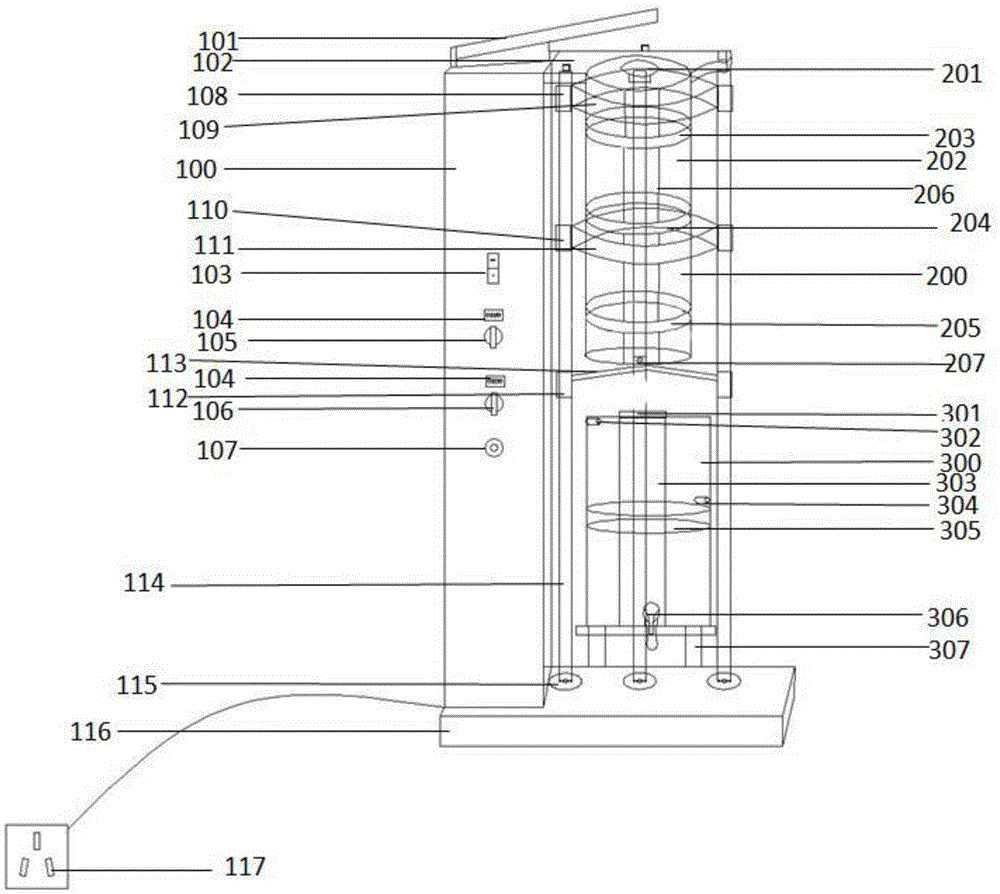

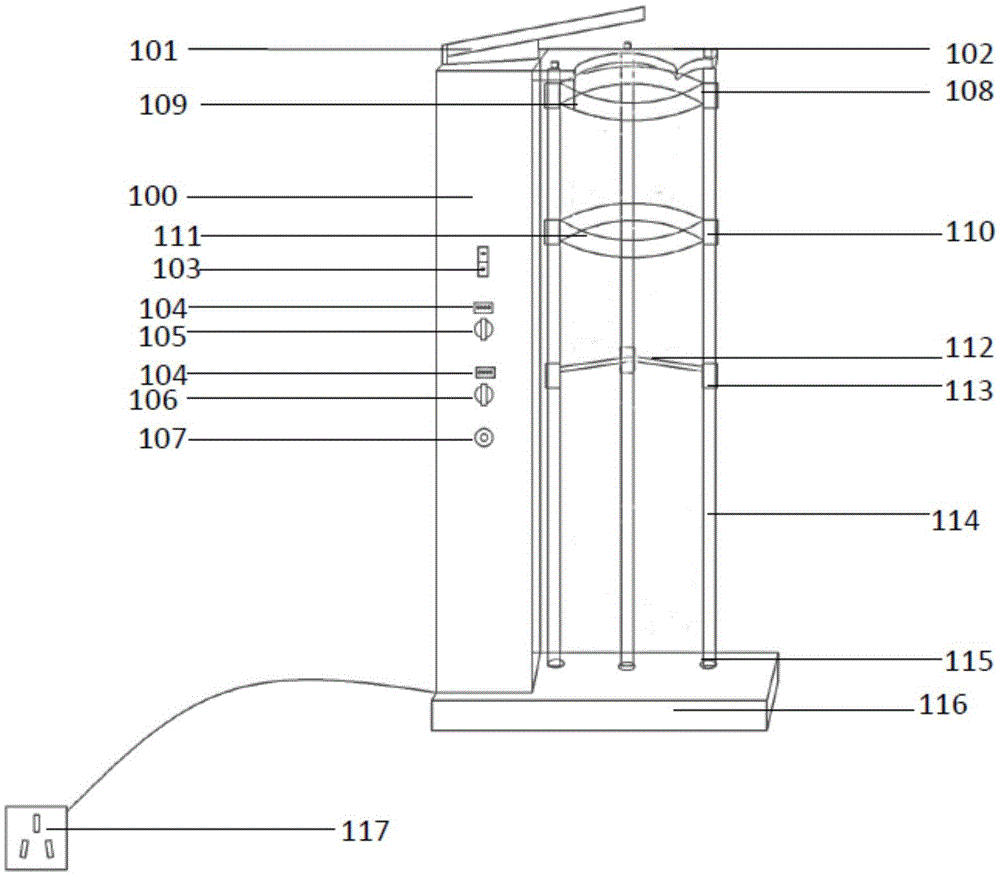

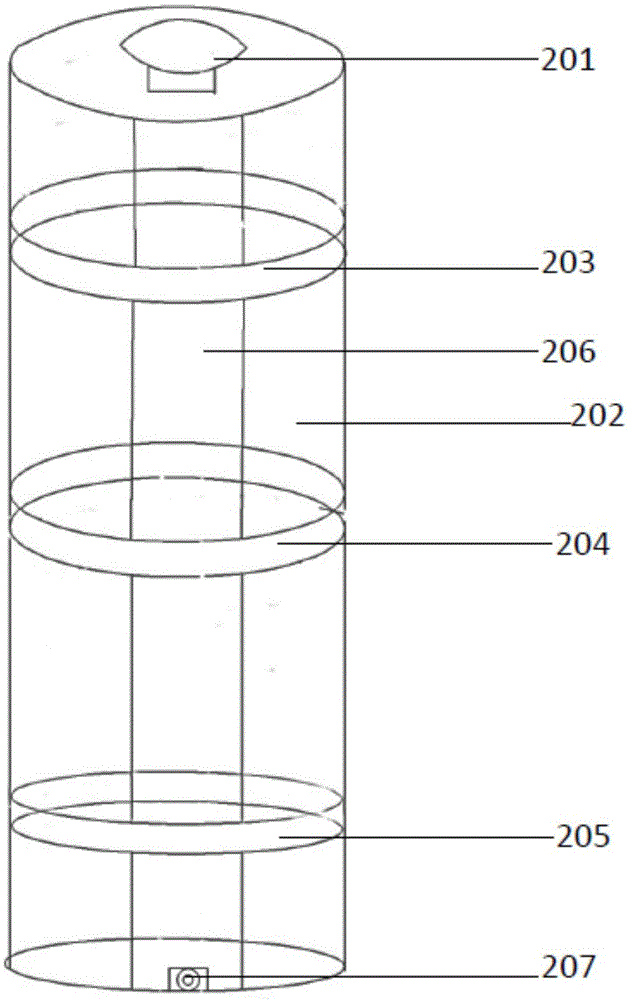

[0033] like Figure 1-4 As shown, the waste mercury recovery and purification device of the present invention includes a control mechanism 100, a vibrating screen mechanism 200 and a filtering liquid storage mechanism 300;

[0034] The control mechanism 100 includes a striker 101 and a fixed platform 102 arranged at the bottom of the striker 101. The surface of the control mechanism 100 is provided with a switch 103, a liquid crystal display screen 104, a working frequency knob 105, a working time setting knob 106 and an emergency stop in parallel. Switch 107, two integral fixing rods 114 are fixed in parallel at the bottom of the fixed platform 102. The integral fixing rods 114 are connected by the upper fixing clamp 109, the middle fixing clamp 111 and the bottom support rod 113, the upper fixing clamp 109, the middle fixing clamp 113 The fixing clamp 111 , the bottom support rod 113 and the integral fixing rod 114 are respectively fixed by the upper fixing part 108 , the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com