Unidirectional ceramic matrix composite thermal expansion coefficient prediction method considering damage evolution

A technology of thermal expansion coefficient and composite materials, which is applied in computer material science, electrical digital data processing, design optimization/simulation, etc., can solve the problem of affecting the thermal expansion coefficient, the inability to accurately predict the thermal expansion coefficient of unidirectional ceramic matrix composite materials, and changing the macroscopic deformation of materials and other issues to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in further detail now in conjunction with accompanying drawing.

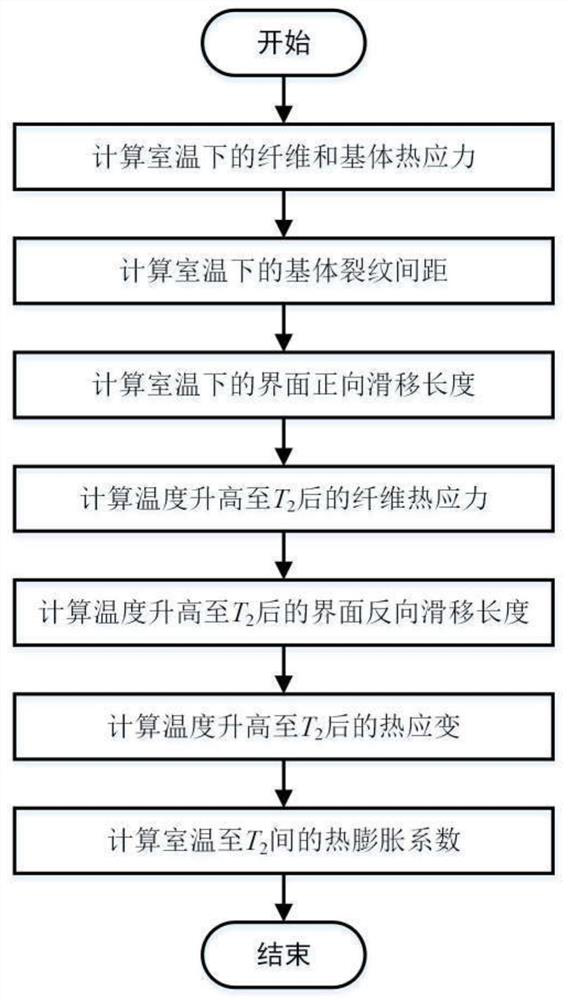

[0042] The present invention provides a method for predicting thermal expansion coefficient of unidirectional ceramic matrix composites considering damage evolution, such as figure 1As shown, the method includes the following steps:

[0043] Step 1: Calculate the room temperature T separately 1 Fiber thermal stress σ under f,1 and matrix thermal stress σ m,1 :

[0044]

[0045]

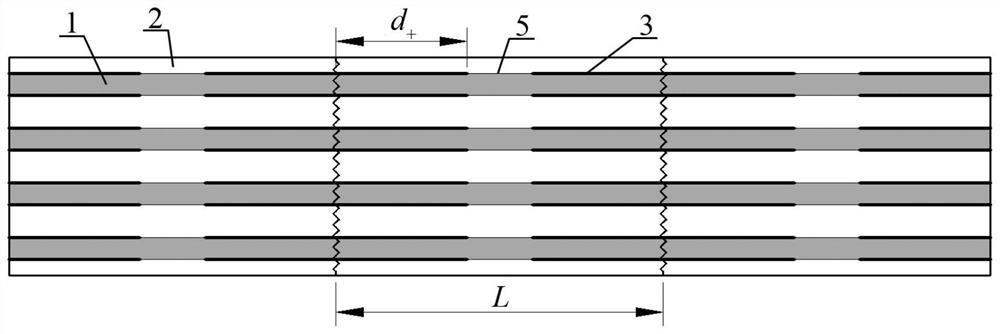

[0046] Step 2: If figure 2 Shown by the room temperature T 1 The matrix thermal stress σ under m,1 Calculate the matrix crack spacing L at room temperature.

[0047] Step 3: If figure 2 Shown by the room temperature T 1 Calculate the interfacial forward slip length at room temperature under the fiber thermal stress

[0048] Step 4: Calculate the temperature rise to T 2 Fiber thermal stress σ after f,2 :

[0049]

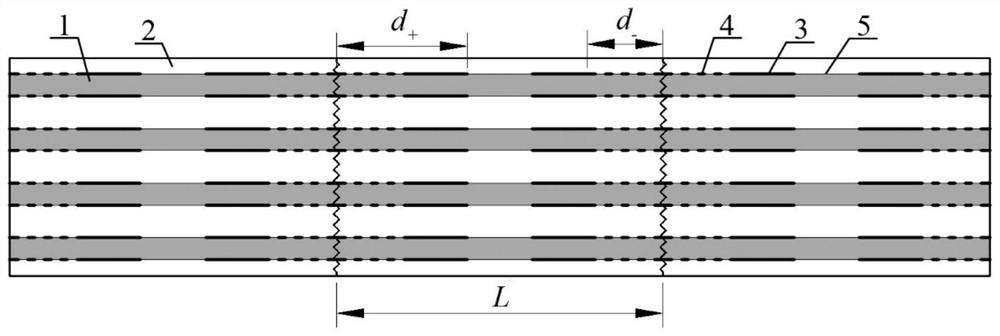

[0050] Step 5: If image 3 As shown, the calculated tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com