Stress control production process of high-strength aluminum alloy pipe

A production process and stress control technology, applied in metal extrusion control equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as large stress, ellipse, and pipe deformation, and reduce quenching residual stress and bending deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

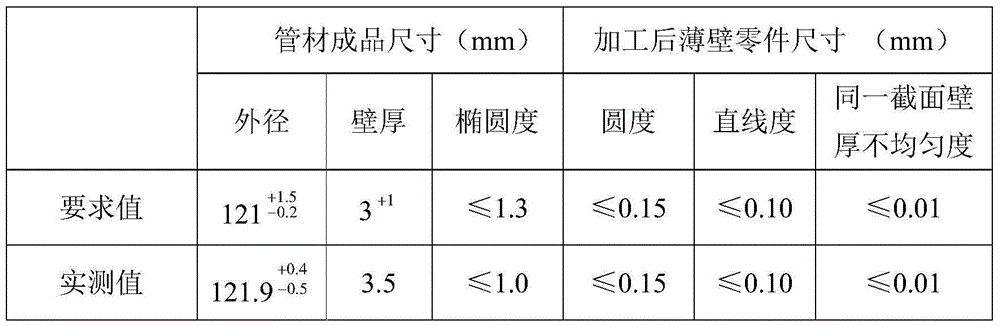

Image

Examples

Embodiment Construction

[0013] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

[0014] The high-strength aluminum alloy pipe stress control production process of the present invention comprises the following steps,

[0015] a. Select the extrusion die; check the surface and size of the extrusion die before installation, and the roundness tolerance of the die shall not exceed 0.10mm;

[0016] b. Preheat the extrusion die; preheat the extrusion barrel of the extrusion die to 400-450°C; further, preheat the extrusion barrel of the extrusion die to 400-430°C, and the holding time is not less than 120min .

[0017] c. Preheat the aluminum alloy hollow round ingot blank; preheat the ingot to 400-450°C, and control the temperature difference between the head and the tail of the ingot to ≤30°C; further, preheat the ingot to 400-420°C, control The temperature difference between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com