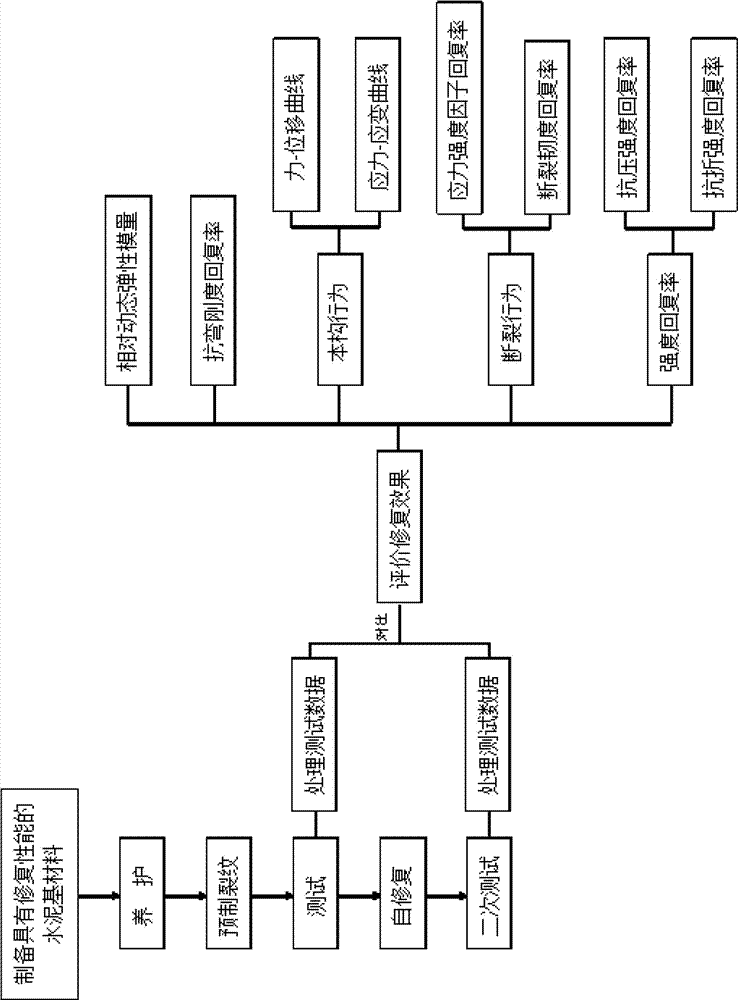

Self-healing effect evaluation method of self-healing cement-based materials

A technology for cement-based materials and evaluation methods, which is applied in the application of stable tension/pressure to test the strength of materials and the preparation of samples for testing, which can solve the lack of direct improvement in material stiffness, toughness, impermeability, erosion resistance and durability. Effective evaluation methods, single repair efficiency evaluation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

[0096] Both Examples 1 and 2 use microcapsule self-healing cement-based materials.

[0097] Firstly, microcapsules with self-healing properties were prepared. The ratio of the mass of the microcapsule particles to the total mass of the finished microcapsule (ie, the microcapsule emulsion system) is the solid content of the microcapsule. The solid content of the microcapsules in Examples 1 and 2 is 40%. The ratio of raw materials is as shown in Table 1:

[0098] Table 1:

[0099] raw material

[0100] potassium persulfate

[0101] The preparation process is as follows:

[0102] (1) take each component material by proportioning;

[0103] (2) Add the epoxy resin diluted with benzyl alcohol as a diluent into a bucket container, stir and dilute;

[0104] (3) Sodium dodecylbenzene sulfonate is used as emulsifier, and octylphenylpolyethylene oxide is used as surfactant, both are mixed with deionized water, after stirring and dispersing for 8 minutes, join in ...

test approach 1

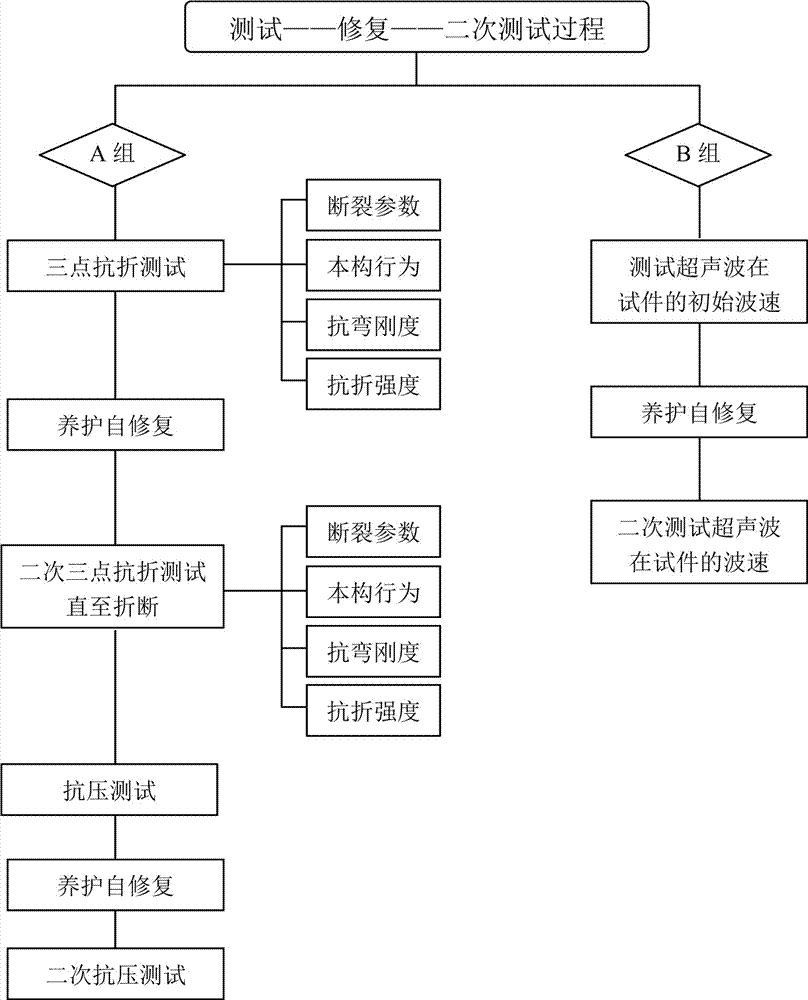

[0113] The test method of embodiment 1 and 2 is consistent, and concrete steps are as follows:

[0114] (1) prepare sample according to sample preparation scheme described in the present invention, each test group prepares 9 specimens, wherein 3 specimens are used for testing reference strength, and other 6 specimens are used for setting different degrees of pre-destruction;

[0115] (2) After the test piece reaches its age, cut a crack with a length of 40mm, a width of 0.5mm, and a depth of 10mm on the side;

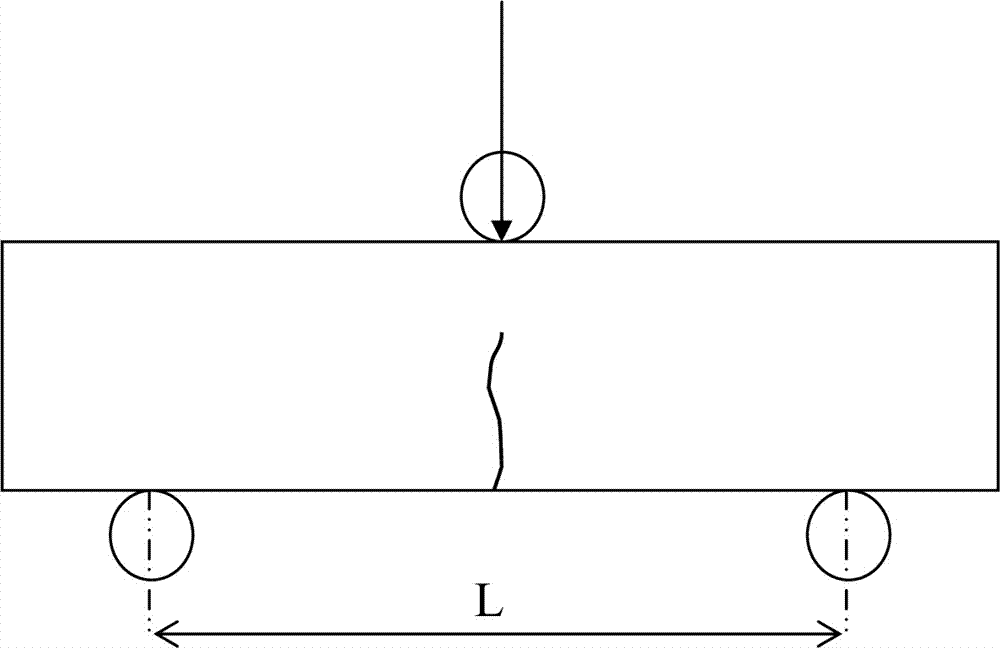

[0116] (3) Carry out three-point flexural tests on 3 test pieces of each test group, measure the flexural strength of the samples under different curing conditions with different dosages, and take the average value of the three test data for the final data;

[0117] (4) Carry out different degrees of pre-destruction to the other 6 specimens of each test group according to the method provided in the technical scheme, that is, the aforementioned summary of the invention, ...

Embodiment 3 and 4

[0133] Examples 3 and 4 both use mineral self-healing cement-based materials.

[0134] Both Examples 3 and 4 use a 40mm×40mm×160mm concrete test block to characterize the change of the internal damage degree of the material after mineral self-repair.

[0135] Firstly, concrete materials with mineral self-healing properties are prepared. In Examples 3 and 4, the cementitious material is P O4 2.5 ordinary portland cement; the fine aggregate is river sand, and the fineness modulus is 2.2; the coarse aggregate is continuously graded from 5mm to 25mm; the expansion agent is UEA expansion agent; water reducer using polycarboxylate water reducer. The ratio of raw materials is as shown in Table 5:

[0136] table 5:

[0137]

[0138] After the test pieces were formed, Example 3 was placed in a concrete standard curing room for 28 days, and Example 4 was placed in an aqueous calcium hydroxide solution for 28 days.

[0139] The test method of embodiment 3 and 4 is consistent, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com