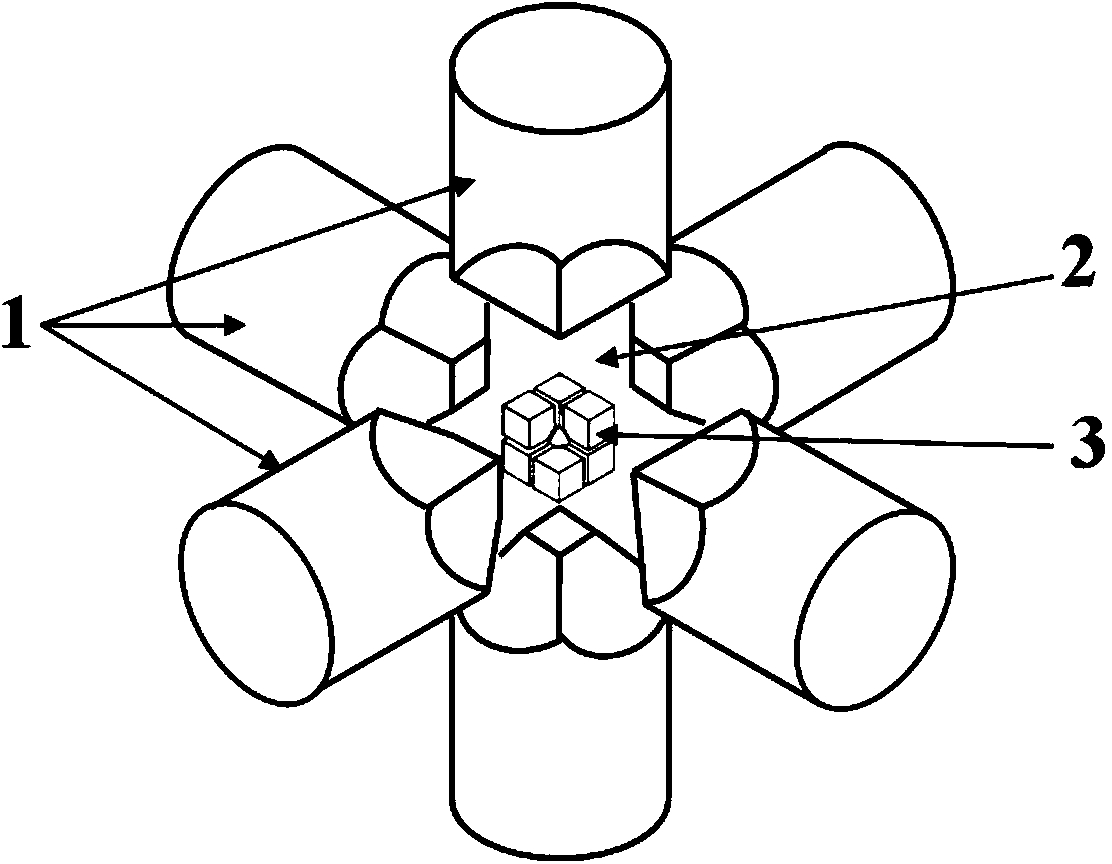

Secondary anvil and secondary pressurizing unit of octahedral pressure cavity static high-pressure device

A high-pressure device and octahedron technology, which is applied in the field of pressure devices, can solve problems such as damage to the static high-pressure device of the octahedral pressure chamber, and achieve the effects of reducing the probability of firing, increasing the maximum pressure, and enhancing the pressure sealing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

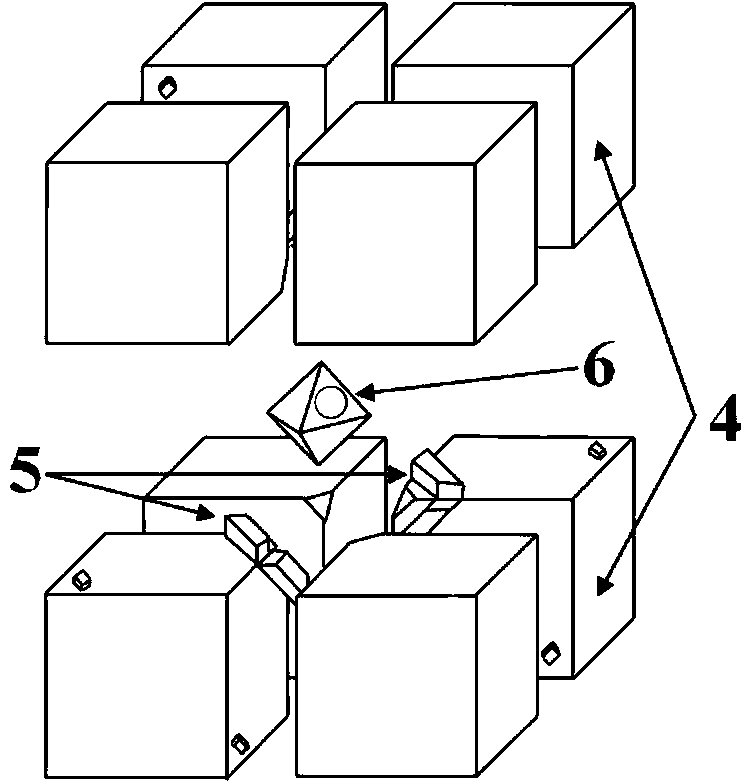

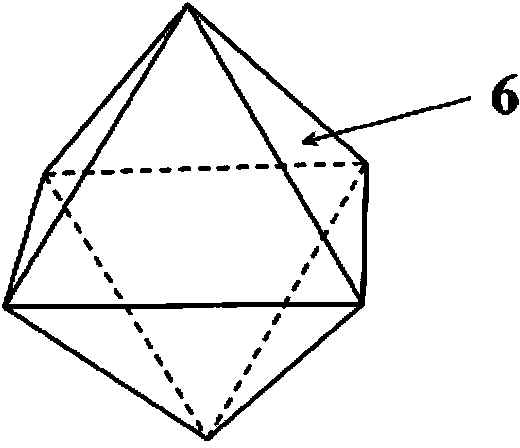

Embodiment 1

[0031] In this embodiment, the secondary anvil is made of tungsten carbide, such as Figure 7 , Figure 8 As shown, the anvil body is a cube, and the anvil surface 7 is an equilateral triangle surface formed by cutting off a corner on the cube anvil body, and a circle of outer ring surfaces 8 are arranged around the anvil body 7, and the outer ring surface 8 is composed of three It consists of trapezoidal slopes with the same shape and size. The upper bases of the three trapezoidal slopes are the three sides of the equilateral triangle anvil surface 7, and the lower bottoms of the three trapezoidal slopes form an equilateral triangle. The edge length of described cube anvil body is 18mm, and the side length of triangular anvil surface 7 is 3.5mm, and the included angle of triangular anvil surface 7 and anvil body top surface or bottom surface is 54 °, and the clamping angle of trapezoidal inclined surface and described anvil surface 7 The angle θ is 49°, and the height of the...

Embodiment 2

[0035] In the present embodiment, the manufacturing material of secondary anvil is identical with embodiment 1, and its shape is as follows Figure 7 , Figure 8As shown, the anvil body is a cube, and the anvil surface 7 is an equilateral triangle surface formed by cutting off a corner on the cube anvil body, and a circle of outer ring surfaces 8 are arranged around the anvil body 7, and the outer ring surface 8 is composed of three The trapezoidal slopes with the same shape and the same size are formed. The upper bottoms of the three trapezoidal slopes are three sides of the equilateral triangle anvil surface 7, and the lower bottoms of the three trapezoidal slopes form an equilateral triangle. The edge length of the cube anvil body is 18 mm. , the side length of the triangular anvil surface 7 is 2mm, the angle between the triangular anvil surface 7 and the top or bottom surface of the anvil body is 54°, the angle θ between the trapezoidal slope and the anvil surface 7 is 5°,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com